Hearing that's it's flexing for you doesn't give me a warm fuzzy on the weight. Definitely going to keep it to a minimum. I did just pick this up to install up there to remove and store my hard top. It'll probably be the last weight I add to it that isn't an empty box.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to / in your garage / shop today?

- Thread starter Zorba

- Start date

Worked on my TJ!!!!!!

Relocate the locker pumps, wire them in, plump them in.

Pictures tomorrow!!!!!

Well here is one, and yes I realize the switches are not even. Due to other wiring behind the cover I had to offset them.

Relocate the locker pumps, wire them in, plump them in.

Pictures tomorrow!!!!!

Well here is one, and yes I realize the switches are not even. Due to other wiring behind the cover I had to offset them.

Hearing that's it's flexing for you doesn't give me a warm fuzzy on the weight. Definitely going to keep it to a minimum. I did just pick this up to install up there to remove and store my hard top. It'll probably be the last weight I add to it that isn't an empty box.

View attachment 497831

So trying to figure out how I'll mount this. I see lots of people using a metal rail presumably so they can move it around, but mine will only ever be used for the TJ hard top in one place via a hole in the drywall ceiling. Would it be acceptable to mount it to a 2x4 turned on edge sitting on top of and running perpendicular to the ceiling trusses?

Made some more progress, finished upper shelf above bench and added lighting. depth of shelf is built shallow enough to clear anything id clamp to the vise vertically if I need the height for something. gonna pop in another ceiling light in the workbench area though now that the ceiling fluorescent fixture is gone.

here's my truss blocking for my 3/8 all thread. For some reason I was under the impression the trusses were 16" on center which I found out to be incorrect after cutting all my 2x4's. you can see they are sitting roughly 3/4" each side on top of the bottom chord... which is sketchy so atop of my workbench shelf I have longer blocking pre-drilled and ready to swap out likely this weekend.

here's my truss blocking for my 3/8 all thread. For some reason I was under the impression the trusses were 16" on center which I found out to be incorrect after cutting all my 2x4's. you can see they are sitting roughly 3/4" each side on top of the bottom chord... which is sketchy so atop of my workbench shelf I have longer blocking pre-drilled and ready to swap out likely this weekend.

So trying to figure out how I'll mount this. I see lots of people using a metal rail presumably so they can move it around, but mine will only ever be used for the TJ hard top in one place via a hole in the drywall ceiling. Would it be acceptable to mount it to a 2x4 turned on edge sitting on top of and running perpendicular to the ceiling trusses?

not familiar with the mounting of the hoist so your mileage may vary. assuming it just lags to wherever its placed..

id sandwich the ceiling in the garage and floor in the attic with a 2x8 or 2x10 then bolt the 2 boards together with some long carriage head bolts or threaded rod cut into foot long sections with a nylock nut or doubled up standard nuts (creating a lock nut). possibly double up the attic side for the day you decide the hoist looks nice to lift something your not intending on lifting today. additionally id bolt the hoist up similar to how im describing with long carriage head bolts rather than lags just into the ceiling board only.

a 10' stick of 3/8 threaded rod goes for ~$12 at depot if your factoring price if the carriage head bolts come out to be a bit pricey. threaded rod weight capacity comes out to be about 400lbs at a minimum and goes upwards of 2k lbs depending on what metal quality you buy.

Last edited:

So trying to figure out how I'll mount this. I see lots of people using a metal rail presumably so they can move it around, but mine will only ever be used for the TJ hard top in one place via a hole in the drywall ceiling. Would it be acceptable to mount it to a 2x4 turned on edge sitting on top of and running perpendicular to the ceiling trusses?

I used a couple sticks of unistrut laid across the top of a few of the ceiling joists to distribute the load.

Bolted my hoist to the ceiling with bolts that tied into the unistrut.

Hearing that's it's flexing for you doesn't give me a warm fuzzy on the weight. Definitely going to keep it to a minimum. I did just pick this up to install up there to remove and store my hard top. It'll probably be the last weight I add to it that isn't an empty box.

View attachment 497831

My shop is 24x45 with trusses on 24" centers. I threw some osb down the center like you did and while I've probably got more weight up there than I should, I've had no problems. As long as you spread it out and don't pile 800lbs in one 3'x3' spot, you'll probably be ok

I picked up a HF 5 drawer service cart with a 25% coupon a couple of week ago and still have not figured out how I want to set it up.

Todays project was trimming down an electrostatic furnace filter 1/2” in all directions so it will fit in the furnace at one of my rentals. Original filter says 16x25x5 and owners manual says the same but the true Lennox required size is 15.5x25.5x4.5. They want twice the price for their filter. I’m not set up to bend sheetmetal so it’s not pretty but it fits and works.

View attachment 398063

View attachment 398064

View attachment 398065

We must be twins. Also got one using my “Manager misses you” 25% off anything in the store coupon that I get every so often. HVAC unit has proprietary filter size. Saved $$$ modifying my own.

I have an intimidating older neighbor. She came over yesterday and asked if I wanted her dad's old work bench and I didn't have the strength to say no.

It was wobbly and held together with nails. I sunk a few construction screws in various places to try and sturdy it which really helped. I think it'll work just fine for some lighter projects.

It was wobbly and held together with nails. I sunk a few construction screws in various places to try and sturdy it which really helped. I think it'll work just fine for some lighter projects.

