It's too bad you weren't able to get the 6R80 to work well in your Jeep. I absolutely love mine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a diesel powered RHD TJ Wrangler (Picture Heavy)

- Thread starter RustyAutoholicGuy

- Start date

It's too bad you weren't able to get the 6R80 to work well in your Jeep. I absolutely love mine.

I've been offered a chance to go back to the 6r80 with a different adapter AND a different controller. The challenge for me there is I can't run my Rubicon transfer case with the 6r80 because I can't get the correct input shaft for the transfer case. I'll be honestly, it's so tempting to switch back, the 6-speed is awesome, and I think it would really work well too . . . it's something I'm still really considering at this point, I just don't know what transfer case I would pair with the transmission . . .

-Grant

Hey Tjers,

I finally have a diesel engine and automatic transmission that works in my TJ Wrangler. After all the different combinations I've experimented with over the years, 3 engines, 6 transmissions, 5 adapters, 2 transfer cases, 7 turbos, and a slew of other parts and pieces, I FINALLY have a combination that is working. I can not tell you how great it felt to take my TJ out onto the road and to be able to do highway speeds for the first time ever without having to worry about heat and to have my TJ just drive like a TJ again.

View attachment 476964

First I had to wrap up getting the wiring installed for the TDI ECU and the CompuShift ECU. While doing that I realized I had rushed installing my Autometer Gauges so I spent time redoing that work as well on my TJ Wrangler. If there is anything I have learned over the past 5 years is that I need to do things the correct way, not the quick way.

View attachment 476965

I need to give a huge thanks to HGM Electronics who make the CompuShift transmission controller I'm using. This build would have not been possible without their help and support. For reference to anyone who doesn't know. I'm running an AW4 transmission but I'm using the valvebody out of a 2007 Toyota Tacoma A340F in place of the AW4 valvebody. This was suggested by the people at CompuShift so I wouldn't have to figure out a way to connect the TV, Throttle Valve, Cable to control line pressure in the transmission. There are several other benefits to this approach as well, but the removal of the TV cable and allowing the CompuShift to control the line pressure is the main benefit. I ran into a few technical questions with this setup and the people at HGM Electronics were extremely responsive in getting this combination working with my TDI swap.

View attachment 476966

Onto the test drive. WOW just WOW. First I will say I ran into a few minor issues which is expected on something like this and they were all a result of things I had done. I forgot to cap off/cover one of the CompuShift wires so that it was grounding on my transmission causing the CompuShift to put my AW4 into 4th gear. I then didn't tighten a boost clamp all the way so it blew off and finally, I had to clear out the gunk in my cooling system. The gunk in the cooling system was a two-fold problem, one being I left the heater core exposed to the elements for years and secondly, I hadn't hooked up the coolant loop correctly the first time, so I ended up flushing the system twice before going on my second road test.

View attachment 477012

The road tests, I'm not sure what I can say other than it was WAY too cold to be driving my TJ with no top or doors in low 50° weather in November. Nothing overheated and both the engine and transmission acted exactly as I thought they should which was an amazing feeling. The BEW TDI engine with an engine tune from TekMekTronics for the GTD1752vrk turbo worked flawlessly and the CompuShift tune for the AW4 also worked flawlessly out of the box. As of this video, I have not touched the transmission at all. I would say the CompuShift is 90% perfect and would easily allow me to drive my TJ Wrangler wherever I want to.

View attachment 476967

I can say with 100% confidence that my TJ has not run and driven this well since it had the 4.0l engine and 42rle transmission in it from 2018. After my second road test, I started taking my TJ out for quick errands around town, that's how much confidence I have in my engine and transmission combination.

Now for what needs to be done next. Turns out there is quite a list. I have two major transmission leaks I'll need to investigate, though I know what one of them is already. I need to get my HVAC controls and heat working ASAP if I'm going to be driving this TJ at all this winter, also I need to re-install the hardtop and doors which I will be doing next. Lastly, it's all the minor things I haven't bothered to fix. It needs ball joints, tie rod ends, and I still need to figure out the brakes and steering because my power steering pump is still whinning once everything gets hot. But with all that said, it runs and drives and I couldn't be happier.

