That is awesome, I’m really excited to hear how they perform. I have the chance to pick up a set of 4 12” ones....all right all the way down to the bottom.........look Ma no stands. she's standin on her own. even with all the weight of the front end and i even stood on the bumper that last inch is hard and it's not gonna go until slammed. which ain't gonna happen.

time to bust out my double feed set-up and if i can vent um, i can fill um.

dig the rake, hope that AS is good or it'll be a wild ride.

View attachment 152773

View attachment 152774

View attachment 152775

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Someguys 04

- Thread starter someguysjeep

- Start date

we got her up. started with 90# in the bottom and it took 295-300# in the top end to lift me to mid stroke.

she sits nice i like it, so far.

she sits nice i like it, so far.

it's where they suggest as a start point. it feels stiff.

i got onto the front bumper and bounced up and down....and it don't move. so i think 90# might be a little high.

i have a download for corner weight and projected settings i need to mess around with and do some figuring.

i got onto the front bumper and bounced up and down....and it don't move. so i think 90# might be a little high.

i have a download for corner weight and projected settings i need to mess around with and do some figuring.

I’ve read that you don’t want to go much lower than 70/80 on the bottom, but that depends more on top bottom relationship.it's where they suggest as a start point. it feels stiff.

i got onto the front bumper and bounced up and down....and it don't move. so i think 90# might be a little high.

i have a download for corner weight and projected settings i need to mess around with and do some figuring.

35-300# range in the low end, 0-600# on the top end.

90#/290# is baseline on a 4500# vehicle..

90#/290# is baseline on a 4500# vehicle..

