You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Picking up where I left off

- Thread starter Chris

- Start date

- Status

- Not open for further replies.

Have you looked in the frame yet? Probably nothing, but 1 year there you never know.

View attachment 231402

Not yet, but I'm sure Blaine can take a look (or I can when I get it back).

Looks like it needs a frame swap and some safety caps for good measure.Have you looked in the frame yet? Probably nothing, but 1 year there you never know.

View attachment 231402

Maybe Blaine can use the plasma cutter to make a window into the frame. Once he's done using it to shorten the front shocks that is.

Looks like it needs a frame swap and some safety caps for good measure.

Maybe Blaine can use the plasma cutter to make a window into the frame. Once he's done using it to shorten the front shocks that is.

UKTJ

TJ Addict

I’m not really sure what is actually be done to Chris’ Jeep and would not ask anyone to explain (recent evidence suggests it would take a very long time), but I am enjoying the journey and the beating up on Chris by those that do understand. However, I am back to wondering whether it would be easier to start from a parts catalogue and just build something from scratch rather than gradually removing every part of the original TJ one-by-one.

I am back to wondering whether it would be easier to start from a parts catalogue and just build something from scratch rather than gradually removing every part of the original TJ one-by-one.

Depends, some of those purpose built rock crawler buggies can exceed 100k pretty quickly.

One year in Masshole, I would think about getting it crushed. What is the going rate for junk medal in AZ?

There are a handful of guys that would powdercoat axles for rigs here in AZ - all of them stopped once people realize how terrible of an idea that is. Everyone I know that's powdercoated a rig that they actually use has said it's a waste of time and $$...I am going to remove the axles at some point in the near future and have them blasted and powder coated. My OCD will not allow this.

Clean the rust, use some rust converting spray where needed, then something like Steel-IT or VHT Epoxy paint (my favorite). Both are quite durable and easy to touch up. With our lack of salt and dry weather, it will never cause another issue.

You are aware that I cut a large hole in the frame to stick that shock tower in there, right? And, that was done after I hacked off the rear section to raise it. If there was any rust present whatsoever in those sections, you would have a phone call, email, message on here and pictures of same.Not yet, but I'm sure Blaine can take a look (or I can when I get it back).

Got it! In that case I’ll just plan on stripping them down and going OCD crazy with cleaning them before paint.There are a handful of guys that would powdercoat axles for rigs here in AZ - all of them stopped once people realize how terrible of an idea that is. Everyone I know that's powdercoated a rig that they actually use has said it's a waste of time and $$...

Clean the rust, use some rust converting spray where needed, then something like Steel-IT or VHT Epoxy paint (my favorite). Both are quite durable and easy to touch up. With our lack of salt and dry weather, it will never cause another issue.

Makes my life somewhat easier too.

You are aware that I cut a large hole in the frame to stick that shock tower in there, right? And, that was done after I hacked off the rear section to raise it. If there was any rust present whatsoever in those sections, you would have a phone call, email, message on here and pictures of same.

That’s right!

What is being done is not atypical. Shocks are being moved to relocated mounts to afford longer shocks with balanced travel. Rear bumper crossmember was moved up 1.25" to improve departure angle and hide the gap between the top of frame and bottom of rear tub area under the tailgate that is produced when a body lift is installed. (Chris thinks he is being sly by requesting the departure improvement, reality is there wasn't a problem there, he really wanted the butt crack to disappear)I’m not really sure what is actually be done to Chris’ Jeep and would not ask anyone to explain (recent evidence suggests it would take a very long time), but I am enjoying the journey and the beating up on Chris by those that do understand. However, I am back to wondering whether it would be easier to start from a parts catalogue and just build something from scratch rather than gradually removing every part of the original TJ one-by-one.

I was going to make a joke about Black Don't Crack, but @Chris is whiter than Wonder Bread!What is being done is not atypical. Shocks are being moved to relocated mounts to afford longer shocks with balanced travel. Rear bumper crossmember was moved up 1.25" to improve departure angle and hide the gap between the top of frame and bottom of rear tub area under the tailgate that is produced when a body lift is installed. (Chris thinks he is being sly by requesting the departure improvement, reality is there wasn't a problem there, he really wanted the butt crack to disappear)

I could really care less about the crack. They make bumpers that cover the crack if that’s all I was after.

Moreover I just want it done while I am there, because with some of the stuff I'm getting into out here I simply feel that extra ground clearance isn't going to hurt, even if I don't use it.

Moreover I just want it done while I am there, because with some of the stuff I'm getting into out here I simply feel that extra ground clearance isn't going to hurt, even if I don't use it.