Here is the video if you'd like to watch:

Thank you for all the years of help and support with all the iterations of this build!

Grant

WOW I know that had to be a great feeling to finally get it out driving again. I know it's been a long haul for you but you are at the end now.

I've been offered a chance to go back to the 6r80 with a different adapter AND a different controller. The challenge for me there is I can't run my Rubicon transfer case with the 6r80 because I can't get the correct input shaft for the transfer case. I'll be honestly, it's so tempting to switch back, the 6-speed is awesome, and I think it would really work well too . . . it's something I'm still really considering at this point, I just don't know what transfer case I would pair with the transmission . . .

-Grant

Could you get the crawlbox with the correct spline for the 6r80 & then the 241? Do you have the room for it? Plus then you'd have the 2.72 & 4.1 gearing...

WOW I know that had to be a great feeling to finally get it out driving again. I know it's been a long haul for you but you are at the end now.

Could you get the crawlbox with the correct spline for the 6r80 & then the 241? Do you have the room for it? Plus then you'd have the 2.72 & 4.1 gearing...

It was a fantastic feeling! I can't put into words how good it felt, though all the other things I still have to fix are now obvious as well. I REALLY need to do ball joints and tie rods for my steering.

As for my 6r80, I'm debating going back to it and trying it again with what I have because then I don't need new driveshafts or anything else. Going with a NP231 would be the easiest setup, and I would just need to fabricate a new crossmember, at that point I could swap between the AW4/NVG241OR and 6r80/NP231 setup with changing much else.

It's really tempting to try it out to see if I can get it working this time around.

Thanks

Grant

It was a fantastic feeling! I can't put into words how good it felt, though all the other things I still have to fix are now obvious as well. I REALLY need to do ball joints and tie rods for my steering.

As for my 6r80, I'm debating going back to it and trying it again with what I have because then I don't need new driveshafts or anything else. Going with a NP231 would be the easiest setup, and I would just need to fabricate a new crossmember, at that point I could swap between the AW4/NVG241OR and 6r80/NP231 setup with changing much else.

It's really tempting to try it out to see if I can get it working this time around.

Thanks

Grant

The first step to dealing with addiction is admitting you have a problem. You're obviously one of those perpetual project guys like most us enablers!

In a whispering voice: Atlassss.

It just cost so much money . . . also I'm in this weird position where my driveshafts will work both setups, but yes . . Atlas is tempting . . .

The first step to dealing with addiction is admitting you have a problem. You're obviously one of those perpetual project guys like most us enablers!

You know, you're not wrong! I'm still weighing the pros and cons of this route.

I'm almost positive I need gear my axles regardless if I go back to the 6r80 or stay with my AW4, the questions is which gear ratios do I go with?

-Grant

Tire size?I'm almost positive I need gear my axles regardless if I go back to the 6r80 or stay with my AW4, the questions is which gear ratios do I go with?

-Grant

What do the torque and hp curves look like compared to the 4.0l? More or less torque?

My gut wants to say don't gear as deep as for gas.but isn't the tdi a high revver?

Tire size?

What do the torque and hp curves look like compared to the 4.0l? More or less torque?

My gut wants to say don't gear as deep as for gas.but isn't the tdi a high revver?

Because of the turbo and custom turbo tune setup, I'm not sure what the curve looks like but I know these engines like to cruise above 2000 rpm. I've got 31.8 tires and I've been messing around with this site: http://www.grimmjeeper.com/gears.html and it looks like 4.56 might work out great, 55mph in 4th is the only question there but it's right at 2000 rpm so it might be fine. I need to do some road testing to see how torque lock up affects rpm in both locked and unlocked positions at 55mph. I might need to look for a low stall speed torque converter first before I look into regearing.

-Grant

Last edited:

Hey TJers,

As with all swaps and builds, once you get some seat time on your project you start discovering problems or mistakes that were made during the build. In my case, I had some problems that went back years that I had solved by either replacing, rewiring, or even removing parts to get my TDI Swapped TJ Wrangler running correctly, and I still have a few minor things left to address!