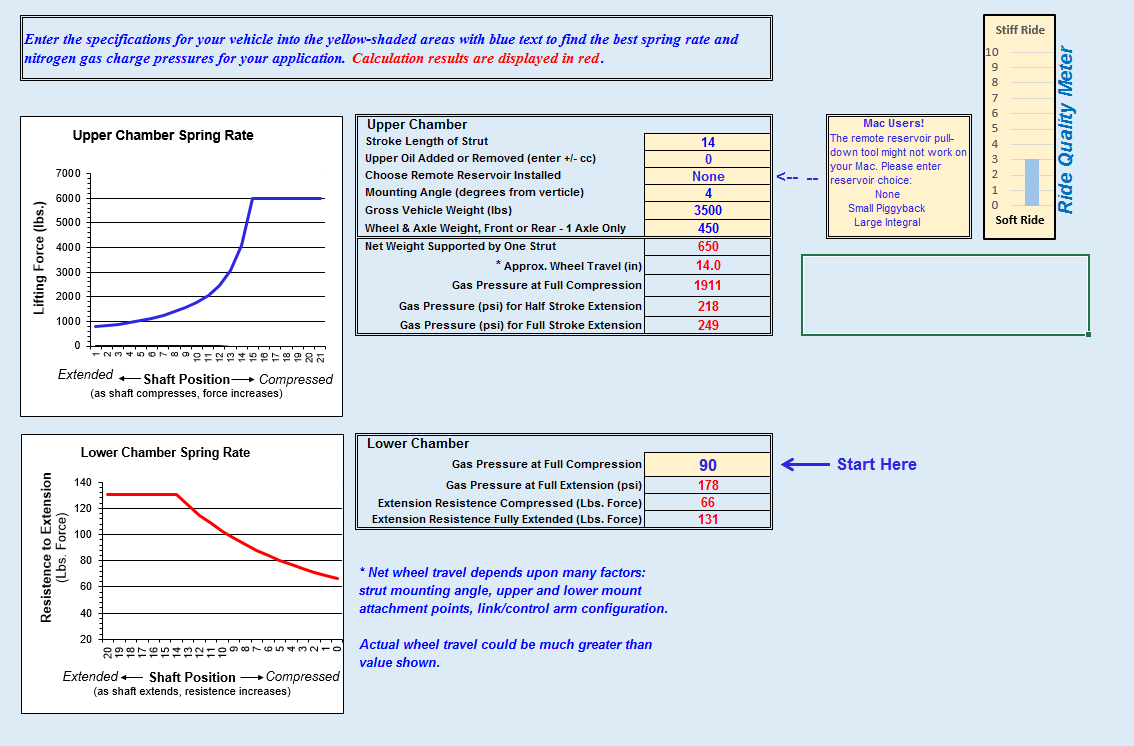

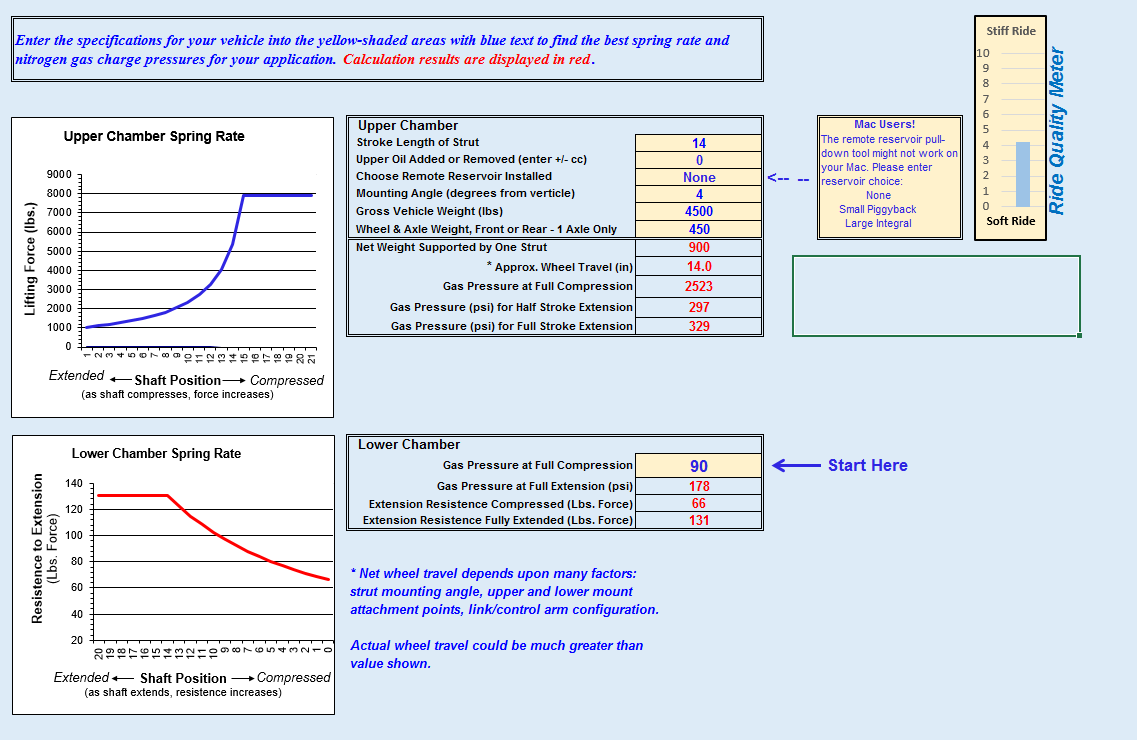

ok, here's some #'s off their worksheet.

there is something funky about the weight distribution.

1st example is 3500# gross weight, 450# axle weight.

with 90# in the bottom they suggest pressure to reach 1/2 stroke is 218#

so this ain't right ^.

they take 3500 divide it by 4 and take away the axle weight and call it 650# a corner.

nope nope nope. we are not weighted this way, especially me with an empty ass end.

so i attempted to work it backwards to see what that nets.

example 2 is the resemblance of 4500# set up 90#/300#. like i am, or what i needed to reach this point.

this is much more reflective of a 3500# vehicle split with a 60/40 front to rear weight ratio minus the axle weight.

this calculation brings the front corner weights up from 650# to 855#.

the representation in the 2nd worksheet of 900# corner weight is only 45# off my uneducated guesstimate of a 3500 GVW. if i'm really 3650 i'm real close .

guess i will not make changes until i can feel it under power. this will be my baseline.

there is something funky about the weight distribution.

1st example is 3500# gross weight, 450# axle weight.

with 90# in the bottom they suggest pressure to reach 1/2 stroke is 218#

so this ain't right ^.

they take 3500 divide it by 4 and take away the axle weight and call it 650# a corner.

nope nope nope. we are not weighted this way, especially me with an empty ass end.

so i attempted to work it backwards to see what that nets.

example 2 is the resemblance of 4500# set up 90#/300#. like i am, or what i needed to reach this point.

this is much more reflective of a 3500# vehicle split with a 60/40 front to rear weight ratio minus the axle weight.

this calculation brings the front corner weights up from 650# to 855#.

the representation in the 2nd worksheet of 900# corner weight is only 45# off my uneducated guesstimate of a 3500 GVW. if i'm really 3650 i'm real close .

guess i will not make changes until i can feel it under power. this will be my baseline.

