Hey TJers,

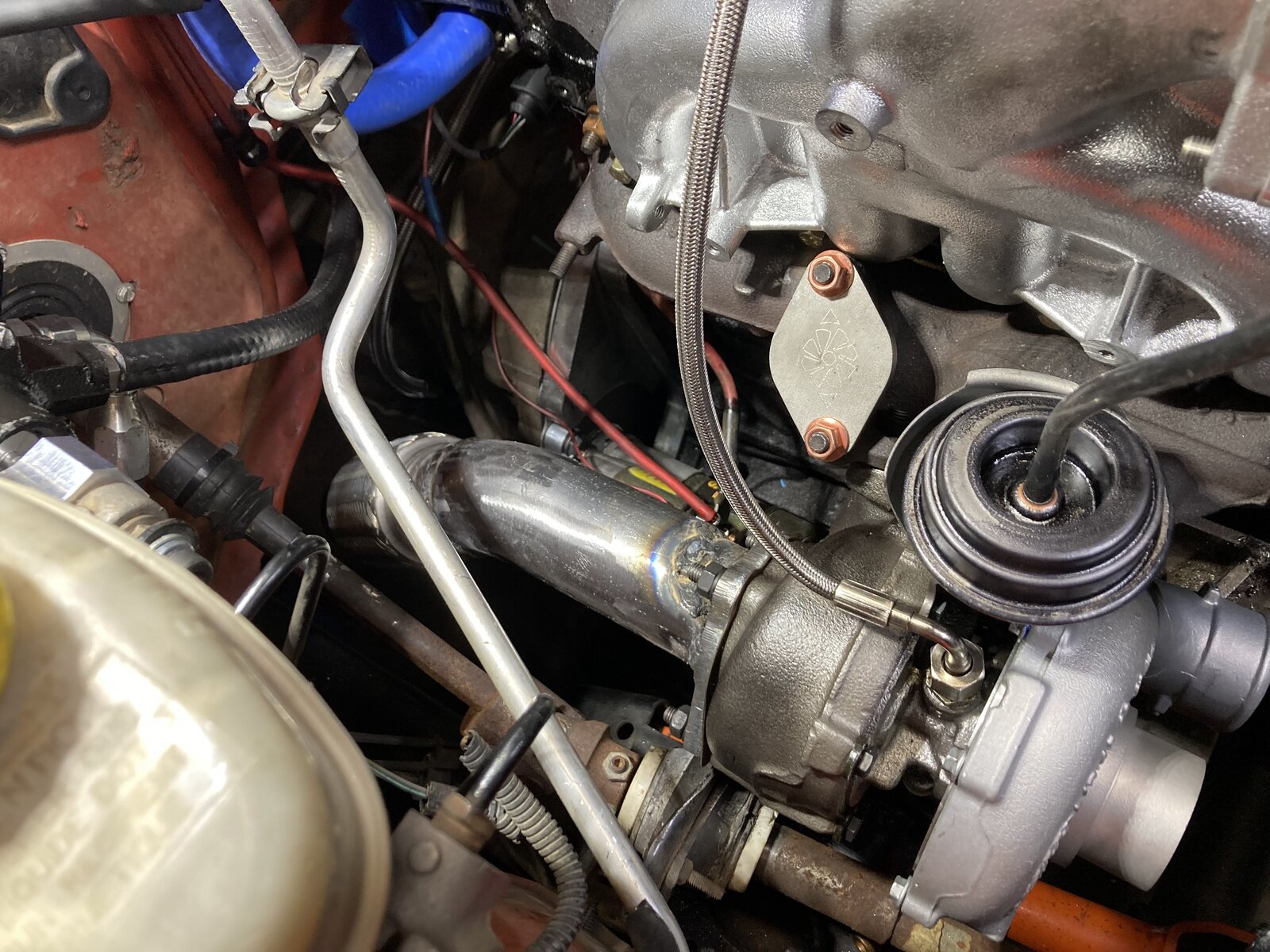

I got my new GT1752v turbo in and installed into my BEW TDI swapped TJ Wrangler. The turbo bolted up and fit perfectly. Once the turbo was in place I went about getting it all plumbed for exhaust, oil, vacuum and intercooler piping. Though in getting the pictures ready for this post I realized I forgot to take pictures of the new turbo before I installed it.

It would have been really nice to run a newer style turbo on my swap but at this point, almost 4 years into this build, I'm just wanting my TJ back on the road and more importantly back on the trails. The GT1752v was quite literally a bolt on, there were no issues getting it installed at all.

Next I turned my attention to making a downpipe for the turbo to connect up to the rest of my exhaust system. I had gotten a flange made from KubotaSwappers so that I could fabricate a downpipe that would connect to the back of my turbo. I was planning on using my plasma cutting table to make one myself but my plasma cutter is not working at the moment.