First was a ground issue that I know I've been having for a while now. Turns out when I thought I had grounded the engine and the frame of my Wrangler, I had actually ground the engine and the engine. I put one of my ground wires to the top of the motor mount plate which rested on a hydraulic motor mount. Easy enough to figure out, just moved that ground wire to the bottom of the motor mount which then gave me a grounded frame. I was still having some weird issues with my gauges and even my transmission solenoids however when I turned on my HVAC blower fan. Turns out that at some point in the past 5 years, I put a ground wire to the mounting stud for the blower fan. Changing that ground solved all my issues there.

I then went to address my AW4 transmission leaks. I had two, one was from where the TV cable used to be, and the second I thought was a bad rear main seal on the backside of the transmission where the transfer case bolts to the transmission. Turns out you can not use a clocking ring on a NVG241OR transfercase because the input shaft for that transfer case is so short. Removing the clocking ring rotated the Rubicon transfer case higher which gave me more ground clearance but was making contact with the body. SO I did what any sensible person does, and I took a 2.5lb hammer to make a little bit of extra clearance on the tub of my Wrangler.

While doing all of this, I tried a quick fix to the hole for the TV Cable in my transmission case but ended up dropping a rubber stopper into the transmission pan. This ended up being a major blessing because when I removed the transmission pan I found one of my valvebody bolts in the bottom of the pan. I then inspected the rest of the bolts and found that most of the bolts were loose. So I removed each bolt, cleared out the hole the bolt went into with compressed air and then applied blue Loctite to the threads before retorquing the bolts back into place.

During the test drive to make sure the transmission was no longer leaking and that my grounds were still working as they should, my power steering system which supplies pressure for both my steering and my hydroboost brakes started getting louder and louder. I decided to go back to the factory brake booster on my TJ because my BEW TDI has a vacuum pump on the back of the cylinder header that would make enough vacuum for the braking system to work properly and I could go back to a VW power steering pump to supply pressure for my power steering box. I did go with a VR6 pump just because it's slightly higher pressure and the closest to the factory TJ power steering pump as well.

With the power steering and braking system working correctly, I started driving my TJ more and discovered that under heavy acceleration my front driveshaft was contacting the tub of my TJ Wrangler from where I had removed the clocking ring on my Rubicon Transfer case. In a little bit of irony, I realized looking at it, I had 3 placements for the mounting bolt with the heavy-duty AW4 transmission mount I had bought and was able to push the transmission closer to my driver's side underneath my TJ. Maybe I didn't need to do the clearancing with sledge hammer but I have more room now so still a win. But by moving the transmission and transfer case over I now created a bind with my front hydraulic motor mounts. I removed my driver's side motor mount plate and redrilled the hole so that the engine, transmission, and transfer case are all now sitting in a neutral position in my TJ with no bind.

