You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rock Sliders / Rocker Guards Guide

- Thread starter JMT

- Start date

I sure didn't see that coming. That isn't even 1/8".I'm wondering if ARB uses 1 7/8 .120 wall erw. Seems more likely than 1.5 sch 40.

I don't have an easy way to weigh them, but the base isn't very thick.

View attachment 300200

View attachment 300201

View attachment 300202

UKTJ

TJ Addict

Sorry that should have said some are saying the ARBs are 1/8” rather than 3/16”. Was not suggesting they could be 1/16”.Can't be the thinner at the listed weights.

If I was confident I could get a Savvy set before spring, I'd pull them and toss them on a scale. The bend on the top edge does help the rigidity a little, but a solid hit on the bottom will dent them pretty easily. I'm wondering if that tube is actually .065 wall.

I don't think I was that hard on them. My Jeep still has a 27 spline Dana 30 and a Dana 35 and all of that was done at a crawl.

I don't think I was that hard on them. My Jeep still has a 27 spline Dana 30 and a Dana 35 and all of that was done at a crawl.

Fishbone Sliders use the 3 body mounts on each side. This can result in undue stress on the body mounts.I went with the Fishbone step sliders. 2"x.120 tube and 3/16" steel plate. Banged them onthe rocks and have no issues yet.

Yeah, but the good news is with as crappy of a mounting system as that is, it makes it very hard to tear up the tube step.Fishbone Sliders use the 3 body mounts on each side. This can result in undue stress on the body mounts.

UKTJ

TJ Addict

Everyone needs to make their own choice based on what is important to them. But for me it seems there are a number of factors: some absolute, some modifiable and some more fixed. This then has to be looked at on a cost benefit basis by each person. I do not think anyone has added much to the points to consider that @mrblaine put forward early in the thread, so those are thebasis for my consideration.

The points that I am tending to consider as 'absolutes' are 1. the robustness of the material the sliders are made from, and 2. the way they mount under the Jeep. So, if a slider is made of weak materials that will not last and may not do the job they are intended to do then I would not consider them. Similarly, if a slider is frame mounted, from what I read it could end up doing at least as much damage as it prevents, so that one is off the list.

Considerations that I would categorise as modifiable include the number of fixing points and the existence or otherwise of some sort of backing plate. More holes can be drilled in the slider and the tube and a couple of pieces of suitably reobust aluminium secured to act as a backer plate. So for me those factors do not strongly influence any decision.

Other considerations that are harder to modify (though that may vary for individuals) include the shape of the transition from covering the side to covering the bottom of the Jeep, the length of coverage (i.e. are the sliders WW2WW), modular replaceability and weight.

For me it is those third group that need to get considered against the cost of each option.

The points that I am tending to consider as 'absolutes' are 1. the robustness of the material the sliders are made from, and 2. the way they mount under the Jeep. So, if a slider is made of weak materials that will not last and may not do the job they are intended to do then I would not consider them. Similarly, if a slider is frame mounted, from what I read it could end up doing at least as much damage as it prevents, so that one is off the list.

Considerations that I would categorise as modifiable include the number of fixing points and the existence or otherwise of some sort of backing plate. More holes can be drilled in the slider and the tube and a couple of pieces of suitably reobust aluminium secured to act as a backer plate. So for me those factors do not strongly influence any decision.

Other considerations that are harder to modify (though that may vary for individuals) include the shape of the transition from covering the side to covering the bottom of the Jeep, the length of coverage (i.e. are the sliders WW2WW), modular replaceability and weight.

For me it is those third group that need to get considered against the cost of each option.

I agree except for the ww2ww. I think that is more important.Everyone needs to make their own choice based on what is important to them. But for me it seems there are a number of factors: some absolute, some modifiable and some more fixed. This then has to be looked at on a cost benefit basis by each person. I do not think anyone has added much to the points to consider that @mrblaine put forward early in the thread, so those are thebasis for my consideration.