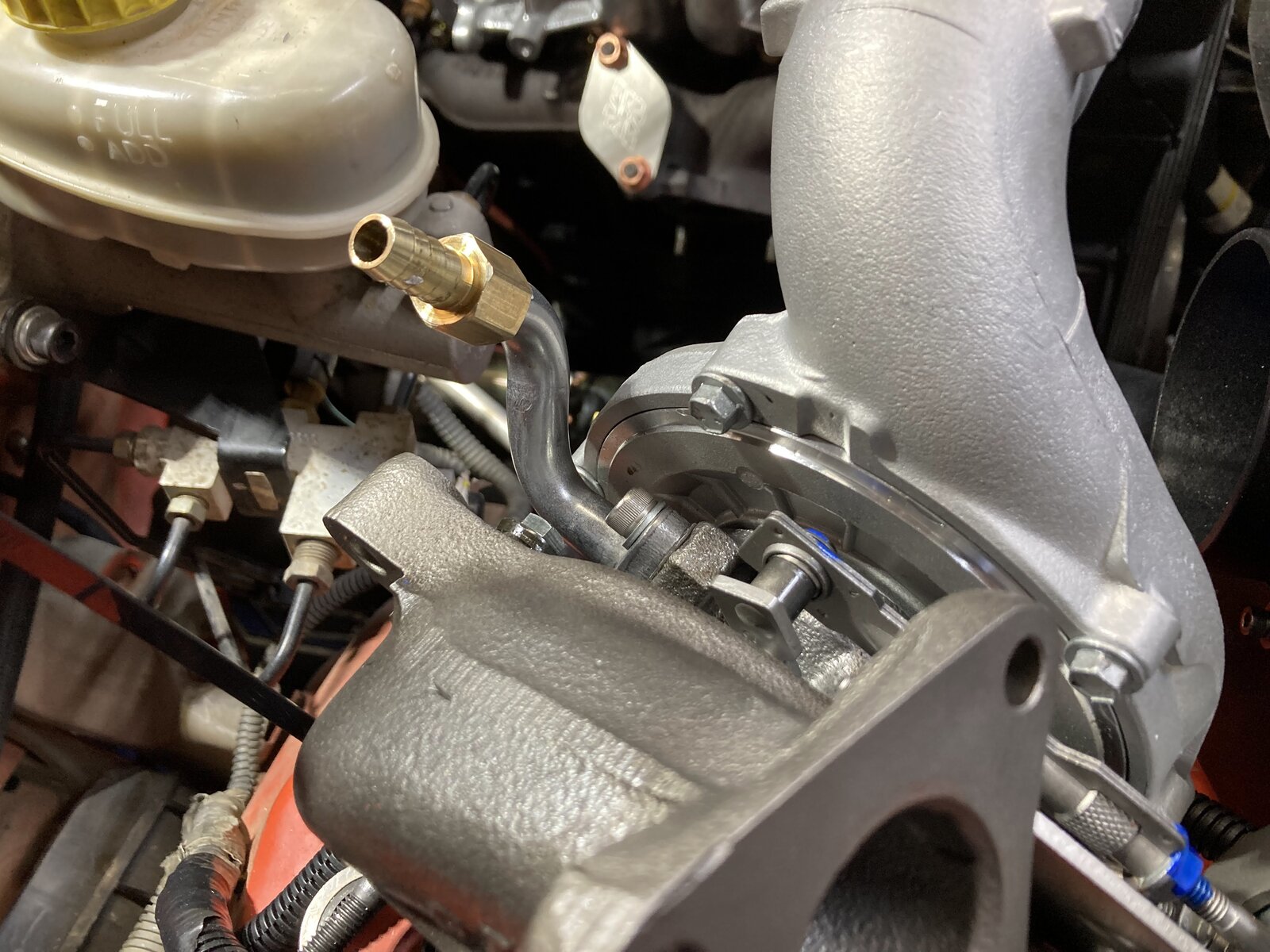

With the exhaust all figured out, I then went about figuring out how to hook up the oiling system for the turbo. I had ordered a kit so that I could put together my own oil return line from the turbo to the TDI block. However the placement of my motor mounts interfered with the supplied fitting for the turbo. I ended up modifying the original return line by using a ¼ NPT die and attaching a ¼ NPT to 3/8 barb fitting to the turbo which worked perfectly.

Finally I hooked up all my boost piping and the vacuum for the turbo. The TDI fires right up, sounds great, but I have other issues I'm still trying to solve at this point. It's a project though and I'm just happy to still be moving forward with everything.

Here is the video if you want to watch:

Thanks

Grant

I got my new GT1752v turbo in and installed into my BEW TDI swapped TJ Wrangler. The turbo bolted up and fit perfectly. Once the turbo was in place I went about getting it all plumbed for exhaust, oil, vacuum and intercooler piping. Though in getting the pictures ready for this post I realized I forgot to take pictures of the new turbo before I installed it.

It would have been really nice to run a newer style turbo on my swap but at this point, almost 4 years into this build, I'm just wanting my TJ back on the road and more importantly back on the trails. The GT1752v was quite literally a bolt on, there were no issues getting it installed at all.

Next I turned my attention to making a downpipe for the turbo to connect up to the rest of my exhaust system. I had gotten a flange made from KubotaSwappers so that I could fabricate a downpipe that would connect to the back of my turbo. I was planning on using my plasma cutting table to make one myself but my plasma cutter is not working at the moment.

With the exhaust all figured out, I then went about figuring out how to hook up the oiling system for the turbo. I had ordered a kit so that I could put together my own oil return line from the turbo to the TDI block. However the placement of my motor mounts interfered with the supplied fitting for the turbo. I ended up modifying the original return line by using a ¼ NPT die and attaching a ¼ NPT to 3/8 barb fitting to the turbo which worked perfectly.

Finally I hooked up all my boost piping and the vacuum for the turbo. The TDI fires right up, sounds great, but I have other issues I'm still trying to solve at this point. It's a project though and I'm just happy to still be moving forward with everything.

Here is the video if you want to watch:

Thanks

Grant