Some great work here. I love it when someone pays attention to little details!A little update on the brakes

View attachment 316742View attachment 316744

View attachment 316739

View attachment 316740

Using some of the wisdom of some senior members on this forum, the entire system will utilize AN3 fittings. All easily replaced.

I stole the little "rail" that the hardline tabs bolt through from toximus, who stole it from Blaine, who stole... probably invented the idea. It should keep any sticks from getting between the axle and brake line.

AN3 female soft lines have been ordered to go from the male AN3 fitting near the end of the axle to the brake caliper, which will get a 90 degree banjo to AN3 male.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trail_Krawler & Trail_Willys

- Thread starter kmas0n

- Start date

Thanks!!Some great work here. I love it when someone pays attention to little details!

Since*most* of the fabrication is done on the rear end, gave the axle a coat of paint. And installed the brake hardware.

Just waiting on the flex lines. I also ordered some of these...

https://www.tmrcustoms.com/products/chassis-link-zip-tie-tabs

... to organize brake lines/locker wiring/vent tube to the driver side upper control arm.

Just waiting on the flex lines. I also ordered some of these...

https://www.tmrcustoms.com/products/chassis-link-zip-tie-tabs

... to organize brake lines/locker wiring/vent tube to the driver side upper control arm.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

I'm running these brakes on my LJ and can confirm they do great! The rear is a single piston. Now would be a great time to plum for cutting brakes, just saying.The brakes will be oem for the m210/220 axles (JLUR). Huge rotors, twin piston calipers, and can stop my 5k pound JL on 37's no problem. I'm trying to keep the TJ near 4k so it should be plenty

Boom - Have you ever calculated your “mean time between cutting brake recommendations”?…I'm running these brakes on my LJ and can confirm they do great! The rear is a single piston. Now would be a great time to plum for cutting brakes, just saying.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

I'm running a solid 15.5 day average MTBCBR. Looking to improve my performance in that metric this yearBoom - Have you ever calculated your “mean time between cutting brake recommendations”?…

Good to know about the brakes being good on the LJ.I'm running these brakes on my LJ and can confirm they do great! The rear is a single piston. Now would be a great time to plum for cutting brakes, just saying.

however, I'm not a cutter

Thanks!Man that is a CLEAN looking setup. I wish I could tell you what the ring was.

So now everything is wrapping up on the rear, I wanted to share my bump stop logic. I'll define a few things.

Full bump. Both shocks fully compressed, as might happen in whoops, or an airborne situation. Most likely at high speed.

Full flex. Passenger shock completely compressed, driver shock completely extended. Likely to happen Rock crawling, but at slow speeds.

Half flex... I made this up. passenger side fully compressed, driver side half compressed. Likely to happen Rock crawling with enthusiasm. Not full airborne, weight still on the tires, but a sudden harsh impact on only one tire.

I intentionally put my bump stops, inboard of the shocks. So full bump and full flex use pretty close to the same amount of bump stop.

I didn't take a pic of full bump, because it's not needed.

The picture below is of full flex. There is only 3/8" of space between the axle and fully compressed bump stop. Meaning that the 2" travel bump stop will have to compress 1 5/8 to full flex. Because this only happens at lower speeds, I believe this will be adequate. There is still the "emergency" poly disc on the shock shaft that's good for a hard impact or 50, but can split and fall off.

This next pics shows half flex. A likely scenario with aggressive driving. The bump stop is hard against the axle tube at the same time the shock bottoms out. Since this will have much higher shaft speed and momentum, the bump stop will protect the shock.

The green take disc is the contact location of the bump pad, at full bump.

Full bump. Both shocks fully compressed, as might happen in whoops, or an airborne situation. Most likely at high speed.

Full flex. Passenger shock completely compressed, driver shock completely extended. Likely to happen Rock crawling, but at slow speeds.

Half flex... I made this up. passenger side fully compressed, driver side half compressed. Likely to happen Rock crawling with enthusiasm. Not full airborne, weight still on the tires, but a sudden harsh impact on only one tire.

I intentionally put my bump stops, inboard of the shocks. So full bump and full flex use pretty close to the same amount of bump stop.

I didn't take a pic of full bump, because it's not needed.

