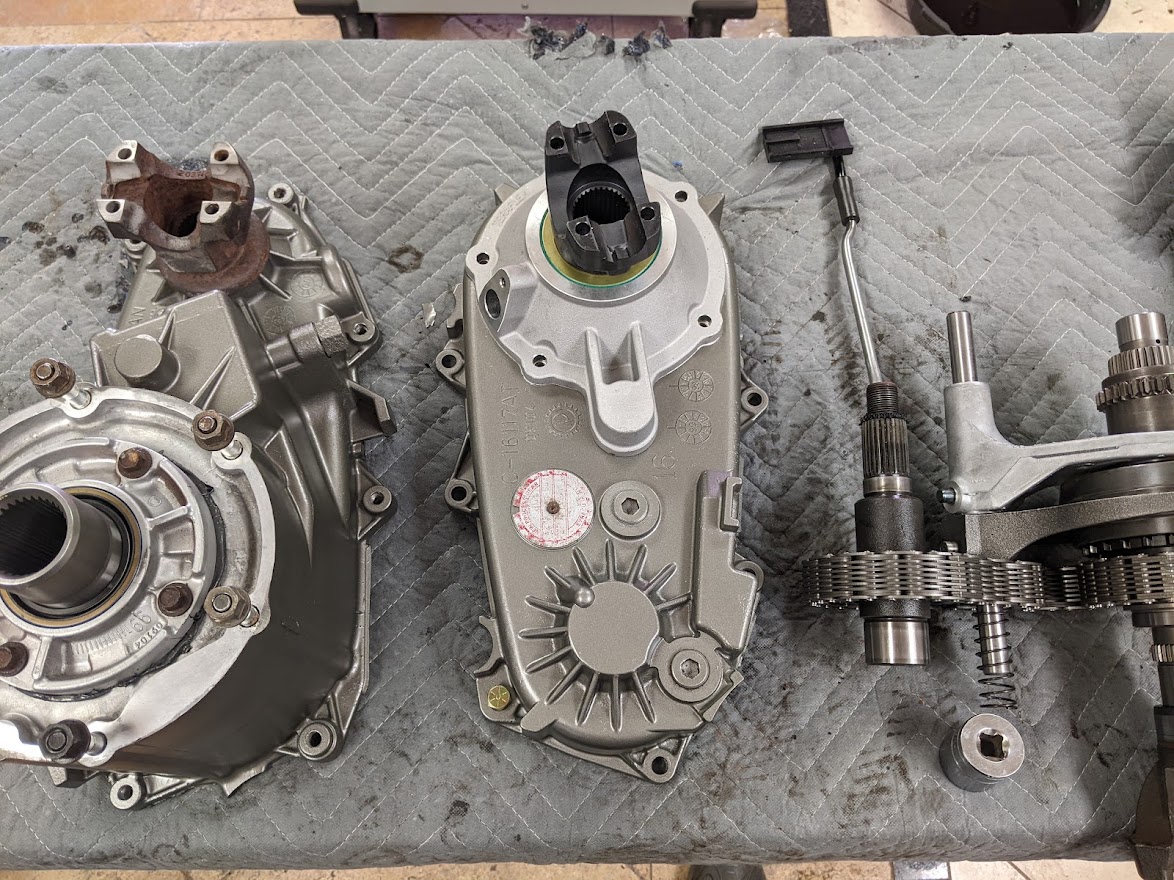

In the middle of upgrading the the NP231. The input shaft has to be replaced to mate up to the 6L80 transmission correctly, that's really just a R&R. In an effort to keep driveline angles to a minimum I replaced the current SYE with a super short SYE from Terraflex. This will allow my driveshaft to be about 3" longer. During the disassembly I dropped the debris magnet on the ground and it shattered... so Now I'm waiting for a replacement. Sucks when a relatively easy project gets sidelined by something like a broken magnet. I took the opportunity to clean up the case and paint it "cast iron" gray.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trail_Krawler & Trail_Willys

- Thread starter kmas0n

- Start date

I like the paint! Looks good! Hurry up and finish by fall so we can wheel it!In the middle of upgrading the the NP231. The input shaft has to be replaced to mate up to the 6L80 transmission correctly, that's really just a R&R. In an effort to keep driveline angles to a minimum I replaced the current SYE with a super short SYE from Terraflex. This will allow my driveshaft to be about 3" longer. During the disassembly I dropped the debris magnet on the ground and it shattered... so Now I'm waiting for a replacement. Sucks when a relatively easy project gets sidelined by something like a broken magnet. I took the opportunity to clean up the case and paint it "cast iron" gray.

