Thanks for sharing this information. I enjoy reading your posts and watching your videos. You're making progress and that is all that matters.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a diesel powered RHD TJ Wrangler (Picture Heavy)

- Thread starter RustyAutoholicGuy

- Start date

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Thanks for the level of detail. I'm watching your swap to decide if this is something i could pull off as well.Hey TJers,

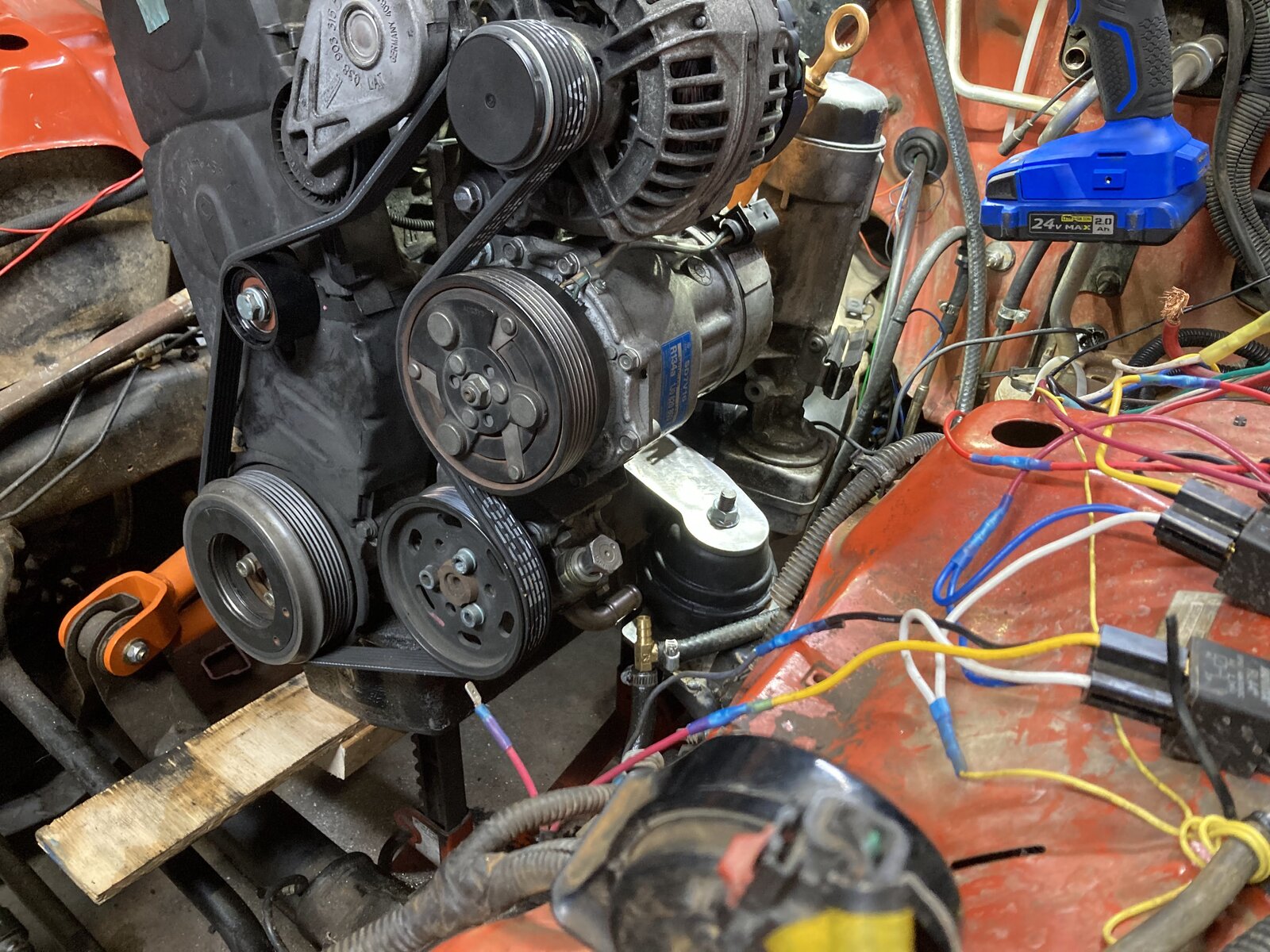

I got the BEW TDI Accessory Relocation Bracket from TDConversion installed successfully, but it was not as straight forward as I thought it might be. That being said, TDConversions/NorthWestFab replied to my emails about questions and for an instruction manual very quickly.

View attachment 295357

So a few things you should know if you are looking at using this kit on your swap. First you will need to remove your engine hoist mount, the engine mount on the front of the timing cover and the hard line pipe that run across the valve cover. While I wasn't planning on using any of these, I also didn't realize I needed to remove them when I first started.

View attachment 295358

Second The kit is well made and comes with all the hardware you need but I still found I had to grind a bit of the bracket so it would clear part of the cylinder head on my BEW TDI. The kit also doesn't come with instructions but you can email NorthWestFab/TDConversions and they have a set of instructions they can send to you.

View attachment 295359

Third you will need to modify (cut and grind) the original accessory bracket. First you will need to cut a section of the factory bracket so that it clears the thermostat housing that is supplied with the kit, you can not use the factory one as it will interfere with the AC compressor. Also you will need grind some one of the ribs on the back of the factory bracket to clear the fasteners that hold their bracket to the block.

Fourth you need to install the thermostat housing before you install your accessories. There is no way to get to the bolts once you have installed the bracket from TDConversions along with the original accessory bracket on your BEW TDI.

Fifth I wasn't able to use the supplied idler pulley in their kit to get the supplied double sided serpentine belt onto the accessories. Even after getting the instructions I wasn't able to get the belt one by removing one of the alternator bolts. My solution was to get a smaller idler pulley. I had one in my shop but I've order an even smaller one so the belt is easier to install. I found this to be my biggest headache on the project. I actually tried finding a longer belt first but there aren't many options for double sided serpentine belts.

View attachment 295360

Lastly I should mention that if you want to use this kit, you won't be able to use the original motor mount that is on the front of the engine to mount your TDI onto your frame. For me this wasn't an issue, I had planed on making other motor mounts, but I have seen plenty of people that use that front motor mount in their swaps.

With all of that said I've very pleased with the kit with all the clearances that it gave me for my swap. I no longer have to worry about the pumpkin on my Dana 30 front axle smashing into my accessories and it's is going to make it easier to fabricate motor mounts on the driver (my passenger) side of the engine.