Lookin great.... Always a great feeling when you get those tires back on for the first time.

I'm wondering if I'll make this year or if it won't be until next year. Keep it up you are getting there. I'm glad you are the one figuring out how to run those ORI's.

I'm wondering if I'll make this year or if it won't be until next year. Keep it up you are getting there. I'm glad you are the one figuring out how to run those ORI's.

today was crap woke up to 3" of fresh snow and 30* temps. never got over 44* and more of the same tomrw.

i did manage to pull the front bumper, and get that front frame area cleaned up nicely. i built a small tent and stuck my heater in there and got it warm enough to shoot some paint onto it.

tomrw i'll try and get the new bumper on and maybe some of the winch, all that weights gonna play in the final results of the struts.

kinda itchin to get into the UA as well.

i got my buttons today for the lockers and lights, they fit into the OE switch panel, and you really can't tell they are not factory.

i got the parts for the brakes but i'm not rollin around on the ground in the snow so it's gonna wait for Saturday , it's supposed to be in the 50's

i did manage to pull the front bumper, and get that front frame area cleaned up nicely. i built a small tent and stuck my heater in there and got it warm enough to shoot some paint onto it.

tomrw i'll try and get the new bumper on and maybe some of the winch, all that weights gonna play in the final results of the struts.

kinda itchin to get into the UA as well.

i got my buttons today for the lockers and lights, they fit into the OE switch panel, and you really can't tell they are not factory.

i got the parts for the brakes but i'm not rollin around on the ground in the snow so it's gonna wait for Saturday , it's supposed to be in the 50's

Bummer, hope that weather doesn't find it's way out here. It's going to be 70* here tomorrow so I am hoping I can get some work done in the garage. Leg is getting better.

Hope your weather warms up.

Hope your weather warms up.

well fri was a bust, snowed all day.......it was still soaked wet and chilling cold most of this morn so brakes tomrw now.

did manage to get the easy part of the AR done today.

as well as the new bumper and winch plate mounted. the transfer case cross member is down and i've begun to see what i'm gonna have to do to mount the UA.

the transfer case support i had built was/is coincidentally the same drop as the Savvy piece.

did manage to get the easy part of the AR done today.

as well as the new bumper and winch plate mounted. the transfer case cross member is down and i've begun to see what i'm gonna have to do to mount the UA.

the transfer case support i had built was/is coincidentally the same drop as the Savvy piece.

Last edited:

finally got started into those brakes today and after about the 3rd bad flare on the last piece. i had enough of that cheap ass flare tool.

i'll be getting a new 1 tomrw.

so i moved along to mount the body of the winch and get the bumper snugged up. the bumper hooks replace the grade 8 bumper hardware with longer grade 5's. but i want 8's in there, so those will be swapped soon.

got back under it and got old cross member brackets cut off and played with the UA cross member a little more. i don't see a way to squeeze by with just a 1"BL. i need an inch up and that'll put the tranny housing right on the tunnel seam. and the tranny lines are contacting the tunnel wall already.

1 of the trans lines is weeping at the radiator. it's already a little tighter to the DS than i like, so i need to address them.

i'll be getting a new 1 tomrw.

so i moved along to mount the body of the winch and get the bumper snugged up. the bumper hooks replace the grade 8 bumper hardware with longer grade 5's. but i want 8's in there, so those will be swapped soon.

got back under it and got old cross member brackets cut off and played with the UA cross member a little more. i don't see a way to squeeze by with just a 1"BL. i need an inch up and that'll put the tranny housing right on the tunnel seam. and the tranny lines are contacting the tunnel wall already.

1 of the trans lines is weeping at the radiator. it's already a little tighter to the DS than i like, so i need to address them.

@mrblaine, i don't wanna pollute toxi's thread with my BS so i'm draggin it over.

that crap about my trans lines and the drive shaft.

i got enough room for the DS but they are into the tub on the way up to mount my UA.

the bend from behind the cats around the bell could have been 3" back and 3" less offset.

i need to do something with those lines.

now on toximus' thread you mentioned the possibility of using AN fittings to change the path. i pulled the fitting and to me it appears to be a -6AN, would you agree this should be correct?

if so my intention would be to replace my fittings with 90's and rubber hose jumpers to remove all of the interference's.

also considering ditching all the metal lines and running rerouted rubber hoses. soon there will be a trans fluid cooler in this equation as well.

that crap about my trans lines and the drive shaft.

i got enough room for the DS but they are into the tub on the way up to mount my UA.

the bend from behind the cats around the bell could have been 3" back and 3" less offset.

i need to do something with those lines.

now on toximus' thread you mentioned the possibility of using AN fittings to change the path. i pulled the fitting and to me it appears to be a -6AN, would you agree this should be correct?

if so my intention would be to replace my fittings with 90's and rubber hose jumpers to remove all of the interference's.

also considering ditching all the metal lines and running rerouted rubber hoses. soon there will be a trans fluid cooler in this equation as well.

