You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

STICKY Share Your 3D Design Files (or Sell a DIY Part)

- Thread starter SSTJ

- Start date

The design would be tricky without having the part in hand. But the printing would be straightforward and plenty strong with the right material. PTEG would be a great candidate for this part and it would be as strong or stronger than the original.How difficult would it be to do a turn signal switch early Gm type. Could this be done on a 3d printer or would moulding it be better for a one off part. How ,any hours would be involved?

View attachment 432376

Also, If you are getting prints that separate at the layers you need to adjust your printer settings. A good print shouldn't separate in this way.

Also, If you are getting prints that separate at the layers you need to adjust your printer settings. A good print shouldn't separate in this way.

https://www.protolabs.com/resources/blog/considerations-for-3d-printed-part-orientation/

What I am saying is that if you have prints that are coming apart at the layer boundaries there is a good chance you need to adjust your settings. Print direction does matter, but on a good print this is only because the layer lines will cause places of stress concentration. If you were to sand the parts after printing and remove the layer lines this will reduce the chances of fracturing along your layers.

Hoping for some help or guidance. I have zero experience with designing this 3D stuff though I have had a few things printed using files I've scrounged on the interweb.

I need to make a pair of small wedge shaped spacers to fit under replacement windshield washer fluid nozzles. The replacement nozzles I have can't be aimed high enough. I had another brand that used wedged shaped spacers to tilt them up but they weren't compatible with the TJ. The set I want use come with a flat rubber washer shaped slightly larger than the nozzle body. The spacer I want will sit under the nozzle and in, and on top of the rubber washer.

I scanned the rubber washer but don't know what to do with it from here. If anyone has experience with designing 3D templates and is willing to give me hand, I'll provide further details. Not sure if this is something worth time, but if it costs me a few bucks in compensation, I'm happy to do so. I don't need them printed, just need the file created.

These are the nozzles. The flat part faces the windshield and needs to be about 1/4" thick, tapering to the round part at the bottom which should be as thin as is possible to print. The printed part needs to fit inside the raised lip around the circumference of the rubber pad below.

Thoughts?

I need to make a pair of small wedge shaped spacers to fit under replacement windshield washer fluid nozzles. The replacement nozzles I have can't be aimed high enough. I had another brand that used wedged shaped spacers to tilt them up but they weren't compatible with the TJ. The set I want use come with a flat rubber washer shaped slightly larger than the nozzle body. The spacer I want will sit under the nozzle and in, and on top of the rubber washer.

I scanned the rubber washer but don't know what to do with it from here. If anyone has experience with designing 3D templates and is willing to give me hand, I'll provide further details. Not sure if this is something worth time, but if it costs me a few bucks in compensation, I'm happy to do so. I don't need them printed, just need the file created.

These are the nozzles. The flat part faces the windshield and needs to be about 1/4" thick, tapering to the round part at the bottom which should be as thin as is possible to print. The printed part needs to fit inside the raised lip around the circumference of the rubber pad below.

Thoughts?

Hoping for some help or guidance. I have zero experience with designing this 3D stuff though I have had a few things printed using files I've scrounged on the interweb.

I need to make a pair of small wedge shaped spacers to fit under replacement windshield washer fluid nozzles. The replacement nozzles I have can't be aimed high enough. I had another brand that used wedged shaped spacers to tilt them up but they weren't compatible with the TJ. The set I want use come with a flat rubber washer shaped slightly larger than the nozzle body. The spacer I want will sit under the nozzle and in, and on top of the rubber washer.

I scanned the rubber washer but don't know what to do with it from here. If anyone has experience with designing 3D templates and is willing to give me hand, I'll provide further details. Not sure if this is something worth time, but if it costs me a few bucks in compensation, I'm happy to do so. I don't need them printed, just need the file created.

These are the nozzles. The flat part faces the windshield and needs to be about 1/4" thick, tapering to the round part at the bottom which should be as thin as is possible to print. The printed part needs to fit inside the raised lip around the circumference of the rubber pad below.

Thoughts?

View attachment 436261

I think with a good measurements and a little trial and error this could be done in TinkerCAD pretty easily.

Match the footprint, slice the part at the required angle and cut a hole through the middle.

Print in ABS or PA for UV/heat resistance.

The issue I see is the threaded part of the nozzle going through the hood will now be at an angle and the nut will not "seat" properly. You would need an equivalently angled washer for under the hood, but it looks like there would not be enough threads with the two spacers installed.

I do and I can. Stay tuned.Do you have calipers to measure the rubber part? How much of an angle is needed?

Andy

Not 100% sure on the angle but it isn't critical given the nozzles spray angle is adjustable

Just no adjustable enough.