The points that I am tending to consider as 'absolutes' are 1. the robustness of the material the sliders are made from, and 2. the way they mount under the Jeep. So, if a slider is made of weak materials that will not last and may not do the job they are intended to do then I would not consider them. Similarly, if a slider is frame mounted, from what I read it could end up doing at least as much damage as it prevents, so that one is off the list.

Considerations that I would categorise as modifiable include the number of fixing points and the existence or otherwise of some sort of backing plate. More holes can be drilled in the slider and the tube and a couple of pieces of suitably reobust aluminium secured to act as a backer plate. So for me those factors do not strongly influence any decision.

Other considerations that are harder to modify (though that may vary for individuals) include the shape of the transition from covering the side to covering the bottom of the Jeep, the length of coverage (i.e. are the sliders WW2WW), modular replaceability and weight.

For me it is those third group that need to get considered against the cost of each option.

UKTJ

TJ Addict

If you add WW2WW to the mandatory list it significantly reduces choice. As far as I can see it is a choice between Savvy and GenRight Mini Boat Sides, and if you are going either of those routes they do not come cheaply, even in the US. Barnes 4WD do a WW2WW inexpensive option, bit it is attached to the body mounts which I guess counts it out.I agree except for the ww2ww. I think that is more important.

I had a go at trying to update your original summary into a more simplified, tabular form. I have only done this for a few of the options and there are a few gaps still...

| Savvy | ARB | Warn | Poison Spyder | Barnes 4WD | RT Offroad | GenRight Mini Boat Sides | |||||||

| Rocker Guard Material | ?/?" Aluminium | 1/8" Steel | 3/16" Steel | 3/16" Steel | 3/16" Steel | 3/16" Steel | 3/16" Steel | ||||||

| Underside Fixings | Bolts | Bolts | Spacers & Bolts | Body Mounts | Body Mounts | Spacers & Bolts | Bolts | ||||||

| Step / Slider | Y | Y | N | Y | N | Y | Y | ||||||

| Step / Slider Material | 3/16" Steel | 1 1/4 Sch 40 | n/a | ? DOM | 3/16" Steel | 3/16" Steel | 1 3/4 .120" DOM | ||||||

| Backer System | Y | Y | N | N | N | N | $39 option | ||||||

| WW2WW | Y | N | N | N | Y | N | Y (req's trim) | ||||||

| Underside Shape / Transition | Double Bend | Double Bend | Curved | Single Bend | Single Bend | Single Bend | Double Bend | ||||||

| Weight | c.69lbs | c.65lbs | ? | c.74lbs | ? | c.65lbs | ? | ||||||

| Domestic US Cost (ex. Shipping) | $700 | $415 | $415 | $502 | $250 | $170 | $800 |

I have used Quadratec prices where they sell them, and the manufacturer's price where not. It seems in the three years since your original post costs have risen quite a lot in some cases.

As ever, the choice for me is different due to the cost of shipping. GenRight won't quote online to ship to the UK, but I did look at Savvy in the past and the cost delivered to me, incl. import taxes, came out at just short of $1900.

In the UK, as far as I can see, I can only buy ARBs, Poison Spyder or RT Offroad. The Poison Spyders are out due to body mounting, but out of interest they cost over $1700 in the UK. The ARBs (questions pending on robustness of materials) are just under $750. The RT Offroad option is available for about $260.

My thinking is therefore to get the RT Offroad and buy some aluminium to use as a backer plate as suggested further up this thread by Jerry. With the cost saving versus the only two viable WW2WW options I am pretty sure I could find somebody to weld a small extension piece on each end, but to be honest I will probably just live with the risk as the terrain here is typically not charaterised by big rocks.

