Already have a new one installed on the new pump.Do yourself a favor and replace that inlet pipe as well, she looks to be rusting out from the inside.

https://www.amazon.com/gp/product/B001C6JCU0?tag=wranglerorg-20

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your TJ today?

- Thread starter LJRubiconGuy

- Start date

Already have a new one installed on the new pump.

Even better, install an aluminum NPT-to- 5/8” barb fitting. This will make future replacements much easier. I learned of the alternative fitting idea from others.

I believe this is what I installed.

Add some 5/8” heater hose coupled with this Barb fitting.

Last edited:

Well, crap. They won't be here before I need it back together. Probably will do that this spring when I change the heater core.Even better, install an aluminum NPT-to- 5/8” barb fitting. This will make future replacements much easier. I learned of this option from others.

I believe this is what I installed.

Join it to some extended 5/8” heater hose with this Barb fitting.

Well, crap. They won't be here before I need it back together.

I know that feeling all too well…needing the same fittings delayed a drive to CA this past summer.

I chose aluminum over stainless steel or brass fittings to avoid issues with galvanic corrosion.

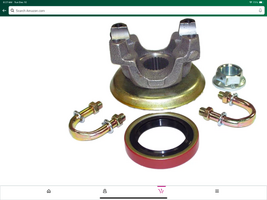

I failed to mention, don’t forget to get some clamps. Sorry about that. According to my purchases, these might be what I’m using.

I cleaned up burrs on carrier housing, degreased with wd40 specialist degreaser not dry out seals. Put back together with gear oil. Going to leave old carrier bearings on for pinion set up. Did get Vevor clam shell puller. Yoke puller should be here soon. I tried drift pin method again today to remove pinion, no avail.

Carrier bearings and new ring bolts coming in early this week. Yes….I am addicted to tools.

Got the last fender on. I just have to modify my RockHard sliders to fit around the front fenders. I'm very impressed with his the first and finish is on these fenders. The only thing I had to do was bend the edge at the upper shock mount to clear the stud. Other than that, everything fit perfectly.

Also got the water pump off and ready for a new one tomorrow afternoon. This looks to be the original one; replacing it with a NOS Mopar one.

View attachment 578085

View attachment 578086

View attachment 578087

View attachment 578088

Are those horns OE?

Drove BB to work today, runs great and drives great.

New control arms are quiet and no vibes at highway speed!!

We will see how the Metalcloak arms hold up over the next year!!!!

Probably try and hit Coalmont OHV Park and Estill Forks and maybe Stoney Lonesome after the first of the year just to see how they do.

New control arms are quiet and no vibes at highway speed!!

We will see how the Metalcloak arms hold up over the next year!!!!

Probably try and hit Coalmont OHV Park and Estill Forks and maybe Stoney Lonesome after the first of the year just to see how they do.

MountaineerTom

LJ Enthusiast, Retired USAF Weapons Loader

Supporting Member

Ride of the Month Winner

Yes they are. Thank him for his service. Hopefully he’s working as a government contractor now?

Thank you. Same to your son.

Yes, I was worried when he decided to get out in 2020 but he had a contract electrician job lined up within a week. He was an electricians mate. He’s since switch jobs again and has a GS level job.

Last edited:

IIRCI know that feeling all too well…needing the same fittings delayed a drive to CA this past summer.

I chose aluminum over stainless steel or brass fittings to avoid issues with galvanic corrosion.

I failed to mention, don’t forget to get some clamps. Sorry about that. According to my purchases, these might be what I’m using.

If you're using GO5 HOAT coolant you shouldn't have that problem

FIGHTS

HYBRID ORGANIC ACID TECHNOLOGY FIGHTS RUST, SCALE & CORROSION while protecting all cooling system metals (including aluminum)

https://shop.valvolineglobal.com/pr...Vo-odlJLUT8IRCc50Y9rdvR62tI83JOge0PuJh7Wj_Xl_

yesterday took the stock wheels i painted off the jeep and bolted on the Hubs i painted to match the jeeps paint

we've got 4inches of white stuff coming this morning so im gonna be playing in the snow

we've got 4inches of white stuff coming this morning so im gonna be playing in the snow

yesterday took the stock wheels i painted off the jeep and bolted on the Hubs i painted to match the jeeps paint

we've got 4inches of white stuff coming this morning so im gonna be playing in the snow

View attachment 578191

View attachment 578192

View attachment 578193

Must be a Hobbit fan.