The picture below is of full flex. There is only 3/8" of space between the axle and fully compressed bump stop. Meaning that the 2" travel bump stop will have to compress 1 5/8 to full flex. Because this only happens at lower speeds, I believe this will be adequate. There is still the "emergency" poly disc on the shock shaft that's good for a hard impact or 50, but can split and fall off.

This next pics shows half flex. A likely scenario with aggressive driving. The bump stop is hard against the axle tube at the same time the shock bottoms out. Since this will have much higher shaft speed and momentum, the bump stop will protect the shock.

The green take disc is the contact location of the bump pad, at full bump.

Last edited:

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Concur with wildman. The coilover setup REALLY cleans up the axle. Love it.Does anyone know what this aluminum ring is? It's free to move around. Some kinda anti abrasion ring?

View attachment 317284

Thanks!Concur with wildman. The coilover setup REALLY cleans up the axle. Love it.

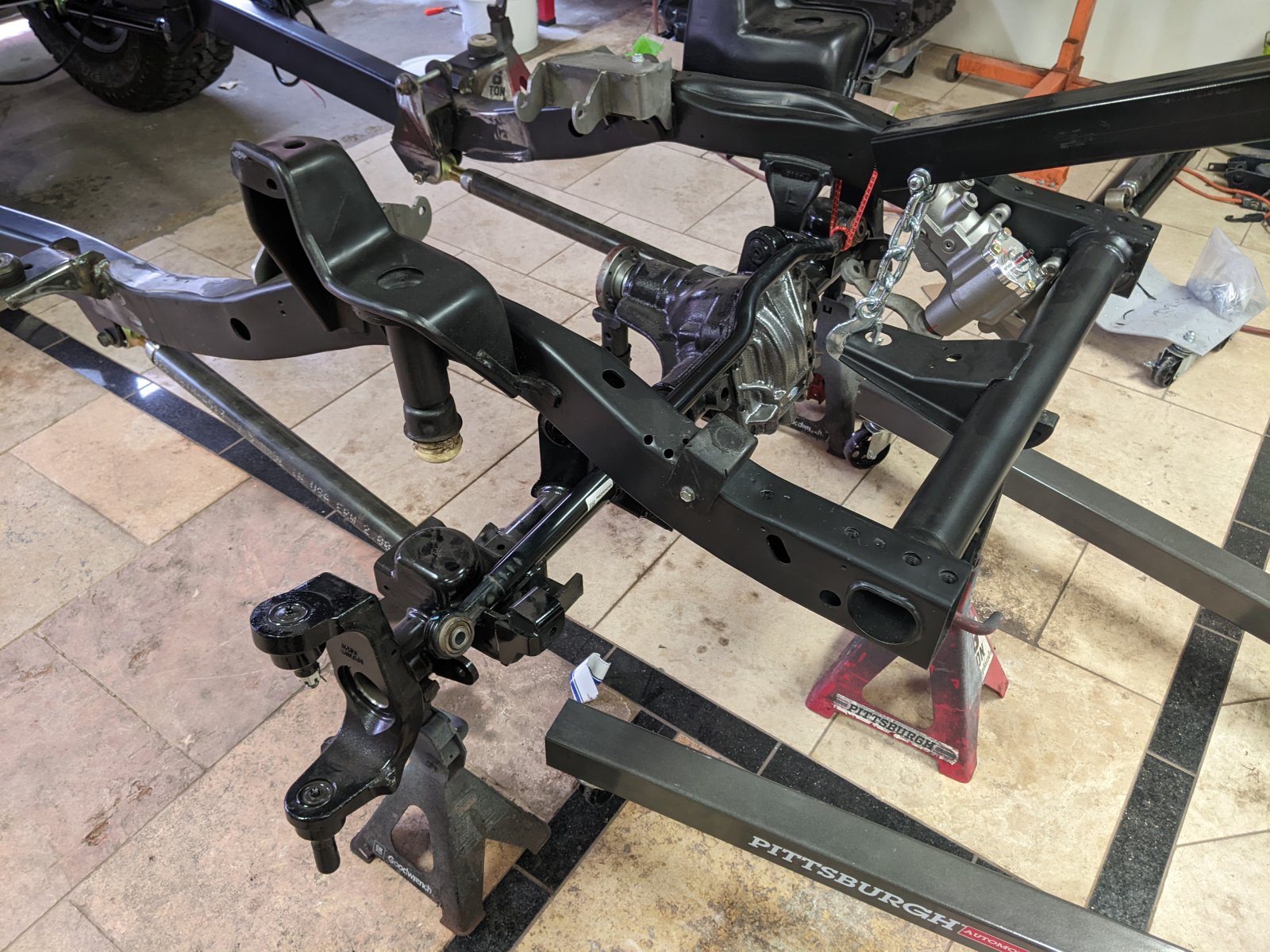

Mock up for the front axle and suspension had begun. First time doing this, so I picked a target wheel base of 103" (approx 7" stretch in the rear, and 3" in the front. It's clear that everything is going in interfere with everything else, but it's a starting point. The mock up track bar is actually from the rear of a JL I had laying around.

The ring may be a manufacturer date or certification tag. Check for any markings.Does anyone know what this aluminum ring is? It's free to move around. Some kinda anti abrasion ring?

View attachment 317284

You're probably right. It just says "Earls 605"The ring may be a manufacturer date or certification tag. Check for any markings.

