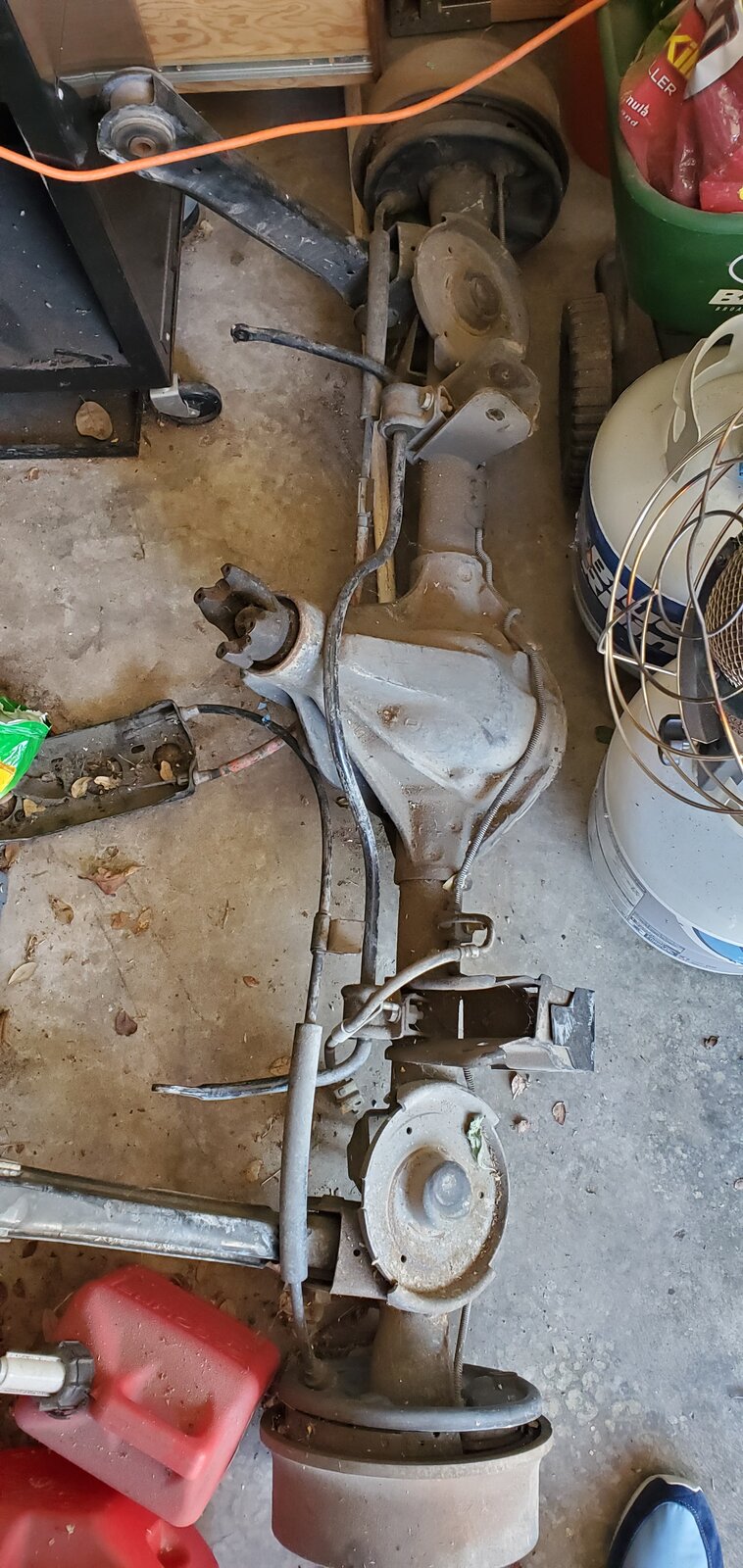

I have a Dana 44 that I'll be swapping into the rear of my 2004. I am going to degrease, sand (3M bristle discs on an angle grinder), self etching primer, then rattle can for easy touch ups.

But, what are my steps in prepping for everything else? Here are the other items that will be addressed before, during, or after install:

New rear shoes/springs

Locker

Regear

What should/can be done with the axle on stands versus on the Jeep?

