One thing I wanted to bring up to the group to discuss is the spacer plates on some sliders that cover under the tub… the need for spacer plates is because the torque boxes are not level, they bend up about half way through the rocker area

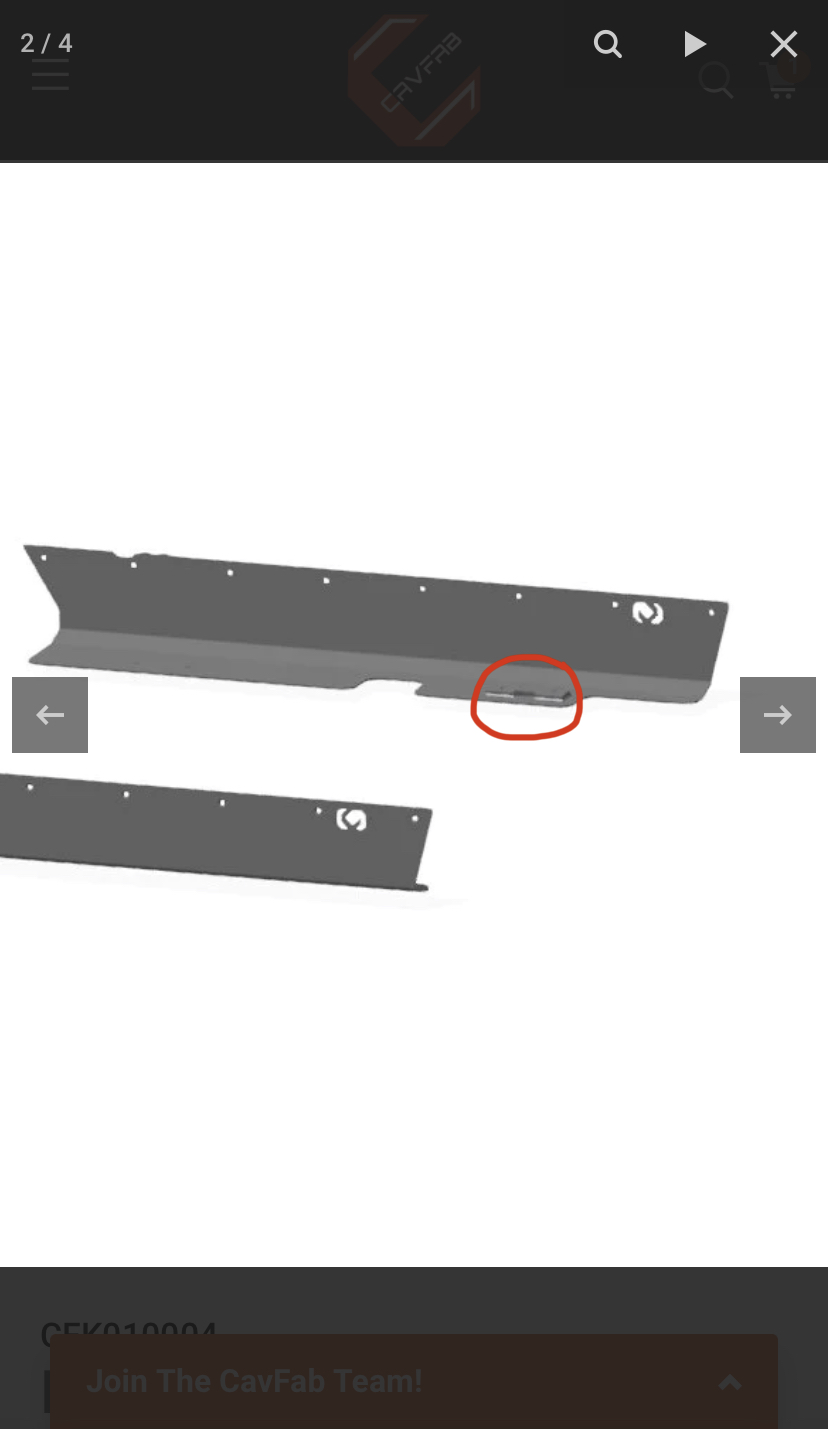

For example Cavfab (most cost effective choice for me at the minute) has one metal spacer plate between the rear most body mount and the middle body mount (these sliders are not body mount mounted, they bolt into the tub). My understanding is that spacer (circled in red in two pictures) mounts up against the torque box in the rear. Cav fab only has one of these where a much more experience slider (5x the cost) has 3 spacer plates (circled in blue).

My simple point of view is that more spacer plates help distribute the load into a bigger surface in the torque boxes.

What do you guys think?

For example Cavfab (most cost effective choice for me at the minute) has one metal spacer plate between the rear most body mount and the middle body mount (these sliders are not body mount mounted, they bolt into the tub). My understanding is that spacer (circled in red in two pictures) mounts up against the torque box in the rear. Cav fab only has one of these where a much more experience slider (5x the cost) has 3 spacer plates (circled in blue).

My simple point of view is that more spacer plates help distribute the load into a bigger surface in the torque boxes.

What do you guys think?