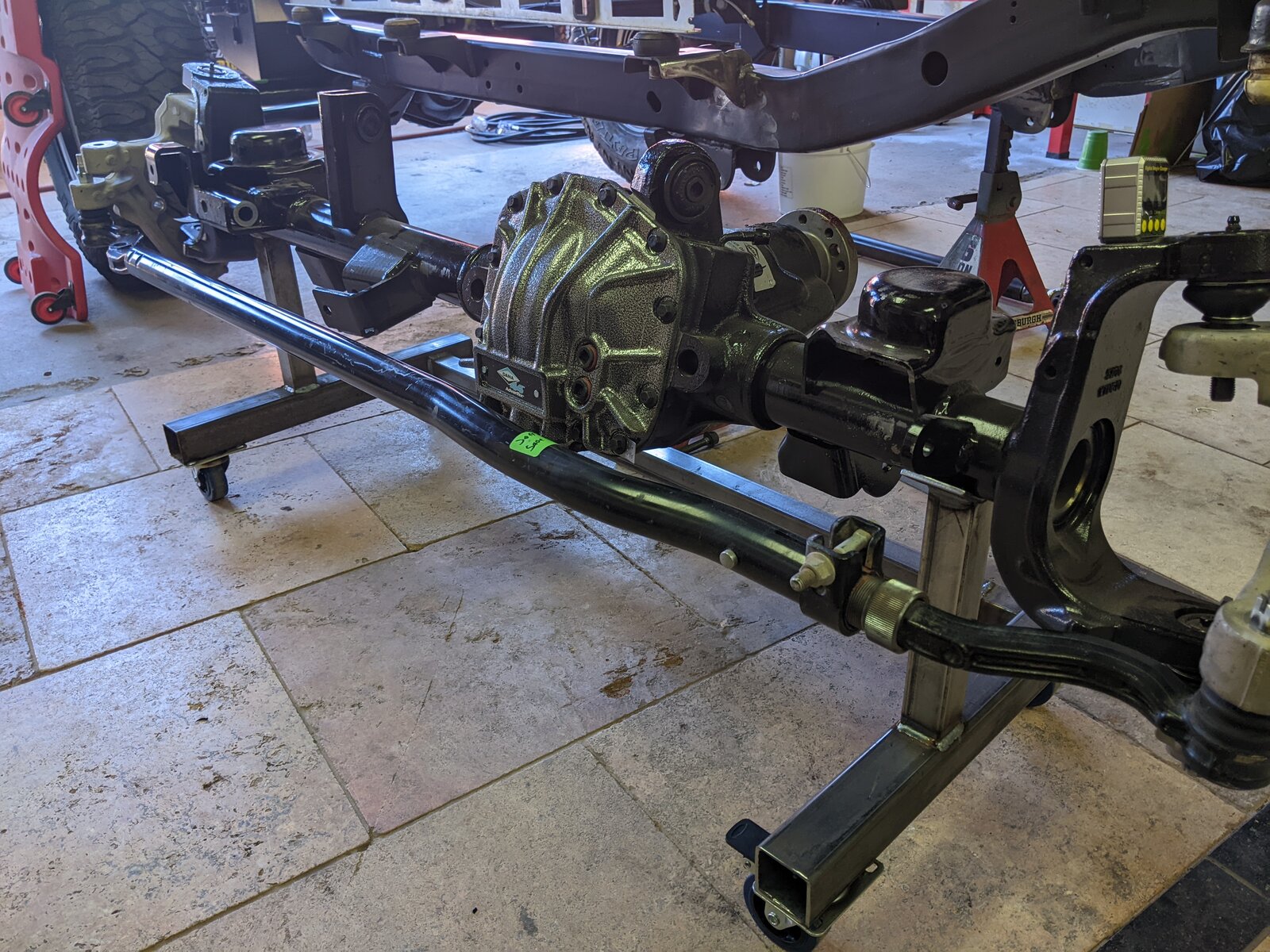

I built a cart for the front axle. I lost count of how many times the rear fell off the jack stands trying to kill me. The cart holds the axle at the right height and after I get all of the brackets cut off, I'll make a pinion support so I can set caster at 6°. This should make it much simpler to mock up the 3 link and steering.

That's pretty fancy. I like it.I built a cart for the front axle. I lost count of how many times the rear fell off the jack stands trying to kill me. The cart holds the axle at the right height and after I get all of the brackets cut off, I'll make a pinion support so I can set caster at 6°. This should make it much simpler to mock up the 3 link and steering.

View attachment 320926

Well.

It's off.

Not one of my favorite projects, but not having an engine, body or axle certainly sped things up.

It's off.

Not one of my favorite projects, but not having an engine, body or axle certainly sped things up.

Last edited:

The plasma cutter sliced the 1/4" brackets off the 44 effortlessly. Still need to clean up the leftovers with an angle grinder.

Now mocking up with engine in place to start determining true hard bump... The point where the axle hits the engine. This is the absolute limit of up-travel and must never happen. I have to take into account engine mount flex, frame flex and twist. There might be better ways to do this, but this is my logic...

first, place the axle where I want it, in this case, about 3" forward of the factory axle.

Set the frame and axle at ride height. I'm wanting at least 5-6" of up travel with the equivalent of a 4" lift and 1" body lift.

Fabricate upper control arm... tuck it low and get the arm near parallel to the lowers.

Fabricate trackbar.

See what hits... does the axle hit the engine first or the upper control arm hit the engine mount?