View attachment 295368

Here is the video if you want to watch:

Thanks

Grant

Thanks for sharing this information. I enjoy reading your posts and watching your videos. You're making progress and that is all that matters.

Thank you so much @Wildman I've enjoyed sharing everything I've learned and encountered along the way!

Thanks for the level of detail. I'm watching your swap to decide if this is something i could pull off as well.

Sure thing and just realize that swapping with a manual transmission is 1000% easier than automatic. That being said I think the Ford 6r80 with the granny low first great and two over drives, one for highways and one for interstates, is going to work really well. It's basically a clutchless manual transmission compared to a traditional automatic like the 32rh that came in earlier TJs.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

I am with you, manual is not an option for a rock crawler IMO. I also like the NAG1 5 speed as an option to the 6R80.Sure thing and just realize that swapping with a manual transmission is 1000% easier than automatic. That being said I think the Ford 6r80 with the granny low first great and two over drives, one for highways and one for interstates, is going to work really well. It's basically a clutchless manual transmission compared to a traditional automatic like the 32rh that came in earlier TJs.

Hey TJers,

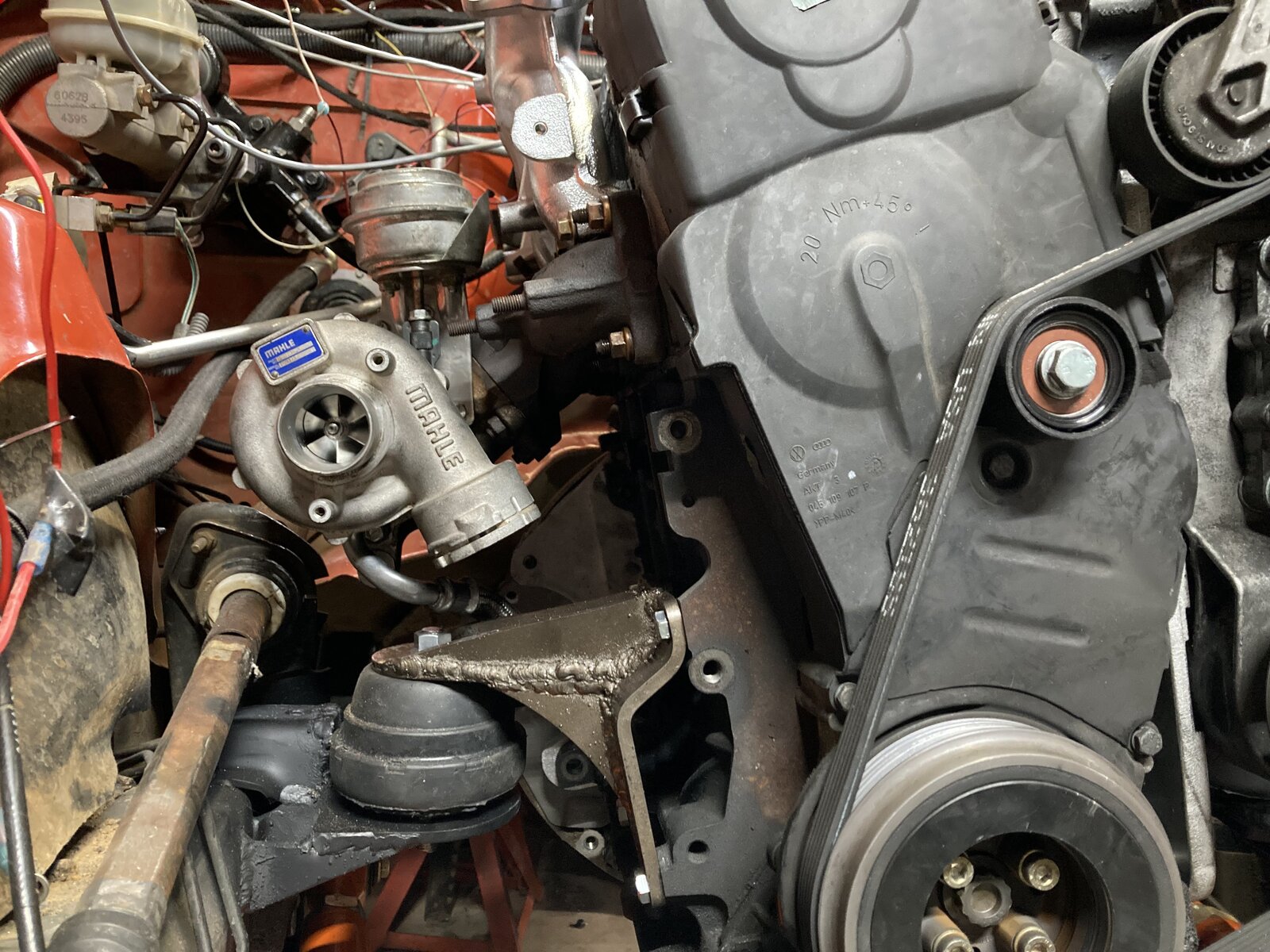

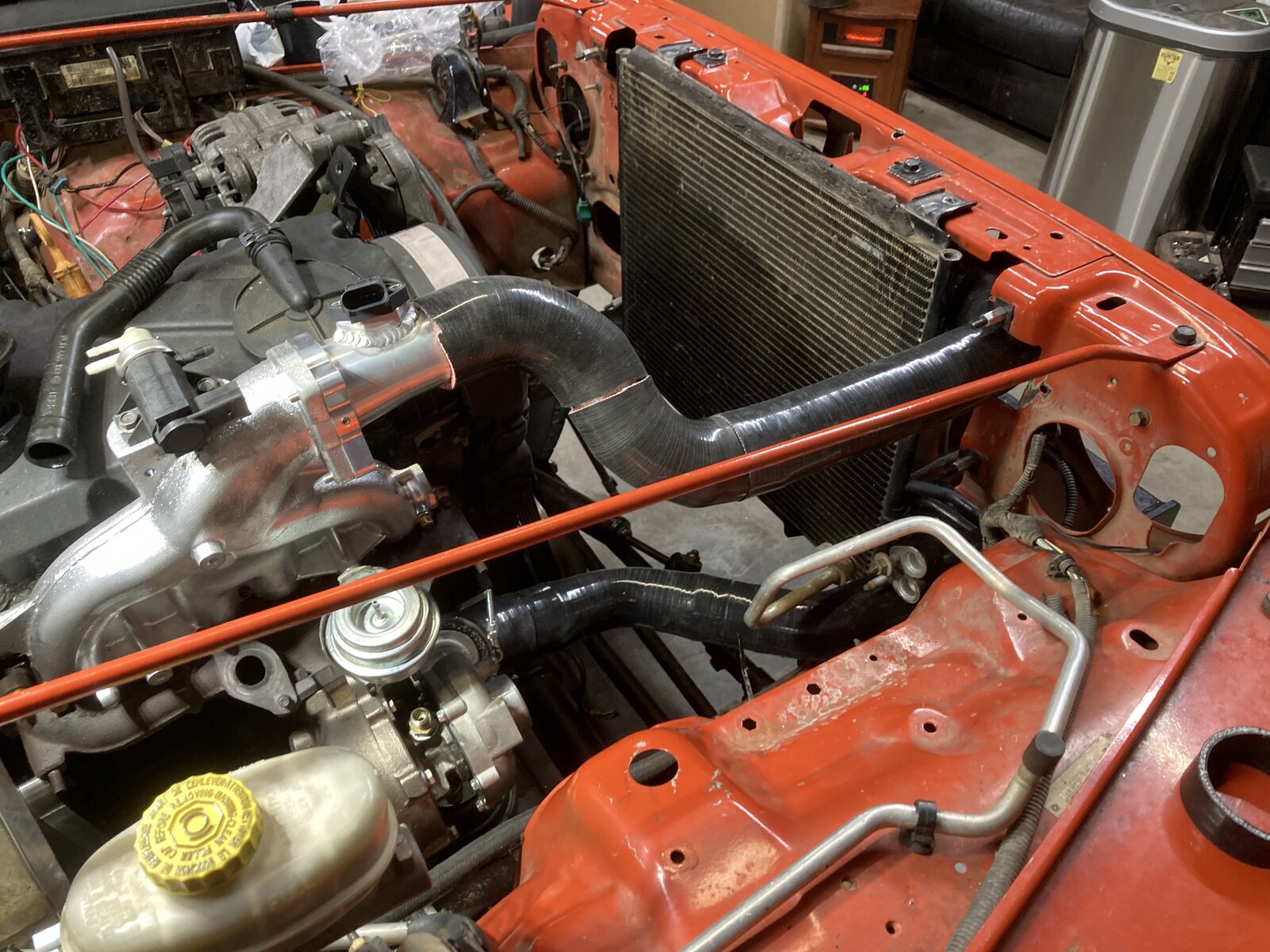

I successfully got my BEW TDI engine test fitted into my Right Hand Drive TJ Wrangler. Only took going to a turbo off a Passat BHW to make it work, but it fits.

First off I want to say thank you to the members of the TDI Swapped Trucks group, I asked for turbo recommendations and I got a slew of great responses. However one of my saved searches on FB Marketplace came up with a Passat TDI Turbo for sale with 50 miles on it for $200 and it came with the oil return line and support bracket. Decided to try it since it was so close to me (less than 20 minutes away) and it turned out to work great.

Having the turbo positioned slightly higher up and out vs the stock turbos being low really gave me all the clearance I needed to my steering components and motor mount perches on my frame to make this engine fit and bolt up to my Ford 6r80.

Next I'm going to start working on trying to figure out how to make motor mounts for the BEW TDI to my TJ Wrangler frame.

Here is the video if you want to watch:

Thanks

Grant

I successfully got my BEW TDI engine test fitted into my Right Hand Drive TJ Wrangler. Only took going to a turbo off a Passat BHW to make it work, but it fits.

First off I want to say thank you to the members of the TDI Swapped Trucks group, I asked for turbo recommendations and I got a slew of great responses. However one of my saved searches on FB Marketplace came up with a Passat TDI Turbo for sale with 50 miles on it for $200 and it came with the oil return line and support bracket. Decided to try it since it was so close to me (less than 20 minutes away) and it turned out to work great.

Having the turbo positioned slightly higher up and out vs the stock turbos being low really gave me all the clearance I needed to my steering components and motor mount perches on my frame to make this engine fit and bolt up to my Ford 6r80.