View attachment 333363

Just another year or three!I like the paint! Looks good! Hurry up and finish by fall so we can wheel it!

I didn't get to touch it for about two months during spring break... business was good. I'm easing back into it. Piecing together steering and front suspension now.

Dupli-color engine. Goes on smooth, dries fast and seems to be pretty tough.What paint is that, love the look.

Before painting, I went at it with a dremel and an assortment of small wire brushes, Everything then got sprayed with brake cleaner, and wiped down with wax and tar remover.

https://www.instagram.com/p/CeG90jXrGQ2/

https://www.instagram.com/p/CeG90jXrGQ2/

Last edited:

In the middle of upgrading the the NP231. The input shaft has to be replaced to mate up to the 6L80 transmission correctly, that's really just a R&R. In an effort to keep driveline angles to a minimum I replaced the current SYE with a super short SYE from Terraflex. This will allow my driveshaft to be about 3" longer. During the disassembly I dropped the debris magnet on the ground and it shattered... so Now I'm waiting for a replacement. Sucks when a relatively easy project gets sidelined by something like a broken magnet. I took the opportunity to clean up the case and paint it "cast iron" gray.

View attachment 333363

Do you have any concerns about the 231 holding up to the extra power? I'm doing a similar engine/trans swap and am debating between the 231 and standard JK 241 or 241c. I know you can do a 6 gear planetary and wide chain for the 231, but the case then becomes the weak link.

Do you have any concerns about the 231 holding up to the extra power? I'm doing a similar engine/trans swap and am debating between the 231 and standard JK 241 or 241c. I know you can do a 6 gear planetary and wide chain for the 231, but the case then becomes the weak link.

The 3 planetary is rated for something like 600ftlb of torque. So no issues there unless you like bouncing up rocks. The case only breaks for 2 reasons... Lack of front drive shaft maintenance or improper front drive shaft length. Neither will be an issue for me. I may eventually upgrade too an Atlas just for the versatility.

If powered by a few you decide to ‘race’ at stop light in Jan, lose control on snow pack, and hit pole it does test the limits of a np231. But may well be that front driveshaft was simply to long for that given application

The 3 planetary is rated for something like 600ftlb of torque. So no issues there unless you like bouncing up rocks. The case only breaks for 2 reasons... Lack of front drive shaft maintenance or improper front drive shaft length. Neither will be an issue for me. I may eventually upgrade too an Atlas just for the versatility.

Awesome. Thank you. From what I've read some people beat them for years with no issue, and others keep breaking them. Seems like the people breaking them have a drive shaft issue. Hopefully you could show which input shaft, adapter and clocking ring you use when that time comes. I have an idea, but it would be great to see how it all comes together. Sweet build by the way. Read the whole thing over the last couple days.

Awesome. Thank you. From what I've read some people beat them for years with no issue, and others keep breaking them. Seems like the people breaking them have a drive shaft issue. Hopefully you could show which input shaft, adapter and clocking ring you use when that time comes. I have an idea, but it would be great to see how it all comes together. Sweet build by the way. Read the whole thing over the last couple days.

Thanks!

Brianj5600

TJ Expert

The transfercase will see way more than 600 ft/lb. I could see a 231 failing behind a 6l80 with a 4.03 first gear and a little over 300 lb/ft of torque not counting torque multiplication by the torque converter.The 3 planetary is rated for something like 600ftlb of torque. So no issues there unless you like bouncing up rocks. The case only breaks for 2 reasons... Lack of front drive shaft maintenance or improper front drive shaft length. Neither will be an issue for me. I may eventually upgrade too an Atlas just for the versatility.

https://www.motortrend.com/how-to/ccrp-0310-torque-converters/

guess I'll start saving for an atlas

Might check with them on how long it takes to get one built. Took a few months for mine and they contacted me just before they build it for payment.

T

TRE3TOP

Guest

From what I’ve seen they tend to break when the chain gets stretched and not replaced and then get beat on… but I would probably still be thinking about an atlas at some point in your case(pun intended)

guess I'll start saving for an atlas

https://www.novak-adapt.com/knowledge/transfer-cases/np231

So Novak's website says that the HD version (6 gear planetary, SYE and possibly wide chain) will handle up to 2,900ft/lbs, and the standard is 1600-1900. I just called Novak to see what the tech department would say and he said no issues until about 500ft/lbs at the crank with the 6L80. It all looks good on paper, I was just looking for some real world experience. I wonder if any of the stroker or supercharged guys have had any issues?

5632

Love me some Target!!!

Brianj5600

TJ Expert

That's great news! Especially after all that time cleaning and painting the 231.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Pretty, but not as sexy as an Atlas.