Fabricate drag link and start playing with interference... give up wheelbase sparingly.

Interestingly, I've determined the drag link needs to be about 37.25... which seems to be the same measurement as the factory TJ drag link. The axle is a lot wider, but the knuckle is shaped differently. amazingly, a JL rear trackbar is 37.25 so it will work great as a mock up tool for the TJ's trackbar... the trackbar and drag link are almost exactly the same length. The short length of DOM tube sitting on the frame is going to be the axle side track bar mount, in single shear.

This is getting exciting

Now mocking up with engine in place to start determining true hard bump... The point where the axle hits the engine. This is the absolute limit of up-travel and must never happen. I have to take into account engine mount flex, frame flex and twist. There might be better ways to do this, but this is my logic...

first, place the axle where I want it, in this case, about 3" forward of the factory axle.

Set the frame and axle at ride height. I'm wanting at least 5-6" of up travel with the equivalent of a 4" lift and 1" body lift.

Fabricate upper control arm... tuck it low and get the arm near parallel to the lowers.

Fabricate trackbar.

See what hits... does the axle hit the engine first or the upper control arm hit the engine mount?

Fabricate drag link and start playing with interference... give up wheelbase sparingly.

Interestingly, I've determined the drag link needs to be about 37.25... which seems to be the same measurement as the factory TJ drag link. The axle is a lot wider, but the knuckle is shaped differently. amazingly, a JL rear trackbar is 37.25 so it will work great as a mock up tool for the TJ's trackbar... the trackbar and drag link are almost exactly the same length. The short length of DOM tube sitting on the frame is going to be the axle side track bar mount, in single shear.

This is getting exciting