IIRC

If you're using GO5 HOAT coolant you shouldn't have that problem

View attachment 578167

FIGHTS

HYBRID ORGANIC ACID TECHNOLOGY FIGHTS RUST, SCALE & CORROSION while protecting all cooling system metals (including aluminum)

https://shop.valvolineglobal.com/pr...Vo-odlJLUT8IRCc50Y9rdvR62tI83JOge0PuJh7Wj_Xl_

I only run G05, but it doesn't eliminate rust or galvanic corrosion in our rigs with an iron block.

Even with distilled water and G05 coolant, electrolysis will take place because the rust on the surfaces of the iron block contains charged particles of iron that enters the solution (creating an electrolyte) and reacts with the dissimilarly composed radiator, water pump, and heater core.

This means that fastening an incompatible fitting to the aluminum water pump will likely result in galvanic corrosion. I prefer to employ the minimal effort to prevent that from happening.

Do you trust the marketing that you highlighted above enough to install incompatible fittings simply because you are using G05?

Last edited:

I guess since I haven't had a need to modify things in my cooling system, I'll probably never have to worry about that. But it's not just Valvoline's marketing that makes the claim that it stops corrosion in cooling systems with dissimilar metals.I only run G05, but it doesn't eliminate rust or galvanic corrosion in our rigs with an iron block.

Even with distilled water and G05 coolant, electrolysis will take place because the rust on the surfaces of the iron block contains charged particles of iron that enters the solution (creating an electrolyte) and reacts with the dissimilarly composed radiator, water pump, and heater core.

This means that fastening an incompatible fitting to aluminum water pump will likely result in galvanic corrosion. I prefer to employ the minimal effort to prevent that from happening.

Do you trust the marketing that you highlighted above enough to install incompatible fittings simply because you are using G05?

Now that may not account for physically attaching dissimilar metals. So... yep it's definitely best to use similar metals.

Drove BB to work today, runs great and drives great.

New control arms are quiet and no vibes at highway speed!!

We will see how the Metalcloak arms hold up over the next year!!!!

Probably try and hit Coalmont OHV Park and Estill Forks and maybe Stoney Lonesome after the first of the year just to see how they do.

Go ahead and order a set of the snap ring pliers with the interchangable ends. If you wheel regularly those joints don't last as long. But they are easy to replace with the right tools.

Also when MetalCloak has a sale stock up on replacement bushings. That is what I did

But it's not just Valvoline's marketing that makes the claim that it stops corrosion in cooling systems with dissimilar metals.

It doesn't stop corrosion...nor does it make that claim.

If the label said "slows corrosion down better than many other alternative options" you might not buy it. Instead, they use words like "fights" and "protects", which provides comfort through carefully executed marketing.

You interpreted that label to mean G05 "stops corrosion" when it does not (for reasons that have already bean explained). You probably see right through marketing in other instances that falls in the "mere puffery" category in sales, and the marketing you highlighted from Valvoline is no different. They simply dumbed it down for the average consumer.

Must be a Hobbit fan.

YUP

That and many other stuff ive "Come Back From"

It could be a bad ECM. The voltage regulator is built into the ECM.

Yeah, I am hoping it was a fluke. I did get the opportunity to check everything out Sunday. All connections were tight and clean. I've put maybe 50 miles on it since that happened and so far so good.

I know that feeling all too well…needing the same fittings delayed a drive to CA this past summer.

I chose aluminum over stainless steel or brass fittings to avoid issues with galvanic corrosion.

I failed to mention, don’t forget to get some clamps. Sorry about that. According to my purchases, these might be what I’m using.

Maybe you should put some sacrificial zincs on your rudder...