Wow! I get it. Those costs are insane. You’ll make it work. You at least know what you’re looking at and why and are choosing what will work for you within reason. Nice chart. I’ve thought about removing prices since they obviously change.If you add WW2WW to the mandatory list it significantly reduces choice. As far as I can see it is a choice between Savvy and GenRight Mini Boat Sides, and if you are going either of those routes they do not come cheaply, even in the US. Barnes 4WD do a WW2WW inexpensive option, bit it is attached to the body mounts which I guess counts it out.

I had a go at trying to update your original summary into a more simplified, tabular form. I have only done this for a few of the options and there are a few gaps still...

Savvy ARB Warn Poison Spyder Barnes 4WD RT Offroad GenRight Mini Boat Sides Rocker Guard Material ?/?" Aluminium 1/8" Steel 3/16" Steel 3/16" Steel 3/16" Steel 3/16" Steel 3/16" Steel Underside Fixings Bolts Bolts Spacers & Bolts Body Mounts Body Mounts Spacers & Bolts Bolts Step / Slider Y Y N Y N Y Y Step / Slider Material 3/16" Steel 1 1/4 Sch 40 n/a ? DOM 3/16" Steel 3/16" Steel 1 3/4 .120" DOM Backer System Y Y N N N N $39 option WW2WW Y N N N Y N Y (req's trim) Underside Shape / Transition Double Bend Double Bend Curved Single Bend Single Bend Single Bend Double Bend Weight c.69lbs c.65lbs ? c.74lbs ? c.65lbs ? Domestic US Cost (ex. Shipping) $700 $415 $415 $502 $250 $170 $800

I have used Quadratec prices where they sell them, and the manufacturer's price where not. It seems in the three years since your original post costs have risen quite a lot in some cases.

As ever, the choice for me is different due to the cost of shipping. GenRight won't quote online to ship to the UK, but I did look at Savvy in the past and the cost delivered to me, incl. import taxes, came out at just short of $1900.

In the UK, as far as I can see, I can only buy ARBs, Poison Spyder or RT Offroad. The Poison Spyders are out due to body mounting, but out of interest they cost over $1700 in the UK. The ARBs (questions pending on robustness of materials) are just under $750. The RT Offroad option is available for about $260.

My thinking is therefore to get the RT Offroad and buy some aluminium to use as a backer plate as suggested further up this thread by Jerry. With the cost saving versus the only two viable WW2WW options I am pretty sure I could find somebody to weld a small extension piece on each end, but to be honest I will probably just live with the risk as the terrain here is typically not charaterised by big rocks.

Yeti08

Member

thats a nice spreadsheet.

the price jump is a big factor for me, Unfortunately I cant justify the top of the line pricing for savvy/genright. which leads me to consider ARB/warn, and I cannot find a clear better choice....

does anyone know if AtoZ is back open?

the price jump is a big factor for me, Unfortunately I cant justify the top of the line pricing for savvy/genright. which leads me to consider ARB/warn, and I cannot find a clear better choice....

does anyone know if AtoZ is back open?

UKTJ

TJ Addict

Personally, unless the ARBs are shown to be more than 1/8" I can't see how they can be a good choice. If you end up at Warn I would ask what about them justifies being 2.5x the cost of the RT Offroad?thats a nice spreadsheet.

the price jump is a big factor for me, Unfortunately I cant justify the top of the line pricing for savvy/genright. which leads me to consider ARB/warn, and I cannot find a clear better choice....

does anyone know if AtoZ is back open?