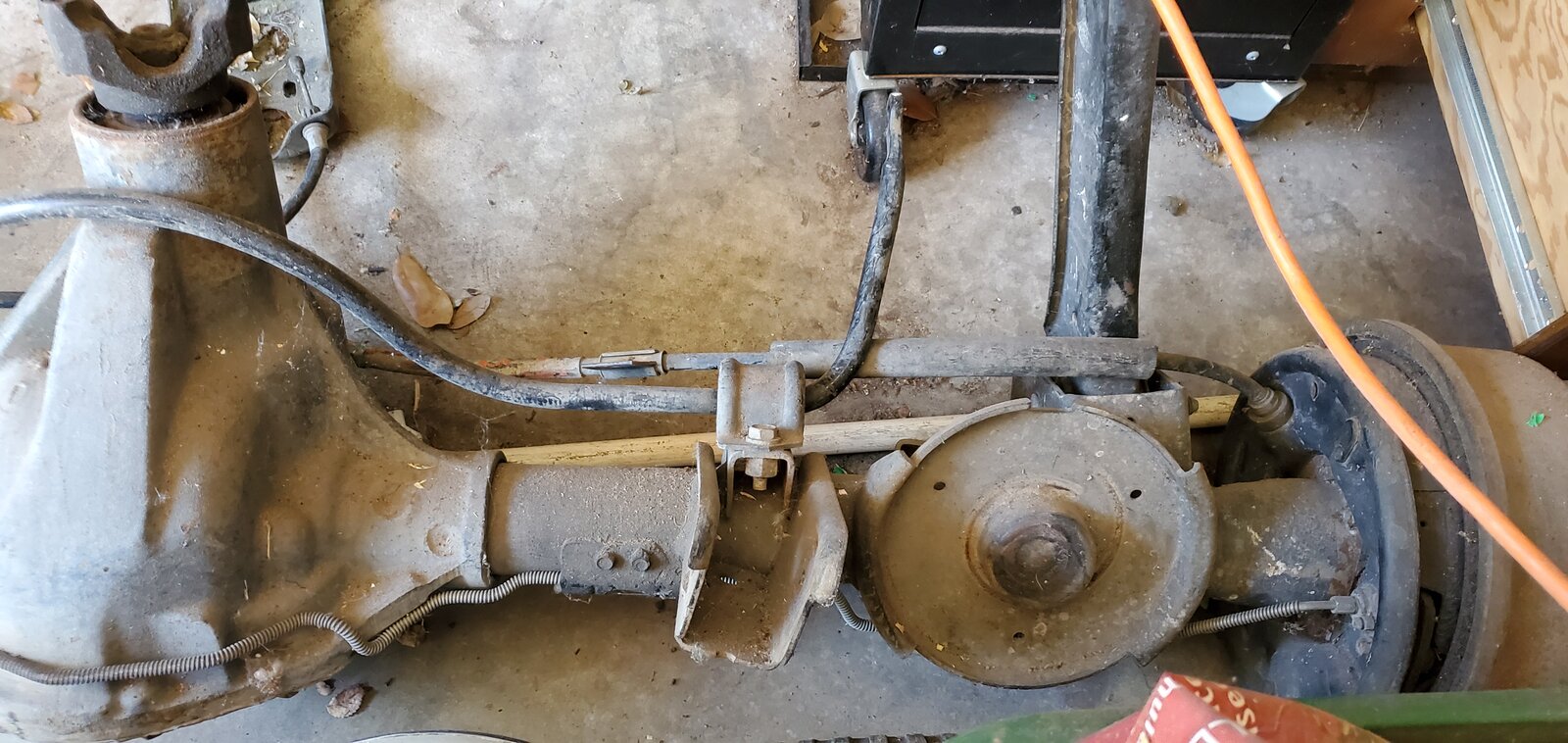

Also, does that driver's side upper control arm mount look bent?

But, what are my steps in prepping for everything else? Here are the other items that will be addressed before, during, or after install:

New rear shoes/springs

Locker

Regear

What should/can be done with the axle on stands versus on the Jeep?

Also, does that driver's side upper control arm mount look bent?