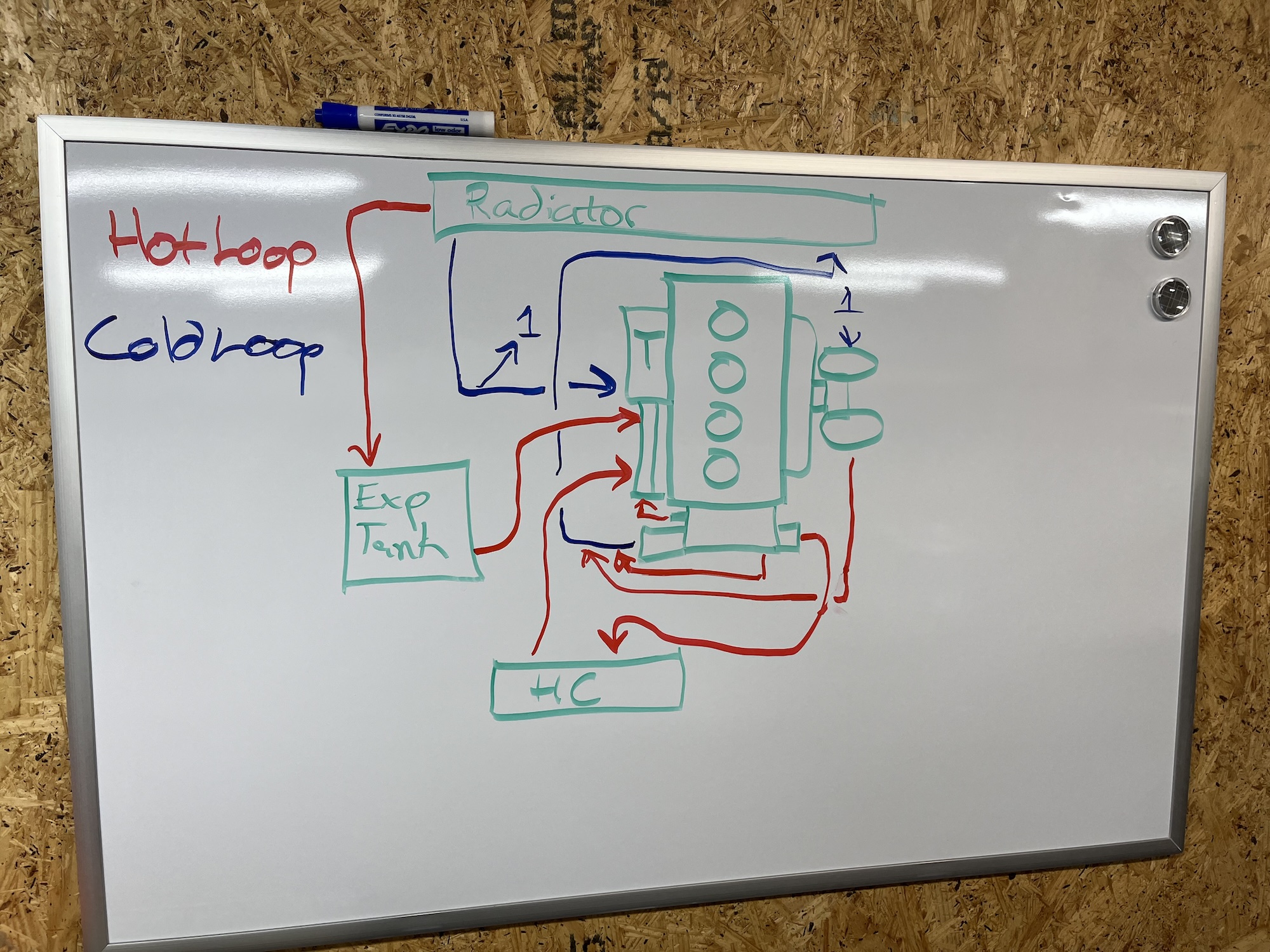

And now we get to the cooling system. I started with my cooling system running too cold. My engine barely got to 150° and my transmission was never getting over 125°. For the transmission, the solution was to remove the Ford 6r80 transmission cooler and just run the factory transmission cooler that is in my factory radiator. The cooling system became an almost 3-week long saga of re-routing hoses and trying different thermostats until I drew up, poorly I might add, how the coolant flows in my cooling system. I go in-depth about the cooling in my video so I won't do that here.

However during that I found a mistake I made earlier this year that I can't believe I hadn't caught sooner. I crushed the coolant temperature sensor wiring harness between the AW4 transmission and the adapter plate bolted to the back of my engine. This means my ECU was not seeing an accurate temperature for my coolant. Have I ever checked for an error code on my ECU . . . nope, but I will start doing that regularly going forward.

However during that I found a mistake I made earlier this year that I can't believe I hadn't caught sooner. I crushed the coolant temperature sensor wiring harness between the AW4 transmission and the adapter plate bolted to the back of my engine. This means my ECU was not seeing an accurate temperature for my coolant. Have I ever checked for an error code on my ECU . . . nope, but I will start doing that regularly going forward.

With all those changes and updates made, I was able to put almost 75 miles on my TJ yesterday with no issues. I am going to swap out the thermostat from the 192° to a 180° because I don't like how hot everything is running and I want to see if I can bring down my temperatures a little more but for the moment everything is working as it should I can continue to put the rest of my TJ back together.