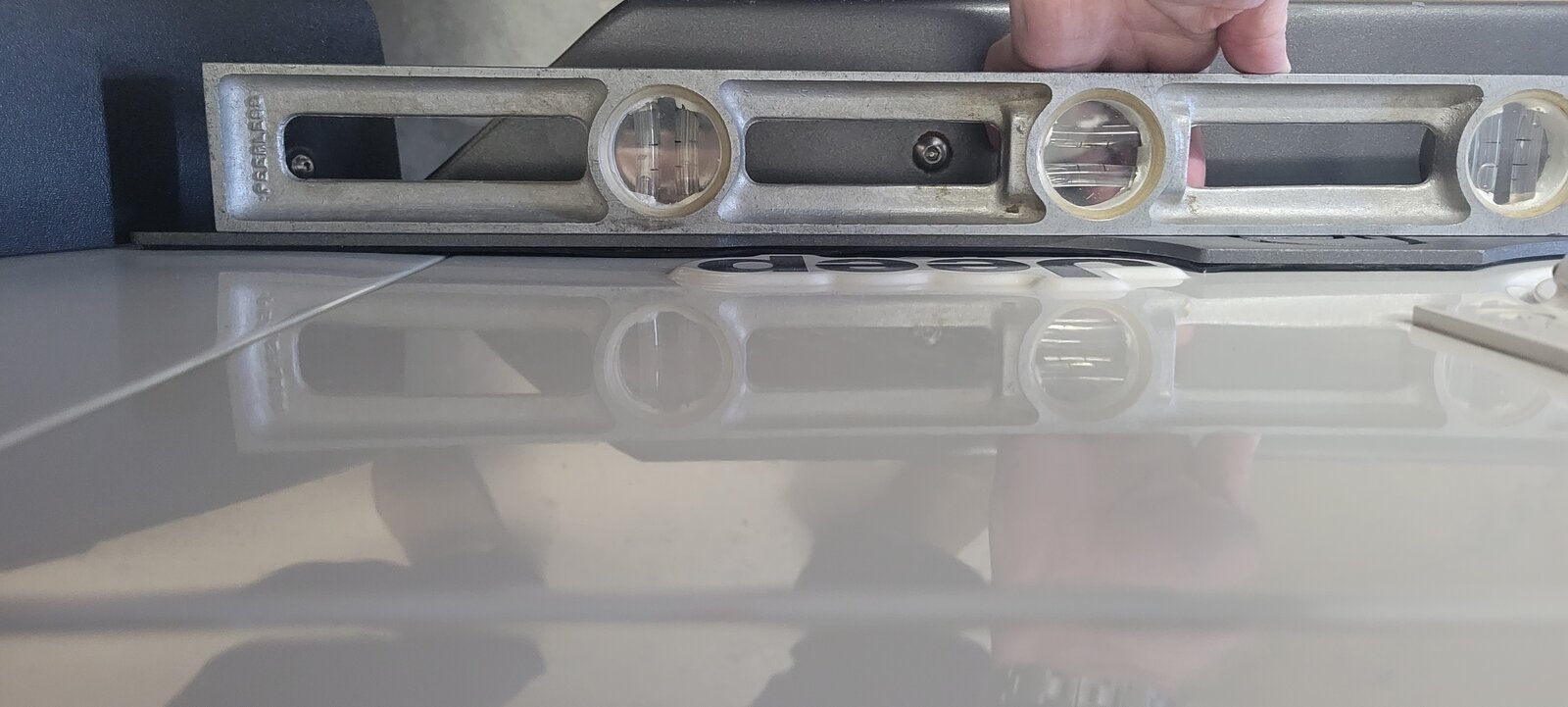

Anyone have an issue where the tub and slider have a small gap? Slider plate is straight so it seems the tub and fender are off just a bit. You can see the fender is being pulled out some. Level says the slider is straight. Only on the passenger side. No creases in the tub or damage. I went with jcr sliders a year ago because they were only $485 and savvy was out of stock. It looks like these are $720 now. Given the choice again I would go with savvy for the additional fasteners.

It looks like jcr could stand to benefit from a nutsert near the jeep logo. Another item I wish I had done was not follow jcr instructions to drill through the floor and just installed nutserts in the torque box.

I don't think these are a terrible option but I would install them a but differently, following a savvy slider install approach. I did preload these before installing like recommended on this site. I added some backing plates but in plan on adding a genright style backing plate with a piece of 3/16 angle to stretch across all the under door bolts. It has also cracked the factory seam sealer but the metal/spot welds are still intact under closer inspection.