Next I'm going to start working on trying to figure out how to make motor mounts for the BEW TDI to my TJ Wrangler frame.

Here is the video if you want to watch:

Thanks

Grant

Hey TJers,

I got my motor mounts fabricated to mount my BEW TDI engine into my Right Hand Drive TJ Wrangler. I decided to go with hydraulic motor mounts using a combination of parts from both TD Conversions (now owned by NorthWestFab) and Doomsday Diesel to make everything fit.

Oddly enough out of everything involved with this BEW TDI swap the motor mounts have been what I've been the most concerned about making. Making the mounts for the Kubota was relatively simple compared to the BEW TDI.

While I don't think I mentioned it before, the Kubota being a mechanically injected diesel would shake and vibrate my TJ Wrangler pretty heavily at idle. Since I was swapping to a different diesel engine I wanted to see what I could do to eliminate the shake and rattles, even though I know going a computer controlled TDI engine would help immensely.

I decided early on I was going to try a set of hydraulic motor mounts on this engine setup. The downside to that is I didn't realize just how big this mounts are compared to a bushing and sleeve style mount. Making room for these motor mounts ended up being quite the challenge to figure out.

What I finally realized after looking at it for days in my engine bay was that I could cut my factory motor mount perches in half to reduce how tall they were and use the remaining metal left on the frame to weld my new lower mounts for the hydraulic motor mounts.

After that the rest was pretty straight forward, I did have to clock my turbo and cut/customize the other motor mount pieces I had gotten to get everything to fit. After tack welding everything into place and checking all my clearances, I added support gussets to everything before welding all the mounts together and painting everything.

Here is the video if you want to watch:

Thanks

Grant

I got my motor mounts fabricated to mount my BEW TDI engine into my Right Hand Drive TJ Wrangler. I decided to go with hydraulic motor mounts using a combination of parts from both TD Conversions (now owned by NorthWestFab) and Doomsday Diesel to make everything fit.

Oddly enough out of everything involved with this BEW TDI swap the motor mounts have been what I've been the most concerned about making. Making the mounts for the Kubota was relatively simple compared to the BEW TDI.

While I don't think I mentioned it before, the Kubota being a mechanically injected diesel would shake and vibrate my TJ Wrangler pretty heavily at idle. Since I was swapping to a different diesel engine I wanted to see what I could do to eliminate the shake and rattles, even though I know going a computer controlled TDI engine would help immensely.

I decided early on I was going to try a set of hydraulic motor mounts on this engine setup. The downside to that is I didn't realize just how big this mounts are compared to a bushing and sleeve style mount. Making room for these motor mounts ended up being quite the challenge to figure out.