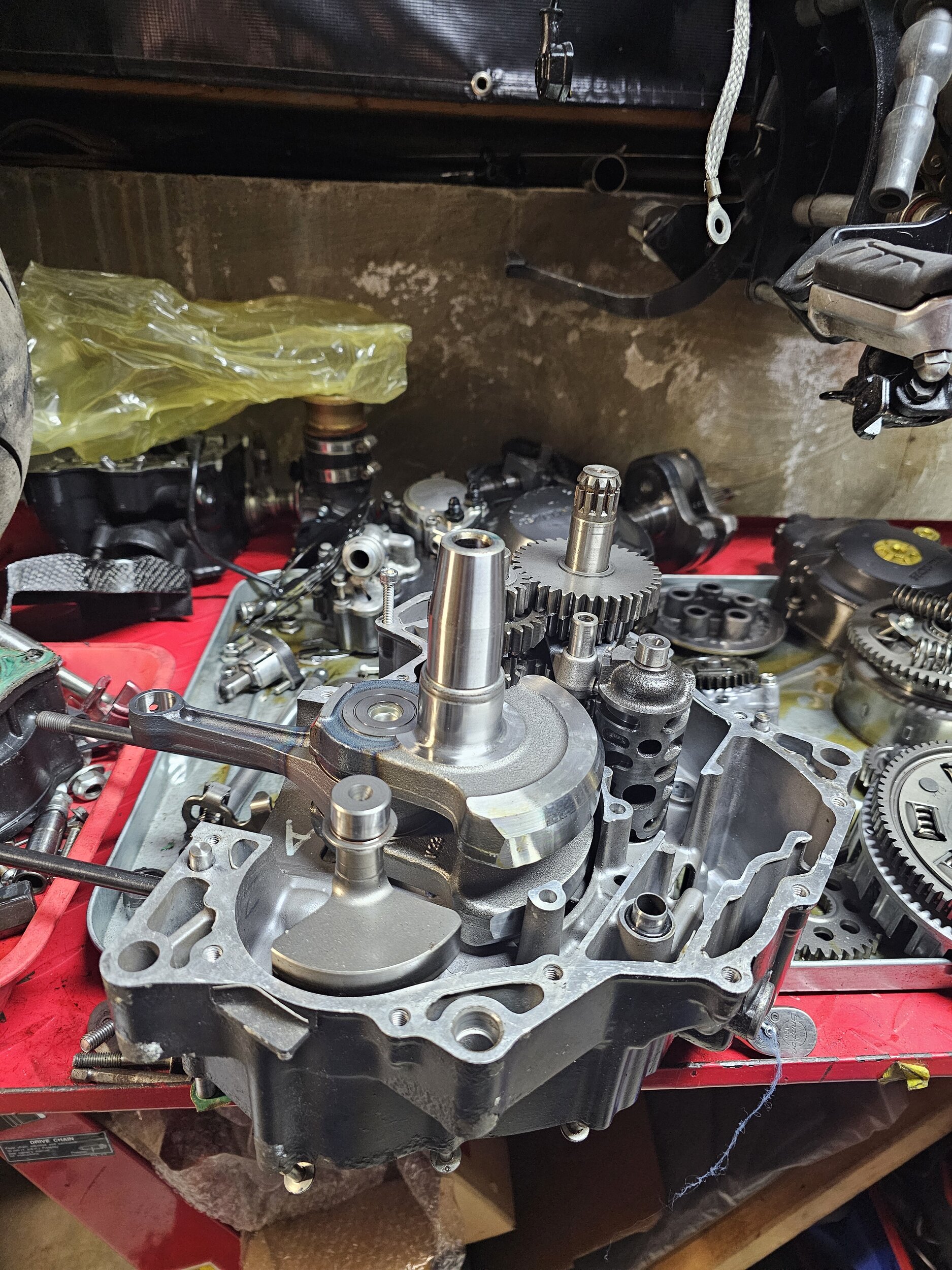

Last night I worked on my motor for the grom, I refer to this as a oil change, but my friends understand this as a motor rebuild

Did some head work last night and got rid of some parts that arent up to snuff...

I have an intimidating older neighbor. She came over yesterday and asked if I wanted her dad's old work bench and I didn't have the strength to say no.

View attachment 504322

It was wobbly and held together with nails. I sunk a few construction screws in various places to try and sturdy it which really helped. I think it'll work just fine for some lighter projects.

I was given a wobbly one just like that with 2x6 top. If you add a diagonal brace across the back, or just some plywood in a couple places, it will firm it up nicely. I have since covered mine with some stainless that was given to me by my wife's friend who was pissed off at her husband for leaving her. I got all his heavy extension cords too.

I was given a wobbly one just like that with 2x6 top. If you add a diagonal brace across the back, or just some plywood in a couple places, it will firm it up nicely. I have since covered mine with some stainless that was given to me by my wife's friend who was pissed off at her husband for leaving her. I got all his heavy extension cords too.

My plan is to replace the bottom two boards with a single sheet of plywood, and I may add another brace underneath the table top. If I can do everything I want to do in the garage this summer (insulate and sheetrock) I may also find a way to secure it to the wall.

Cut another batch of decals for a buddy's TJ. This is probably the 30th batch I've cut in the last 3 weeks between testing sizes and final products. If only the vinyl would weed itself, this wouldn't be so bad.

Son of a..... No. It isn't. I don't know how I hadn't caught that. I bought two different files that have it the same way. I guess I'll need to go in and modify that "R" and then cut some replacementsIs the second R in WRANGLER really supposed to be different than the first? It looks truncated to my eye.

Might have to get you to cut me some 4.7L badges

Find a file or pic of what you want, pick a color, and I'd be happy to. If you can't find what style you want, play around with fonts and let me know what you like best.

Yes. And a Stroker badge in the Sport font is nice, I think.Might have to get you to cut me some 4.7L badges

I like all stock looking stuff. Just correct numbers, and it's a 4.7L now.