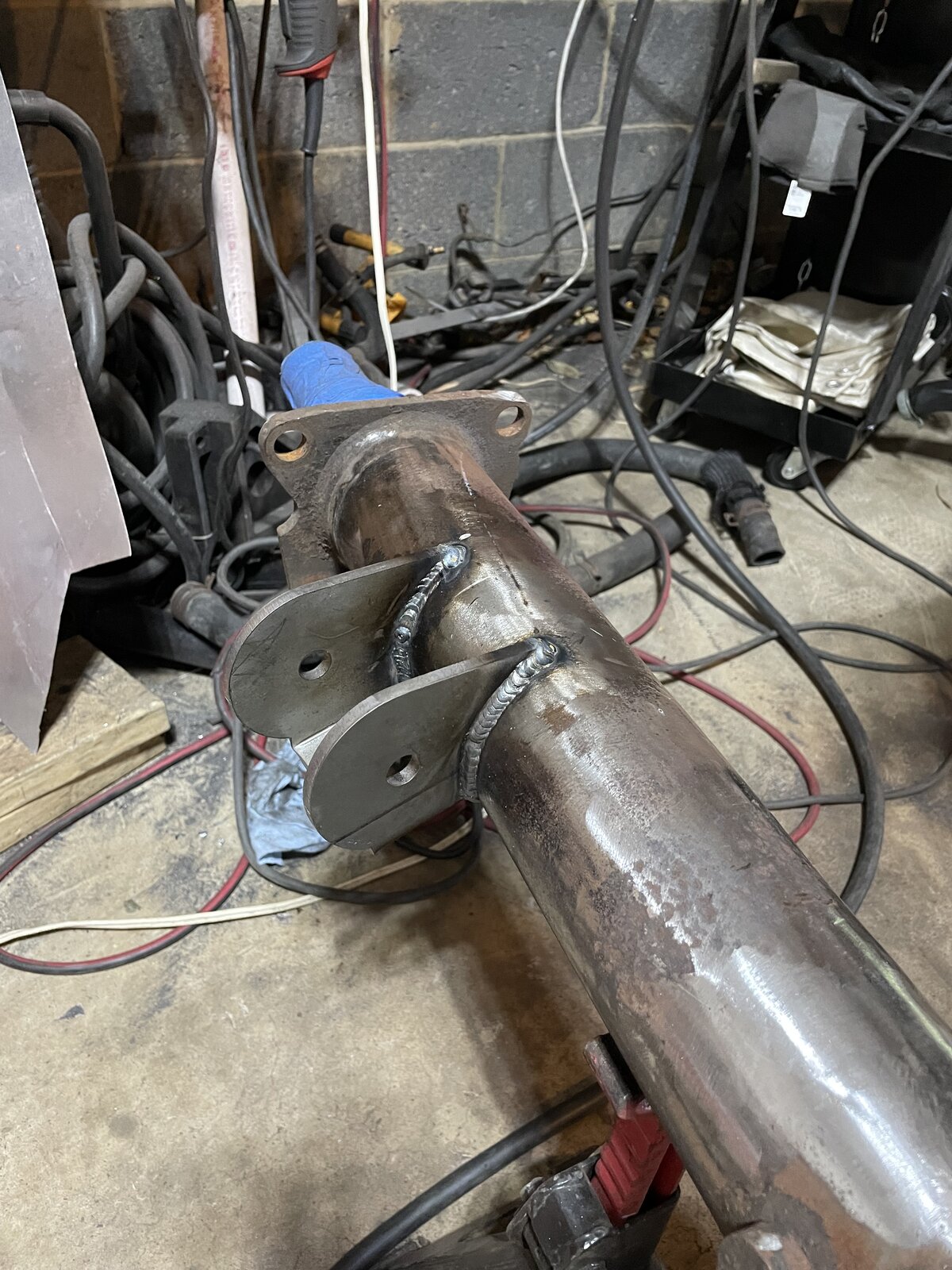

I ordered some Corvette headers as they should be better for the drivers side. While I wait for those so I can finish boxing in the motor mounts, I started working on the Sterling 10.5. I got the upper and lower CA brackets burned in:

I need to start mocking up the rear shock towers for the 14” ORIs. Hopefully I don’t need to cut into the tub, but I probably won’t get that lucky.

I need to start mocking up the rear shock towers for the 14” ORIs. Hopefully I don’t need to cut into the tub, but I probably won’t get that lucky.