What I finally realized after looking at it for days in my engine bay was that I could cut my factory motor mount perches in half to reduce how tall they were and use the remaining metal left on the frame to weld my new lower mounts for the hydraulic motor mounts.

After that the rest was pretty straight forward, I did have to clock my turbo and cut/customize the other motor mount pieces I had gotten to get everything to fit. After tack welding everything into place and checking all my clearances, I added support gussets to everything before welding all the mounts together and painting everything.

Here is the video if you want to watch:

Thanks

Grant

The compactness of that engine is going to make it so easy to work on!

The compactness of that engine is going to make it so easy to work on!

That is the hope or better yet I won't have to work on it at all

I got some work done over the Christmas holiday. After adding as many gussets as I could to my motor mounts and frame mount perches, I finally feel like I'm making progress. I have the BEW TDI mounted and installed into my RHD TJ Wrangler.

After several people mentioned that they had used the same DIY motor mount kit I used and had the mounts bend on them, I took their advise and spent the time to add more gussets on both the motor mounts that bolt to the TDI engine and frame mount perches as well.

After I got all the additional gussets welded into place, I installed the new torque converter I had custom made from Circle D and installed it onto my Ford 6r80 6-speed automatic.

After getting the torque converter installed, I took the bellhousing and crankshaft adapter off the BEW TDI to put thread lock on all the fasteners. Once that was done, it was just a matter of redoing the chain on my engine hoist to get the BEW TDI in the correct position so I could easily mate it to the Ford 6r80 automatic transmission.

Once the engine and transmission were bolted together, I went about installing the motors which worked out perfectly. Triple checking all my clearances and measurements paid off, everything fit first try surprisedly.

Now I just need to finish the last 15% off this build which is going to be wiring, exhaust, coolant lines and intercooler plumbing and I should be done . . . I hope.

Here is the video if you want to watch it:

Thanks

Grant

Hey Tjers,

I think the end is insight for my BEW TDI TJ Wrangler build, the driveline is all in place and now it's just tackling all the smaller parts of the swap to get my diesel powered Wrangler running.

I started out by pulling out the custom wiring harness I got from Fast Forward Automative so I could familiarize myself where everything went. In looking at the harness I realized there were a few things I was missing from my donor vehicle so I spent some time off camera grabbing those missing pieces.

After a few days I had a few parts come in so I mounted the PD150 intake and my BHW exhaust and turbo to my BEW TDI which ended up being a slight jigsaw puzzle to put together. One step a time, I'll get to hear my TJ running again soon.

Here is the video if you want to watch it:

Thanks

Grant

I think the end is insight for my BEW TDI TJ Wrangler build, the driveline is all in place and now it's just tackling all the smaller parts of the swap to get my diesel powered Wrangler running.

I started out by pulling out the custom wiring harness I got from Fast Forward Automative so I could familiarize myself where everything went. In looking at the harness I realized there were a few things I was missing from my donor vehicle so I spent some time off camera grabbing those missing pieces.

After a few days I had a few parts come in so I mounted the PD150 intake and my BHW exhaust and turbo to my BEW TDI which ended up being a slight jigsaw puzzle to put together. One step a time, I'll get to hear my TJ running again soon.

Here is the video if you want to watch it:

Thanks

Grant

Great  to see it all coming together for you.

to see it all coming together for you.

Looking forward to when you get it running and driving.

Looking forward to when you get it running and driving.

Hey TJers,

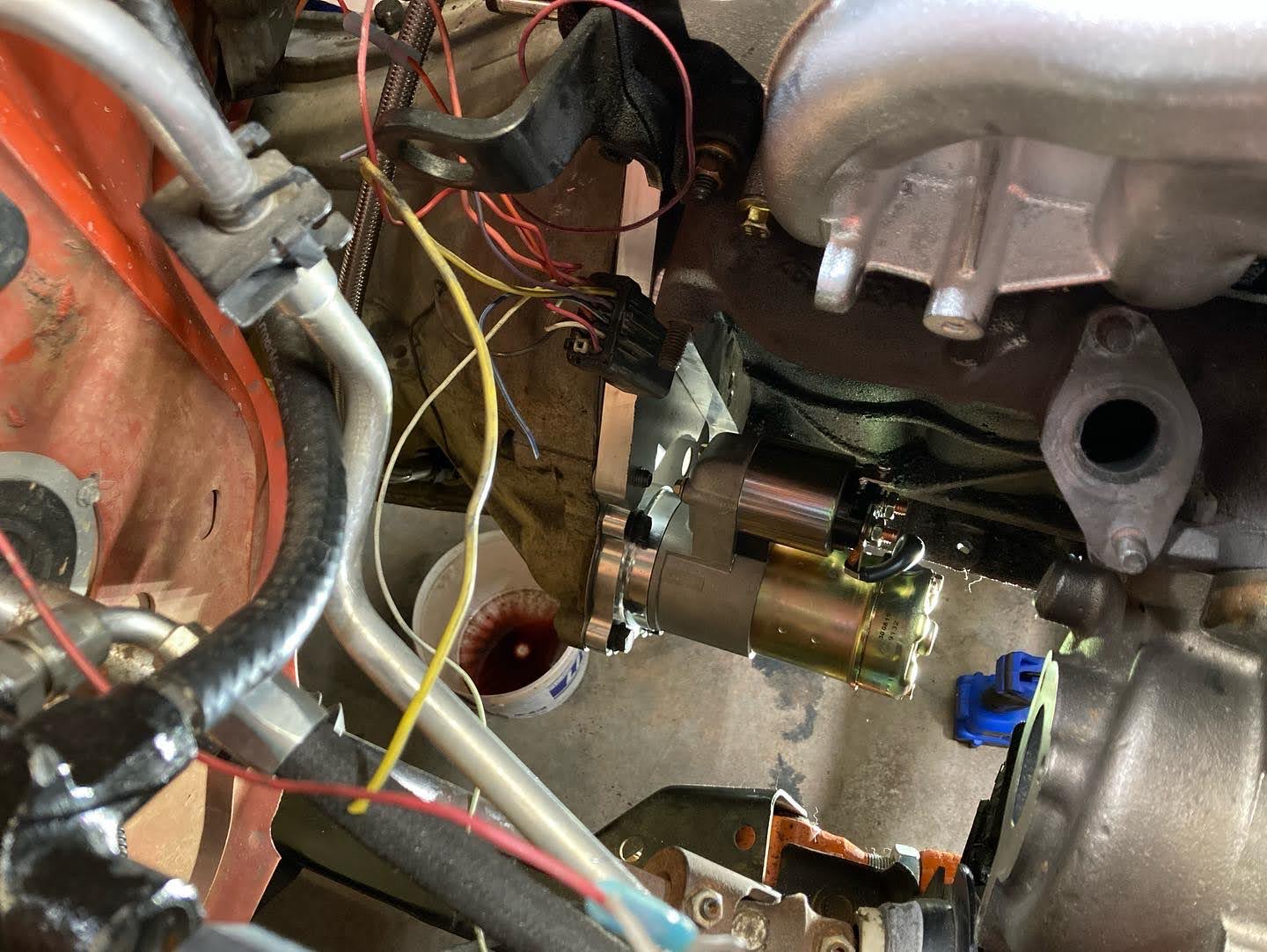

I realized to do a test fire on my TDI swapped TJ Wrangler I need to button up all the stuff on my Ford 6r80 6-speed automatic transmission. So I got the starter, torque converter fasteners and dipstick all installed.