Man, Blaine's work looks way better than it did leaving the factory. Even the new robots on the assembly line don't weld that good.

I was thinking the same thing. Might have to consider moving closer to that area so can have him work on my LJ. Well that and take advantage of wheeling without Missouri mud.

Yeah, ask the 2018 JL owners how they like those factory weldsMan, Blaine's work looks way better than it did leaving the factory. Even the new robots on the assembly line don't weld that good.

Regardless of what is or isn't good on other models, the TJs for all of their "bad" appearances in the weld department really have very few failures. If you really want to understand welds, welding, and what a good weld can do regardless of appearance, take a look at the front spring/shock mounts at the frame. The entire weight of the rig is on those little tiny welds along the bottom and that force is multiplied many times over when you stuff the front at speed yet no one has ever managed to make them fail.Yeah, ask the 2018 JL owners how they like those factory welds

My welds are many times over what is actually required to hold something in place and that is because I, like most amateurs, way over do it because we don't weld enough to actually be good at it.

More photos of the progress from Blaine.

Raised body mounts:

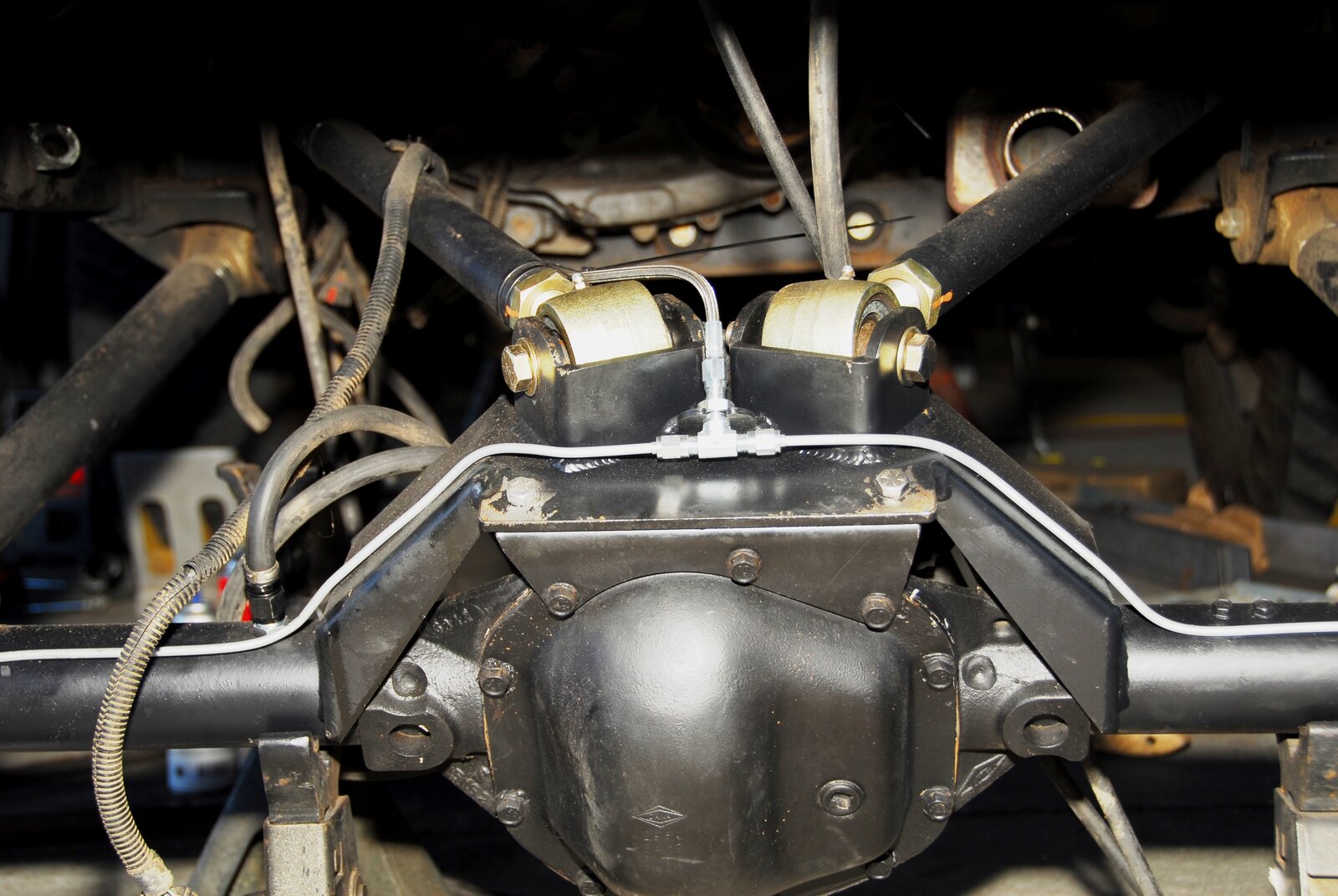

Rear Antirock:

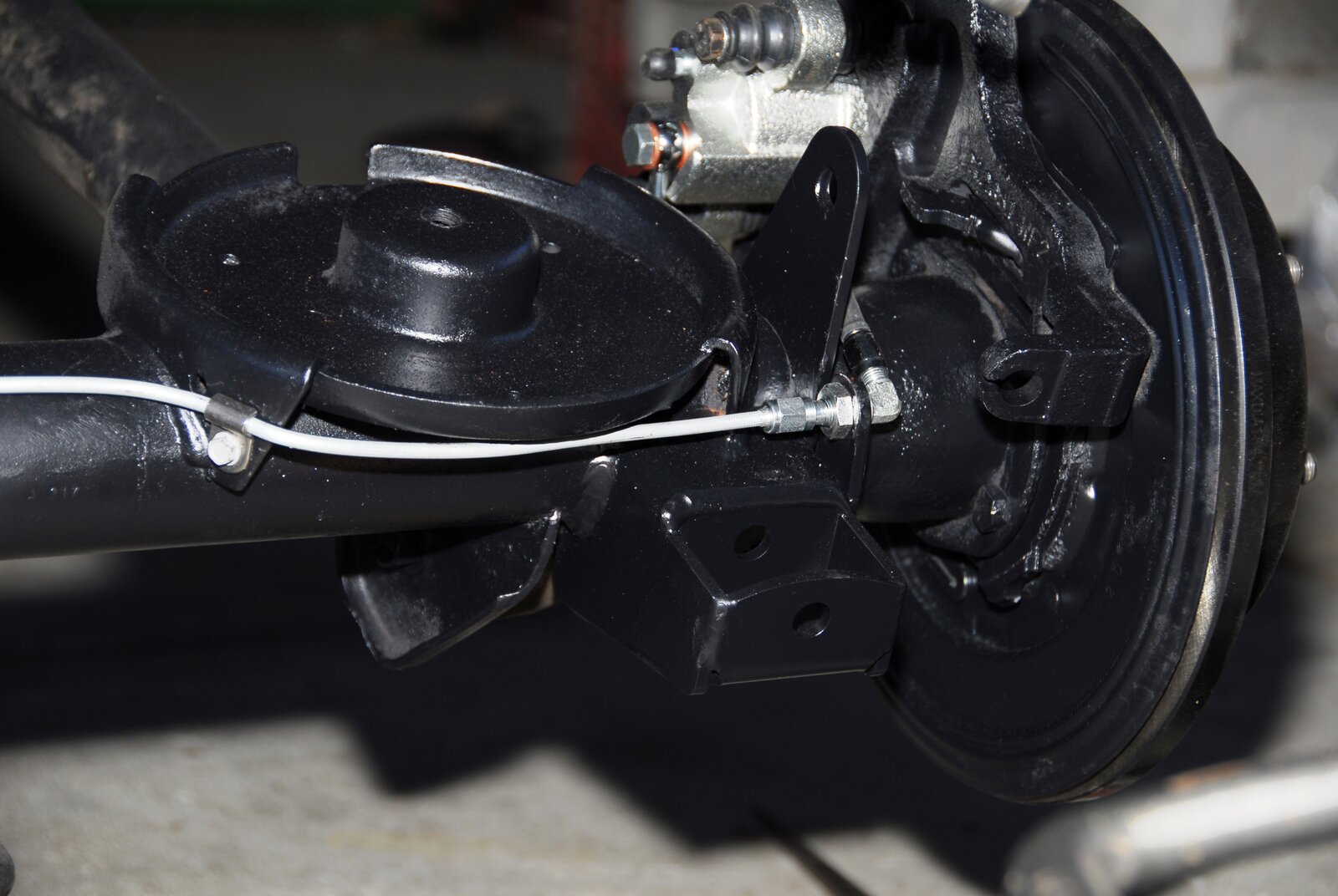

Wizard brake flip, new rotors, new calipers, and custom brake lines:

Raised body mounts:

Rear Antirock:

Wizard brake flip, new rotors, new calipers, and custom brake lines:

- Status

- Not open for further replies.