Here is the video if you'd like to watch:

Thanks

Grant

As with all swaps and builds, once you get some seat time on your project you start discovering problems or mistakes that were made during the build. In my case, I had some problems that went back years that I had solved by either replacing, rewiring, or even removing parts to get my TDI Swapped TJ Wrangler running correctly, and I still have a few minor things left to address!

First was a ground issue that I know I've been having for a while now. Turns out when I thought I had grounded the engine and the frame of my Wrangler, I had actually ground the engine and the engine. I put one of my ground wires to the top of the motor mount plate which rested on a hydraulic motor mount. Easy enough to figure out, just moved that ground wire to the bottom of the motor mount which then gave me a grounded frame. I was still having some weird issues with my gauges and even my transmission solenoids however when I turned on my HVAC blower fan. Turns out that at some point in the past 5 years, I put a ground wire to the mounting stud for the blower fan. Changing that ground solved all my issues there.

I then went to address my AW4 transmission leaks. I had two, one was from where the TV cable used to be, and the second I thought was a bad rear main seal on the backside of the transmission where the transfer case bolts to the transmission. Turns out you can not use a clocking ring on a NVG241OR transfercase because the input shaft for that transfer case is so short. Removing the clocking ring rotated the Rubicon transfer case higher which gave me more ground clearance but was making contact with the body. SO I did what any sensible person does, and I took a 2.5lb hammer to make a little bit of extra clearance on the tub of my Wrangler.

While doing all of this, I tried a quick fix to the hole for the TV Cable in my transmission case but ended up dropping a rubber stopper into the transmission pan. This ended up being a major blessing because when I removed the transmission pan I found one of my valvebody bolts in the bottom of the pan. I then inspected the rest of the bolts and found that most of the bolts were loose. So I removed each bolt, cleared out the hole the bolt went into with compressed air and then applied blue Loctite to the threads before retorquing the bolts back into place.

During the test drive to make sure the transmission was no longer leaking and that my grounds were still working as they should, my power steering system which supplies pressure for both my steering and my hydroboost brakes started getting louder and louder. I decided to go back to the factory brake booster on my TJ because my BEW TDI has a vacuum pump on the back of the cylinder header that would make enough vacuum for the braking system to work properly and I could go back to a VW power steering pump to supply pressure for my power steering box. I did go with a VR6 pump just because it's slightly higher pressure and the closest to the factory TJ power steering pump as well.

With the power steering and braking system working correctly, I started driving my TJ more and discovered that under heavy acceleration my front driveshaft was contacting the tub of my TJ Wrangler from where I had removed the clocking ring on my Rubicon Transfer case. In a little bit of irony, I realized looking at it, I had 3 placements for the mounting bolt with the heavy-duty AW4 transmission mount I had bought and was able to push the transmission closer to my driver's side underneath my TJ. Maybe I didn't need to do the clearancing with sledge hammer but I have more room now so still a win. But by moving the transmission and transfer case over I now created a bind with my front hydraulic motor mounts. I removed my driver's side motor mount plate and redrilled the hole so that the engine, transmission, and transfer case are all now sitting in a neutral position in my TJ with no bind.

And now we get to the cooling system. I started with my cooling system running too cold. My engine barely got to 150° and my transmission was never getting over 125°. For the transmission, the solution was to remove the Ford 6r80 transmission cooler and just run the factory transmission cooler that is in my factory radiator. The cooling system became an almost 3-week long saga of re-routing hoses and trying different thermostats until I drew up, poorly I might add, how the coolant flows in my cooling system. I go in-depth about the cooling in my video so I won't do that here.

With all those changes and updates made, I was able to put almost 75 miles on my TJ yesterday with no issues. I am going to swap out the thermostat from the 192° to a 180° because I don't like how hot everything is running and I want to see if I can bring down my temperatures a little more but for the moment everything is working as it should I can continue to put the rest of my TJ back together.

Here is the video if you'd like to watch:

Thanks

Grant