The starter was a straight forward install and having one where I could clock it was very helpful as well. I decided to clock the starter so the solenoid would be away from the exhaust and closer to the block of my BEW TDI.

After that I went about installing the provided fasteners from Circle D into my custom torque converter. This actually ended up being much simpler compared to my Kubota V2403 since the oil pan isn't as low on the TDI, made for a quick job.

Finally I installed the B&M locking dipstick on the Ford 6r80. The factory dipstick is a stubbed piece which is not easy to access and I would have had to reach around my exhaust to check the fluid or add fluid to the transmission while it was running. While it was expensive, a bit over $220 shipped, the flexible locking dipstick from B&M it was well worth it for the connivence it'll over me in the future as well.

Next I'll be working on the power steering lines for my brakes and steering. After that is wrapped up and finished, onto wiring so I can test fire my BEW TDI engine in my TJ Wrangler.

Here is the video if you want to watch it:

Let me know what you think!

Grant

I realized to do a test fire on my TDI swapped TJ Wrangler I need to button up all the stuff on my Ford 6r80 6-speed automatic transmission. So I got the starter, torque converter fasteners and dipstick all installed.

The starter was a straight forward install and having one where I could clock it was very helpful as well. I decided to clock the starter so the solenoid would be away from the exhaust and closer to the block of my BEW TDI.

After that I went about installing the provided fasteners from Circle D into my custom torque converter. This actually ended up being much simpler compared to my Kubota V2403 since the oil pan isn't as low on the TDI, made for a quick job.

Finally I installed the B&M locking dipstick on the Ford 6r80. The factory dipstick is a stubbed piece which is not easy to access and I would have had to reach around my exhaust to check the fluid or add fluid to the transmission while it was running. While it was expensive, a bit over $220 shipped, the flexible locking dipstick from B&M it was well worth it for the connivence it'll over me in the future as well.

Next I'll be working on the power steering lines for my brakes and steering. After that is wrapped up and finished, onto wiring so I can test fire my BEW TDI engine in my TJ Wrangler.

Here is the video if you want to watch it:

Let me know what you think!

Grant

Hey TJers,

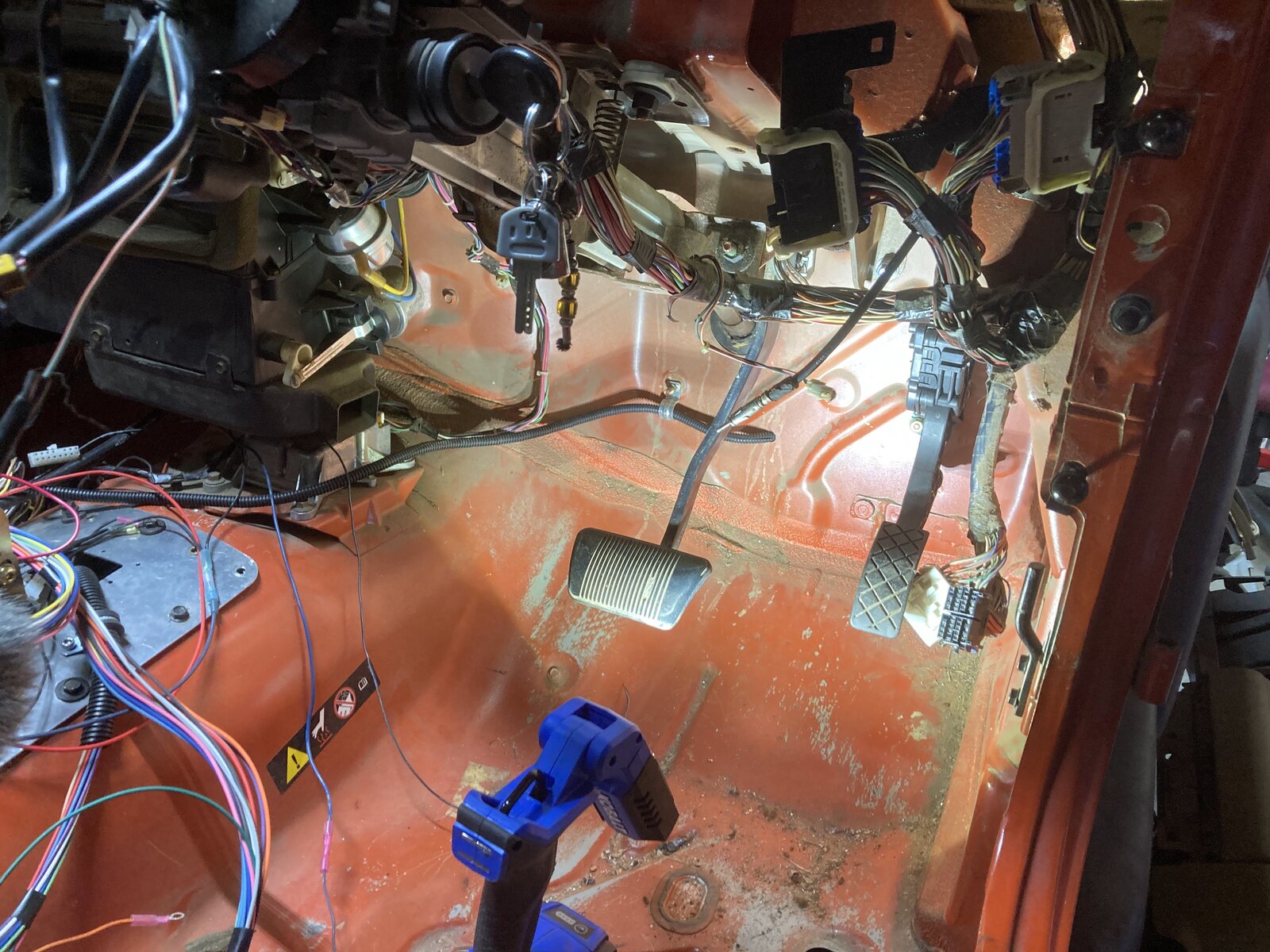

I started the process of installing the BEW TDI wiring harness from, ECU and throttle pedal into my diesel swap TJ Wrangler project. Even with a custom made wiring harness this is going to take a while.