It looks like jcr could stand to benefit from a nutsert near the jeep logo. Another item I wish I had done was not follow jcr instructions to drill through the floor and just installed nutserts in the torque box.

I don't think these are a terrible option but I would install them a but differently, following a savvy slider install approach. I did preload these before installing like recommended on this site. I added some backing plates but in plan on adding a genright style backing plate with a piece of 3/16 angle to stretch across all the under door bolts. It has also cracked the factory seam sealer but the metal/spot welds are still intact under closer inspection.

Last edited:

How do you know the tub is straight behind the JCR backing plate? Are you sure you pre-loaded the backing plate so it was flush with the tub before you drilled your holes and bolted it up? Was it flush a year ago but not now?Anyone have an issue where the tub and slider have a small gap? Slider plate is straight so it seems the tub and fender are off just a bit. You can see the fender is being pulled out some. Level says the slider is straight. Only on the passenger side. No creases in the tub or damage. I went with jcr sliders a year ago because they were only $485 and savvy was out of stock. It looks like these are $720 now. Given the choice again I would go with savvy for the additional fasteners.

View attachment 306429

View attachment 306430

View attachment 306431

View attachment 306432

It looks like jcr could stand to benefit from a nutsert near the jeep logo. Another item I wish I had done was not follow jcr instructions to drill through the floor and just installed nutserts in the torque box.

I don't think these are a terrible option but I would install them a but differently, following a savvy slider install approach. I did preload these before installing like recommended on this site. I added some backing plates but in plan on adding a genright style backing plate with a piece of 3/16 angle to stretch across all the under door bolts. It has also cracked the factory seam sealer but the metal/spot welds are still intact under closer inspection.

View attachment 306436

How do you know the tub is straight behind the JCR backing plate? Are you sure you pre-loaded the backing plate so it was flush with the tub before you drilled your holes and bolted it up? Was it flush a year ago but not now?

I followed your thread to be honest and your build is a big reason I ended up with these and the epdm rubber backing. It's been this way since install and hasn't gotten worse. I haven't contacted any thing really hard on that side though. More noticeable now because I swapped some stock fenders on so thinner sheet metal. My jeep had some thicker homemade fenders when I bought it. I had to move those inward quite a bit for it to sit closer to flush. That is likely part of the issue. I have read not all tubs are exactly the same.

It seems the tub is angled in slightly where it meets the fender. I have the fender pushed inward but could probably move it in a bit more. The backing plate just pulls the fender sheet metal out.

I bolted the backing plate to the slider preloaded everything from underneath, then made my holes with the backing plate clamped to the tub with quickclamps. I have had it off and on quite a bit because it's always bugged me.

I also don't like their stupid logo lol and asked for without but never got a response.

I plan on pulling them off once it warms up so wanted to see if anyone was having a similar issue.

I haven't seen this issue. It does look like there is a difference between the stock fender line and the tub behind that in front of the door. If you could move the front fender more flush with the rest of the tub it should line up because the JCR slider backing looks straight.I followed your thread to be honest and your build is a big reason I ended up with these and the epdm rubber backing. It's been this way since install and hasn't gotten worse. I haven't contacted any thing really hard on that side though. More noticeable now because I swapped some stock fenders on so thinner sheet metal. My jeep had some thicker homemade fenders when I bought it. I had to move those inward quite a bit for it to sit closer to flush. That is likely part of the issue. I have read not all tubs are exactly the same.

It seems the tub is angled in slightly where it meets the fender. I have the fender pushed inward but could probably move it in a bit more. The backing plate just pulls the fender sheet metal out.

I bolted the backing plate to the slider preloaded everything from underneath, then made my holes with the backing plate clamped to the tub with quickclamps. I have had it off and on quite a bit because it's always bugged me.