Do you have a pic of the fittings?@mrblaine, i don't wanna pollute toxi's thread with my BS so i'm draggin it over.

that crap about my trans lines and the drive shaft.

i got enough room for the DS but they are into the tub on the way up to mount my UA.

the bend from behind the cats around the bell could have been 3" back and 3" less offset.

i need to do something with those lines.

now on toximus' thread you mentioned the possibility of using AN fittings to change the path. i pulled the fitting and to me it appears to be a -6AN, would you agree this should be correct?

if so my intention would be to replace my fittings with 90's and rubber hose jumpers to remove all of the interference's.

also considering ditching all the metal lines and running rerouted rubber hoses. soon there will be a trans fluid cooler in this equation as well.

View attachment 154565

fitting end on the vehicle? or fitting i plan to replace it with?

i'll have to pull the fitting back loose and get a pic, the sweep is so tight the fitting won't pull back so i'll have to get it's adapter on the housing.

the new, would be a 90* sweep similar to this.

i'll get pic off the trans as soon as i can... it's 35* outside ATM.

i'll have to pull the fitting back loose and get a pic, the sweep is so tight the fitting won't pull back so i'll have to get it's adapter on the housing.

the new, would be a 90* sweep similar to this.

i'll get pic off the trans as soon as i can... it's 35* outside ATM.

pic of whats in the housing, male end.Do you have a pic of the fittings?

and tube end, dark as dirt but i think i do see a double flare there. i can try another better lit if needed.

if so that's not the fitting i want, above.

would the same rules apply here like a high pressure sys.? meaning no sharp 90's just sweeps?

A standard push lock 90 degree AN fitting would be much lower profile and fit there. I would consider SS flex with low profile ends. Not specifically this kit but similar-pic of whats in the housing, male end.

and tube end, dark as dirt but i think i do see a double flare there. i can try another better lit if needed.

if so that's not the fitting i want, above.

would the same rules apply here like a high pressure sys.? meaning no sharp 90's just sweeps?

View attachment 154581

View attachment 154582

https://www.summitracing.com/parts/sum-tankkit1?seid=srese1&gclid=Cj0KCQjws_r0BRCwA...z4XLh9JixkRPKqAwE4kcjEDIH3WsExGYaArfiEALw_wcB

Short section of SS braided, low profile sweep 90 at the trans, other end straight female, that goes onto a compression x -6 male on the hard line that you cut back and shortened.

Do the trans hard lines go behind the exhaust like they are supposed to?

yes routed behind the mini cats, it's that point back thats the issue.

thanks once again.

thanks once again.

Last edited:

A standard push lock 90 degree AN fitting would be much lower profile and fit there. I would consider SS flex with low profile ends. Not specifically this kit but similar-

https://www.summitracing.com/parts/sum-tankkit1?seid=srese1&gclid=Cj0KCQjws_r0BRCwARIsAMxfDRgW3jzZkkN5mRR1X2gFdGgz4XLh9JixkRPKqAwE4kcjEDIH3WsExGYaArfiEALw_wcB

Short section of SS braided, low profile sweep 90 at the trans, other end straight female, that goes onto a compression x -6 male on the hard line that you cut back and shortened.

Do the trans hard lines go behind the exhaust like they are supposed to?

i tried to follow the 2nd link but it dead ended on me.

getting confused over info sources.

there is double flare there not a single i'd think i'd expect to see from information about a 37* AN.

it's looks to be, since it is double flared a 45* SAE? many sources claim the trans is a 45*. am i wrong here?

i'd have to change the fitting in the housing to a -6. or adapt the 45*to 37* then into the 90.

it's all getting way more complicated than needs to be.

i'm thinkin, buy 4 pieces of the 3/8 tube to -6AN hose. and 3ft of braided.....i'll retain the connections at the trans (cut n twist) and jump over to my open ends once the bends are tweeked.