I found out that you really want to mount the TDI ECU inside the cab since it's not waterproof like the factory Jeep ECU. So I decided to remove the dashboard, again, so I had as much room to work with as possible.

Once the Dashboard was out, I went about installing the throttle pedal first, since that really could only be mounted in so many places. I could move the wiring harness and ECU to accommodate it's location. Surprisingly I was able to reuse one of the original mounting stubs for the original throttle pedal.

Next I turned my attention to the TDI ECU. There are 4 mounting holes on the ECU that I ended up tapping with a M6x1.00 thread so I could put rubber vibration isolators onto. I tried reusing the ECU mount out of my parts Beetle but all the plastic clips were brittle and broke. I ended up mounting the ECU to the left of my steering column underneath my dash.

Next the wiring. Originally the plan was to have the wiring wrap underneath my steering sector shaft. However when I mounted the ECU, it became apparent that routing the wiring harness over the brake pedal bracket was going to be the better route.

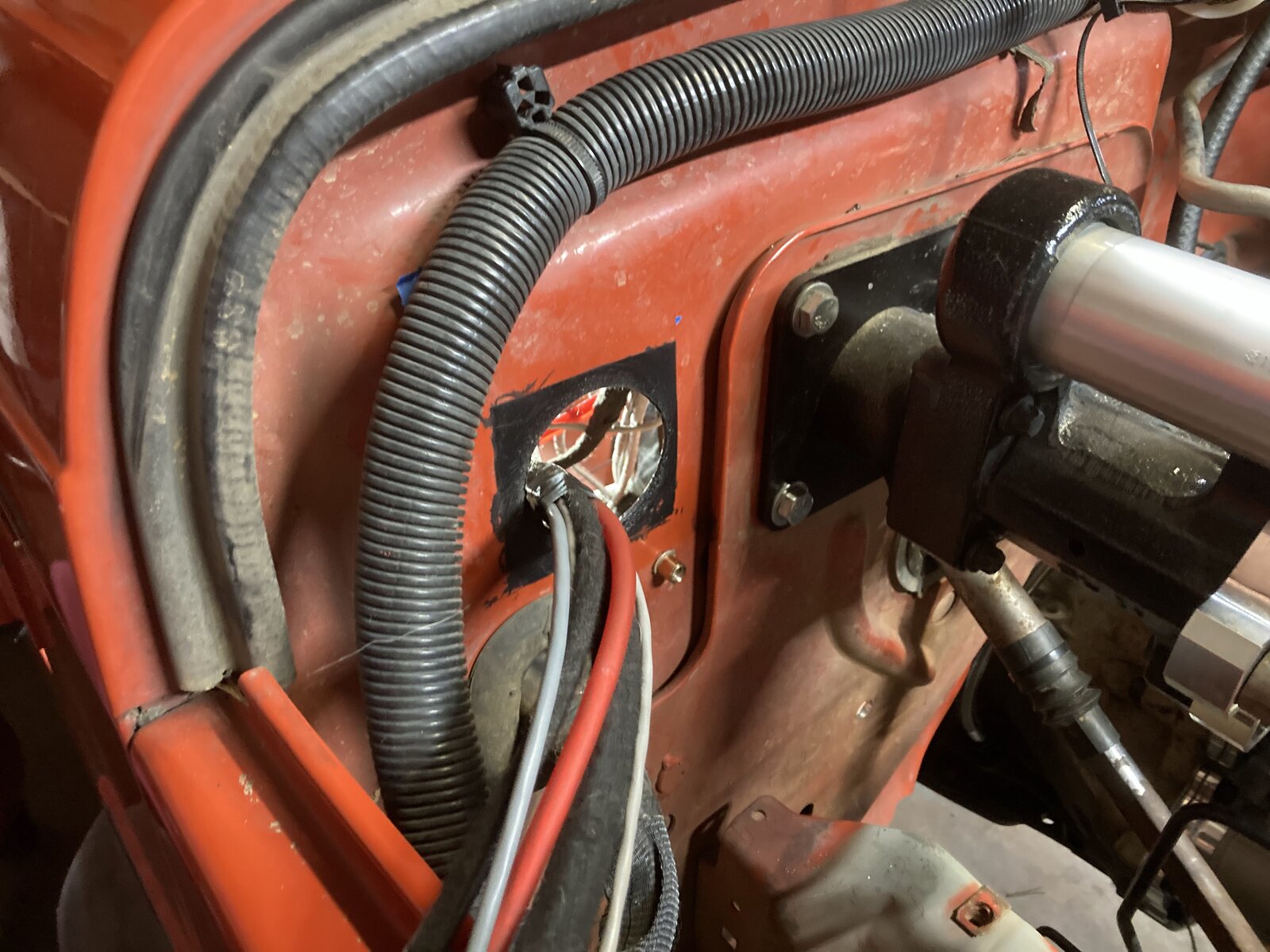

Finally I have drilled a hole in the firewall to pass through wiring harness from the interior to the engine bay. I'm going to be using a split gourmet to seal the hole in the firewall once I get everything tested and wired.

Next steps is to wire up everything temporarily and test everything to see if I can get the engine to spin over with the keys and possibly try test firing the BEW TDI to see if the ECU and wiring harness are working correctly.

Here is the video if you want to watch it:

Thanks

Grant

I started the process of installing the BEW TDI wiring harness from, ECU and throttle pedal into my diesel swap TJ Wrangler project. Even with a custom made wiring harness this is going to take a while.

I found out that you really want to mount the TDI ECU inside the cab since it's not waterproof like the factory Jeep ECU. So I decided to remove the dashboard, again, so I had as much room to work with as possible.

Once the Dashboard was out, I went about installing the throttle pedal first, since that really could only be mounted in so many places. I could move the wiring harness and ECU to accommodate it's location. Surprisingly I was able to reuse one of the original mounting stubs for the original throttle pedal.