I also don't like their stupid logo lol and asked for without but never got a response.

I plan on pulling them off once it warms up so wanted to see if anyone was having a similar issue.

Yeah it's an interesting one. Balancing the fender not having a big step from being pushed inward too much. I want to correct it before it creates any other issues later on.I haven't seen this issue. It does look like there is a difference between the stock fender line and the tub behind that in front of the door. If you could move the front fender more flush with the rest of the tub it should line up because the JCR slider backing looks straight.

Now I'm probably going to mess with it tonight.

I can start a new thread if this getting side tracked. I just thought the info might be helpful for someone doing an install for the first time like I was.

Got them a little tighter but realized the fender isnt the issue. My previous install probably is the issue. The slider is straight not bent, my torque box is not bent with no noticeable deformation and the side of the tub is straight. It almost seems like the spacer pad on the rear of the slider, under the torque box, isn't tall enough.

I got frustrated with it so bolted the slider and backing plate together to fit up to the tub. Replicating a savvy style install as best I could with these sliders. With the plan to make sure everything was flush, flat and redrill holes if I need to. What I found was the slider plate is not level with the bottom of the tub or the bottom of the door when everything is up against the tub and torque box like it should be. It sits higher in the rear but the base plate is perfectly flat to the tub now. What was happening before was the slider was twisting the base plate pulling it away from the tub slightly near the front when you tightened everything up which is not ideal. I plan to mess with it some more this evening with an additional jack. Any input or advice is appreciated from those have done this before. Maybe the lj being the difference here? Some progress anyway and a learning experience.

When I originally installed these I followed jcr instructions with a blend of input from this site. Clamping the base plate and jacking the slider up with some pressure. I was never really satisfied with the results.

Got them a little tighter but realized the fender isnt the issue. My previous install probably is the issue. The slider is straight not bent, my torque box is not bent with no noticeable deformation and the side of the tub is straight. It almost seems like the spacer pad on the rear of the slider, under the torque box, isn't tall enough.

I got frustrated with it so bolted the slider and backing plate together to fit up to the tub. Replicating a savvy style install as best I could with these sliders. With the plan to make sure everything was flush, flat and redrill holes if I need to. What I found was the slider plate is not level with the bottom of the tub or the bottom of the door when everything is up against the tub and torque box like it should be. It sits higher in the rear but the base plate is perfectly flat to the tub now. What was happening before was the slider was twisting the base plate pulling it away from the tub slightly near the front when you tightened everything up which is not ideal. I plan to mess with it some more this evening with an additional jack. Any input or advice is appreciated from those have done this before. Maybe the lj being the difference here? Some progress anyway and a learning experience.

When I originally installed these I followed jcr instructions with a blend of input from this site. Clamping the base plate and jacking the slider up with some pressure. I was never really satisfied with the results.

From your original photos the backer plate looks to have an equal reveal between the door opening and top of backer plate. In the latest photo the reveal is wider toward the front versus back.

From JCR's video install

it appears the backer plate is held up in place and drilled. Then the slider is bolted into the clips on backers tabs, followed by "no preloading" and drilling up through the torque box and floor. *Cringe* (Nutserts all the way!)

If you bolt it up using the existing holes and the backer plate is flush across the entire piece without the slider on, does that change only after bolting the slider on?

It may be that one of the tabs on the backer could be welded on a touch high which could pull that area of the backer away from body creating your gap.

I have to say that the Savvy Rockers/Sliders I have and installed are in a different league than those. Worth every penny!

From JCR's video install

If you bolt it up using the existing holes and the backer plate is flush across the entire piece without the slider on, does that change only after bolting the slider on?

It may be that one of the tabs on the backer could be welded on a touch high which could pull that area of the backer away from body creating your gap.

I have to say that the Savvy Rockers/Sliders I have and installed are in a different league than those. Worth every penny!