A wedge that tapers from 5-6mm down to 1mm would probably do it. More than that and I won't be able to get the nut on.

It's a low stress situation so my plan was to put a dab of high temp silicone under the bolt, but a second set of round wedged washers wouldn't be a bad idea.I think with a good measurements and a little trial and error this could be done in TinkerCAD pretty easily.

Match the footprint, slice the part at the required angle and cut a hole through the middle.

Print in ABS or PA for UV/heat resistance.

The issue I see is the threaded part of the nozzle going through the hood will now be at an angle and the nut will not "seat" properly. You would need an equivalently angled washer for under the hood, but it looks like there would not be enough threads with the two spacers installed.

Over in the other 3D printing thread I posed this little part I printed.

[URL]https://wranglertjforum.com/threads/what-have-you-3d-printed-for-your-tj.55555/post-1338748[/URL]

View attachment 432197

Great, thanks. Added it to the list.

Ok, keep us posted. And what is it?Printed this overnight in PETG. If it works it will be part of a how-to. Andy

View attachment 432241

Does anyone know of 3D printing the bushing/washer that breaks on the front seats of our TJ's? Both my seats wobble like crazy

There is another thread on here, somewhere, about one recommended product that others have used. In fact, I think it was one of my threads/questions, so I'll see if I find it.

But as I've posted elsewhere, I just took some electrical tape, cut it down the middle long-ways, and wrapped it around and around the inside of that mounting spot. So far, works well!

EDIT: Oops, I see someone else already provided a link.

Hoping for some help or guidance. I have zero experience with designing this 3D stuff though I have had a few things printed using files I've scrounged on the interweb.

I need to make a pair of small wedge shaped spacers to fit under replacement windshield washer fluid nozzles. The replacement nozzles I have can't be aimed high enough. I had another brand that used wedged shaped spacers to tilt them up but they weren't compatible with the TJ. The set I want use come with a flat rubber washer shaped slightly larger than the nozzle body. The spacer I want will sit under the nozzle and in, and on top of the rubber washer.

I scanned the rubber washer but don't know what to do with it from here. If anyone has experience with designing 3D templates and is willing to give me hand, I'll provide further details. Not sure if this is something worth time, but if it costs me a few bucks in compensation, I'm happy to do so. I don't need them printed, just need the file created.

These are the nozzles. The flat part faces the windshield and needs to be about 1/4" thick, tapering to the round part at the bottom which should be as thin as is possible to print. The printed part needs to fit inside the raised lip around the circumference of the rubber pad below.

Thoughts?

View attachment 436261

So no progress on this conversation?

Ok, keep us posted. And what is it?

See the finished version here along with a bunch of other 3D printed parts: https://wranglertjforum.com/threads/sony-xav-xa3200-head-unit-install.71190/

Andy

So no progress on this conversation?

Not since my last post. The TJ is packed and I am heading up to the mountains for some camping for a few days.

Lucky I didn't have to cancel the trip. I turned my homes central air on this past Sunday not knowing that the condensation vent line had clogged and ultimately froze and ruptured over the winter. I came home Monday to water running out of my ceiling. Destroyed the ceiling and most of the contents in the room below. Got a quote from $1500 - $2400 to replace 25' of PVC. F you covid. Looks like I am going to have to replace the AC unit, which is 22 years old and survived the flooding from Superstorm Sandy.

This is Jeep adjacent because I use the Jeep to get to the woods to shoot.

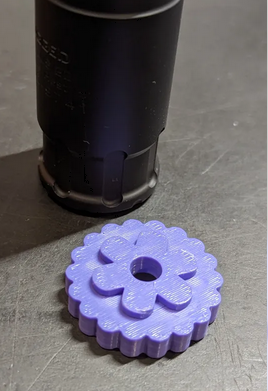

Rugged Oculus 22 end cap tool and baffle alignment tool.

https://www.printables.com/model/517067-rugged-oculus-22-endcap-tool

https://www.printables.com/model/517064-rugged-oculus-22-baffle-alignment-tool

Rugged Oculus 22 end cap tool and baffle alignment tool.

https://www.printables.com/model/517067-rugged-oculus-22-endcap-tool

https://www.printables.com/model/517064-rugged-oculus-22-baffle-alignment-tool

I like that purple! Might have to get some. Andy

Bambu Labs "PLA Tough" in Purple.

Bambu Labs "PLA Tough" in Purple.

Heads up that they're doing a gratitude bundle for 2 pla-cf spools for $2. You have to sign up for their newsletter.

Heads up that they're doing a gratitude bundle for 2 pla-cf spools for $2. You have to sign up for their newsletter.

Well I got to go look for that. I litterly placed an order for some support filament and matte PLA an hour ago.....