Next I turned my attention to the TDI ECU. There are 4 mounting holes on the ECU that I ended up tapping with a M6x1.00 thread so I could put rubber vibration isolators onto. I tried reusing the ECU mount out of my parts Beetle but all the plastic clips were brittle and broke. I ended up mounting the ECU to the left of my steering column underneath my dash.

Next the wiring. Originally the plan was to have the wiring wrap underneath my steering sector shaft. However when I mounted the ECU, it became apparent that routing the wiring harness over the brake pedal bracket was going to be the better route.

Finally I have drilled a hole in the firewall to pass through wiring harness from the interior to the engine bay. I'm going to be using a split gourmet to seal the hole in the firewall once I get everything tested and wired.

Next steps is to wire up everything temporarily and test everything to see if I can get the engine to spin over with the keys and possibly try test firing the BEW TDI to see if the ECU and wiring harness are working correctly.

Here is the video if you want to watch it:

Thanks

Grant

Hey TJers,

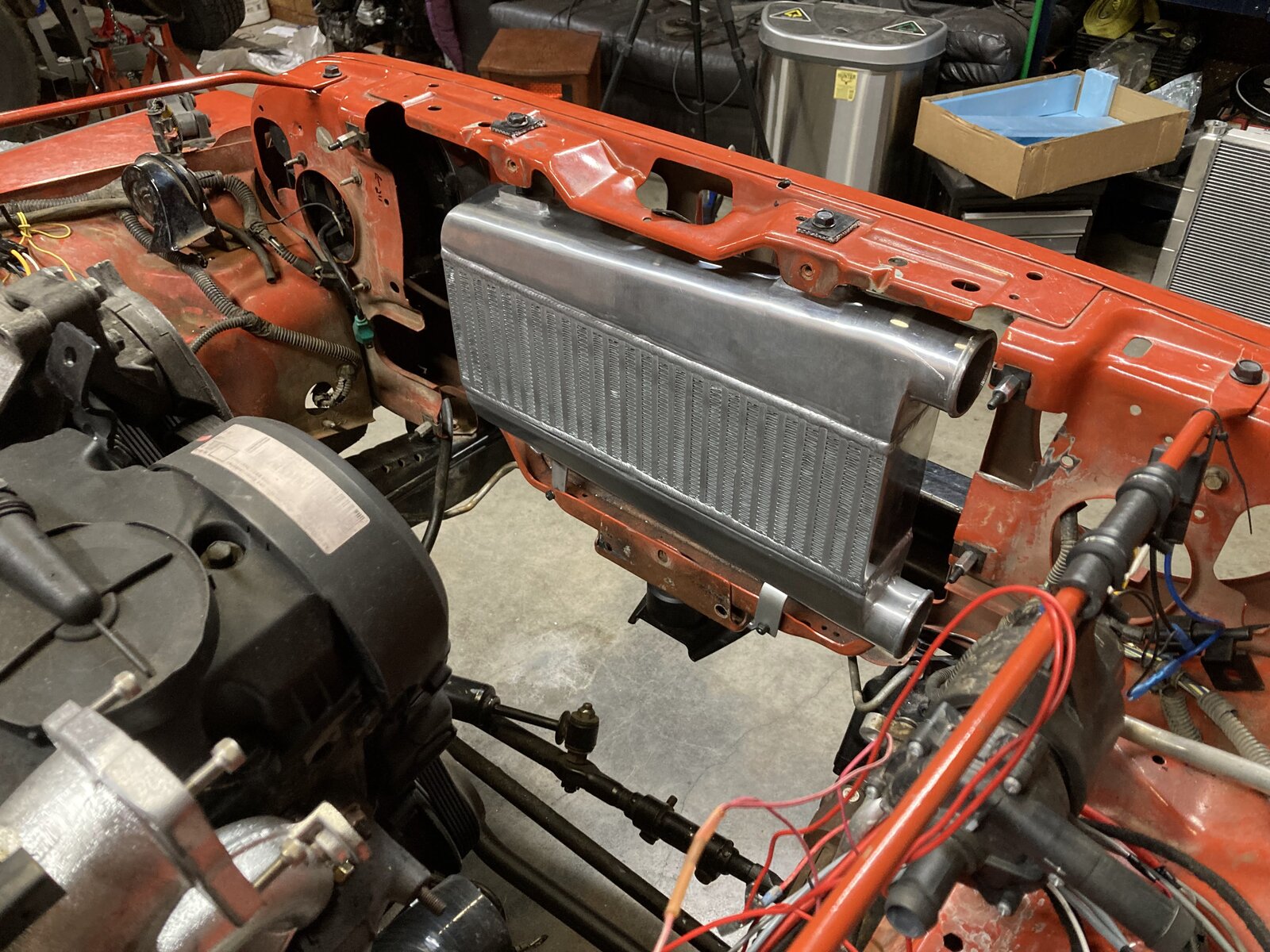

Decided to go with an air-to-air intercooler setup on BEW TDI diesel swap TJ Wrangler build. Originally I was going to be running a water-to-air setup but decided to switch to a simplier setup instead. To make the intercooler fit I knew I was going to have to start cutting up my front grill on my TJ.

The intercooler I went with ended up being 19x12x3.5 for it's dimensions with both the inlet and outlet on the same side. This made plumbing to the BEW TDI much simplier. Here is the link for the intercooler I used: https://www.siliconeintakes.com/fro...-p-208.html?osCsid=val14qm97pmcn3ib8lhpql4nn7

I've been hesitant ever since I started this build to start cutting up my TJ Wrangler, I think in the back of my mind I always had the option of going back to stock. However after cutting the tub for the fuel tank access panel, cutting up the original motor mount perches and drilling a 2-14" hole through my firewall, I've since realized it wasn't that big of a deal.

To make the intercooler fit I did have to cut both my front grill and the radiator support bracket as well to clear the upper and lower intercooler pipes. It really was a case of just taking my time, triple checking everything and making the smallest cuts possible. It's always easier to cut more metal than to have to replace metal you didn't mean to cut.

As for mounting the intercooler in the grill, I did run into a few issues I hadn't thought of. Specifically I had to remove the center hood safety latch so that the hood would close. Also the first set of holes I drilled to hold the intercooler inside of the grill, the bolts would interfere with the hood shutting as well.

Once I got the intercooler mounted where the hood closed correctly, I turned my attention to routing the boost piping from the intercooler to the turbo and intake on my BEW TDI. Interestingly enough because I spent so much time making sure the intercooler would clear it made routing the intercooler piping very simple.

Here is the video if you want to watch:

Let me know what you think!

Grant

Decided to go with an air-to-air intercooler setup on BEW TDI diesel swap TJ Wrangler build. Originally I was going to be running a water-to-air setup but decided to switch to a simplier setup instead. To make the intercooler fit I knew I was going to have to start cutting up my front grill on my TJ.

The intercooler I went with ended up being 19x12x3.5 for it's dimensions with both the inlet and outlet on the same side. This made plumbing to the BEW TDI much simplier. Here is the link for the intercooler I used: https://www.siliconeintakes.com/fro...-p-208.html?osCsid=val14qm97pmcn3ib8lhpql4nn7

I've been hesitant ever since I started this build to start cutting up my TJ Wrangler, I think in the back of my mind I always had the option of going back to stock. However after cutting the tub for the fuel tank access panel, cutting up the original motor mount perches and drilling a 2-14" hole through my firewall, I've since realized it wasn't that big of a deal.

To make the intercooler fit I did have to cut both my front grill and the radiator support bracket as well to clear the upper and lower intercooler pipes. It really was a case of just taking my time, triple checking everything and making the smallest cuts possible. It's always easier to cut more metal than to have to replace metal you didn't mean to cut.

As for mounting the intercooler in the grill, I did run into a few issues I hadn't thought of. Specifically I had to remove the center hood safety latch so that the hood would close. Also the first set of holes I drilled to hold the intercooler inside of the grill, the bolts would interfere with the hood shutting as well.

Once I got the intercooler mounted where the hood closed correctly, I turned my attention to routing the boost piping from the intercooler to the turbo and intake on my BEW TDI. Interestingly enough because I spent so much time making sure the intercooler would clear it made routing the intercooler piping very simple.

Here is the video if you want to watch:

Let me know what you think!

Grant

Nice work. Definitely different.

What are you using for a cooling fan? Are you still running A/C?

What are you using for a cooling fan? Are you still running A/C?

Nice work. Definitely different.

What are you using for a cooling fan? Are you still running A/C?

So I'm running a 17" Two-Speed Derale fan that is 1800cfm on low and 2400cfm on high. I will be running AC as well, though initially when I get it running I won't have the lines made for it, but I'll have all the major components in place.

Just food for thought: That intercooler adds a lot of distance / resistance for that fan to pull air through. I ran that exact Derale fan (23 amps, as I recall) on my rig pulling through the radiator, the A/C condensor, and another layer of steering and tranny coolers. It was not keeping up. I wound up switching to a more powerful Spal brushless fan which pulls something like 41 amps. That did the trick.So I'm running a 17" Two-Speed Derale fan that is 1800cfm on low and 2400cfm on high. I will be running AC as well, though initially when I get it running I won't have the lines made for it, but I'll have all the major components in place.

My guess is that my rig puts out a bit more heat that your new mill will, so you will likely be fine. That Derale is a good unit. Just pay close attention to your temps when you get it going.

Great build - I'm really enjoying it.

Jeff

Just food for thought: That intercooler adds a lot of distance / resistance for that fan to pull air through. I ran that exact Derale fan (23 amps, as I recall) on my rig pulling through the radiator, the A/C condensor, and another layer of steering and tranny coolers. It was not keeping up. I wound up switching to a more powerful Spal brushless fan which pulls something like 41 amps. That did the trick.

My guess is that my rig puts out a bit more heat that your new mill will, so you will likely be fine. That Derale is a good unit. Just pay close attention to your temps when you get it going.

Great build - I'm really enjoying it.

Jeff

Hey Jeff, thanks for the feedback. I've been fighting temps since I had a Kubota in my TJ though the Derale seemed to keep up just fine, I'll check out the Spal fan just in case as well, it's always good to know I have options to go to!

Hey Tjers,

Decided to take a small break from the diesel swap on my TJ Wrangler to install a Warn M8274 winch that I had acquired last March. I realize there are other lower profile winches out there but I've always loved the look of the M8274.

I ended up purchasing Warn's mount plate for a TJ Wrangler to install the 8274 onto the front of my TJ Wrangler. I did have to remove the front receiver hitch to install the winch mount plate, but that was a simple enough process.

The Warn winch mount is well made and comes with all the fasteners that are required to attach the mount plate to the TJ Wrangler frame. Installing the 8274 winch onto the winch plate was straight forward as well, you just have to be mindful of the square nuts that go into the 8274 winch, they didn't always want to line up perfectly with the bolts.

When I purchased the 8274 winch, I got two different synthetic lines, the line I would prefer to run is way too long, and the line I have on it now isn't strong enough for the winch, but I want to see what it would look like with a line installed. I've seen some newer style synthetic rope lines like what Nate uses on Dirty Lifestyle that I'm going to be researching soon as a possible upgrade for my Warn 8274.

Here is the video if you want to watch:

Let me know what you think!

Grant

Decided to take a small break from the diesel swap on my TJ Wrangler to install a Warn M8274 winch that I had acquired last March. I realize there are other lower profile winches out there but I've always loved the look of the M8274.

I ended up purchasing Warn's mount plate for a TJ Wrangler to install the 8274 onto the front of my TJ Wrangler. I did have to remove the front receiver hitch to install the winch mount plate, but that was a simple enough process.

The Warn winch mount is well made and comes with all the fasteners that are required to attach the mount plate to the TJ Wrangler frame. Installing the 8274 winch onto the winch plate was straight forward as well, you just have to be mindful of the square nuts that go into the 8274 winch, they didn't always want to line up perfectly with the bolts.

When I purchased the 8274 winch, I got two different synthetic lines, the line I would prefer to run is way too long, and the line I have on it now isn't strong enough for the winch, but I want to see what it would look like with a line installed. I've seen some newer style synthetic rope lines like what Nate uses on Dirty Lifestyle that I'm going to be researching soon as a possible upgrade for my Warn 8274.

Here is the video if you want to watch:

Let me know what you think!

Grant

I am a HUGE 8274 fan and have ran one on my last 4 Jeeps and on a few other rigs too. How long is the other line that you have. I've always ran 150' of either cable or rope.

I've got to rebuild mine before i reinstall it on my rig.

I've got to rebuild mine before i reinstall it on my rig.

I am a HUGE 8274 fan and have ran one on my last 4 Jeeps and on a few other rigs too. How long is the other line that you have. I've always ran 150' of either cable or rope.

I've got to rebuild mine before i reinstall it on my rig.

I'm not sure, but it was getting bound up against the mount plate. I might try getting that line installed again, maybe I wasn't getting it spooled tight enough on the drum, but I would prefer something I don't have to be super organized with if that makes sense.