The manual Swayloc is about as simple as it could get. The real question is whether you want a dual rate. i.e. Factory like on the road, when locked, and Antirock like, when in off-road mode. FWIW, the Swayloc has the same type adjustment holes, in off-road mode, like the Antirock.Thank you so much @Irun I'm checking out all the posts now. I liked the UCF rear bumper because the hitch looked functional for what I'm going to try using it for.

It's going to take me a while to get through the Antirock vs Swayloc thread. My gut reactions is still to go AntiRock just for simplicity (Says the guy that is running a turbo diesel with a water to air intercooler setup). I could go purely manual from what I'm reading on their site though having a remote actuated setup would be awesome as well.

Thanks

Grant

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a diesel powered RHD TJ Wrangler (Picture Heavy)

- Thread starter RustyAutoholicGuy

- Start date

The answer to your question @Irun is probably yes. I'm reading through Mr. Bills thread now. All of this stuff is a monumental shift in how I'm approaching my TJ. I really originally was going for a daily with light weekend wheeling and now I'm going for capable light weight diesel overlander.The manual Swayloc is about as simple as it could get. The real question is whether you want a dual rate. i.e. Factory like on the road, when locked, and Antirock like, when in off-road mode. FWIW, the Swayloc has the same type adjustment holes, in off-road mode, like the Antirock.

I'm still scrolling through your thread as well. The UCF rear bumper looks awesome. That has sold me on getting that bumper combo for my TJ.

Okay @Alex01 and @Irun after reading @Mr. Bills thread about his experience with the swaybars on his Wrangler and y'alls recommendations I'm going to go with the SwayLoc instead.

Thank you again so much for your feedback, this is the kind of stuff I was hoping to get feedback on!

Thanks

Grant

Thank you again so much for your feedback, this is the kind of stuff I was hoping to get feedback on!

Thanks

Grant

Hey TJers,

While browsing Facebook last week I came across this used Savvy Aluminum Fuel Tank Skid Plate for sale not far from my home and decided it would be a nice upgrade to have for my TJ Wrangler.

Since I already have a 1.25" body lift on my Jeep I'll be able to raise the tank 2" and gain some additional ground clearance. The other advantage to swapping out the skid plates for the fuel tank is it gives me a perfect opportunity to adjust the fuel sending unit arm in the tank.

When I installed the Carter lift pump I didn't set the arm on the fuel sending unit correctly so my fuel gauge has never been accurate. However after removing the tank I decided it would be a perfect time to install the GenRight Fuel Tank Access Panel in the back of my TJ.

I realized there is a bit of a divided opinion on the access panel here on the forums, however it makes sense to me for my setup, especially considering that I'm not running the factory fuel pump. Also having this access panel will allow me to make adjustments to the fuel level sending unit without dropping the tank but also when I'm out wheeling or overlanding, I can bring a spare pump with me and replace it if the lift pump in my tanks dies on me for whatever reason.

Here is the video if you want to watch it:

Let me know what you think!

Thanks

Grant

While browsing Facebook last week I came across this used Savvy Aluminum Fuel Tank Skid Plate for sale not far from my home and decided it would be a nice upgrade to have for my TJ Wrangler.

Since I already have a 1.25" body lift on my Jeep I'll be able to raise the tank 2" and gain some additional ground clearance. The other advantage to swapping out the skid plates for the fuel tank is it gives me a perfect opportunity to adjust the fuel sending unit arm in the tank.

When I installed the Carter lift pump I didn't set the arm on the fuel sending unit correctly so my fuel gauge has never been accurate. However after removing the tank I decided it would be a perfect time to install the GenRight Fuel Tank Access Panel in the back of my TJ.

I realized there is a bit of a divided opinion on the access panel here on the forums, however it makes sense to me for my setup, especially considering that I'm not running the factory fuel pump. Also having this access panel will allow me to make adjustments to the fuel level sending unit without dropping the tank but also when I'm out wheeling or overlanding, I can bring a spare pump with me and replace it if the lift pump in my tanks dies on me for whatever reason.

Here is the video if you want to watch it:

Let me know what you think!

Thanks

Grant

The access panel is a great idea. If you run a carpet nobody would ever know it existed.

I thought the gts only raised the tank 1.25" but since could be wrong. I never measured.

I thought the gts only raised the tank 1.25" but since could be wrong. I never measured.

The access panel is a great idea. If you run a carpet nobody would ever know it existed.

I thought the gts only raised the tank 1.25" but since could be wrong. I never measured.

@Alex01 I'm glad you think the access panel is a good idea, when I did a search on the forum after I bought it I debated not mentioning that I was going to install it on my TJ

As for my skid plate, it has two different setting on it that I can adjust, one for 1" lift and the second for a 2" lift.

-Grant

Hey TJers,

SO while I'm still wanting for my one adapter so I can wrap up my project, COVID has just really delayed everything to annoying levels, I decided to go ahead and swap out the shocks on my Wrangler. I wanted to wait until my TJ was running again but I had the parts and I figured having the rear fuel tank out would make my life easier which it did.

Doing the front took me literally minutes, I didn't have to fight the top or bottom fasteners which was a relief.

I got really lucky with the rear shocks as well, I didn't have to fight any corrosion with the rear upper shock bolts which I know TJs are prone to having issues with.

Right now the shocks have raised my TJ a solid inch I would say but I'm also expecting the shocks to settle once I get some miles on them as well.

Another thing off my list and the waiting game continues, but while that happens I'll install the rear fuel access panel, and start putting the interior back together as well.

Here is the video if you're interested:

Thanks

Grant

SO while I'm still wanting for my one adapter so I can wrap up my project, COVID has just really delayed everything to annoying levels, I decided to go ahead and swap out the shocks on my Wrangler. I wanted to wait until my TJ was running again but I had the parts and I figured having the rear fuel tank out would make my life easier which it did.

Doing the front took me literally minutes, I didn't have to fight the top or bottom fasteners which was a relief.

I got really lucky with the rear shocks as well, I didn't have to fight any corrosion with the rear upper shock bolts which I know TJs are prone to having issues with.

Right now the shocks have raised my TJ a solid inch I would say but I'm also expecting the shocks to settle once I get some miles on them as well.

Another thing off my list and the waiting game continues, but while that happens I'll install the rear fuel access panel, and start putting the interior back together as well.

Here is the video if you're interested:

Thanks

Grant

https://wranglertjforum.com/attachments/yqsu2ae-jpg.234666/The access panel is a great idea. If you run a carpet nobody would ever know it existed.

I thought the gts only raised the tank 1.25" but since could be wrong. I never measured.

Today was suppose to be a victory . . . and yet it was setback instead

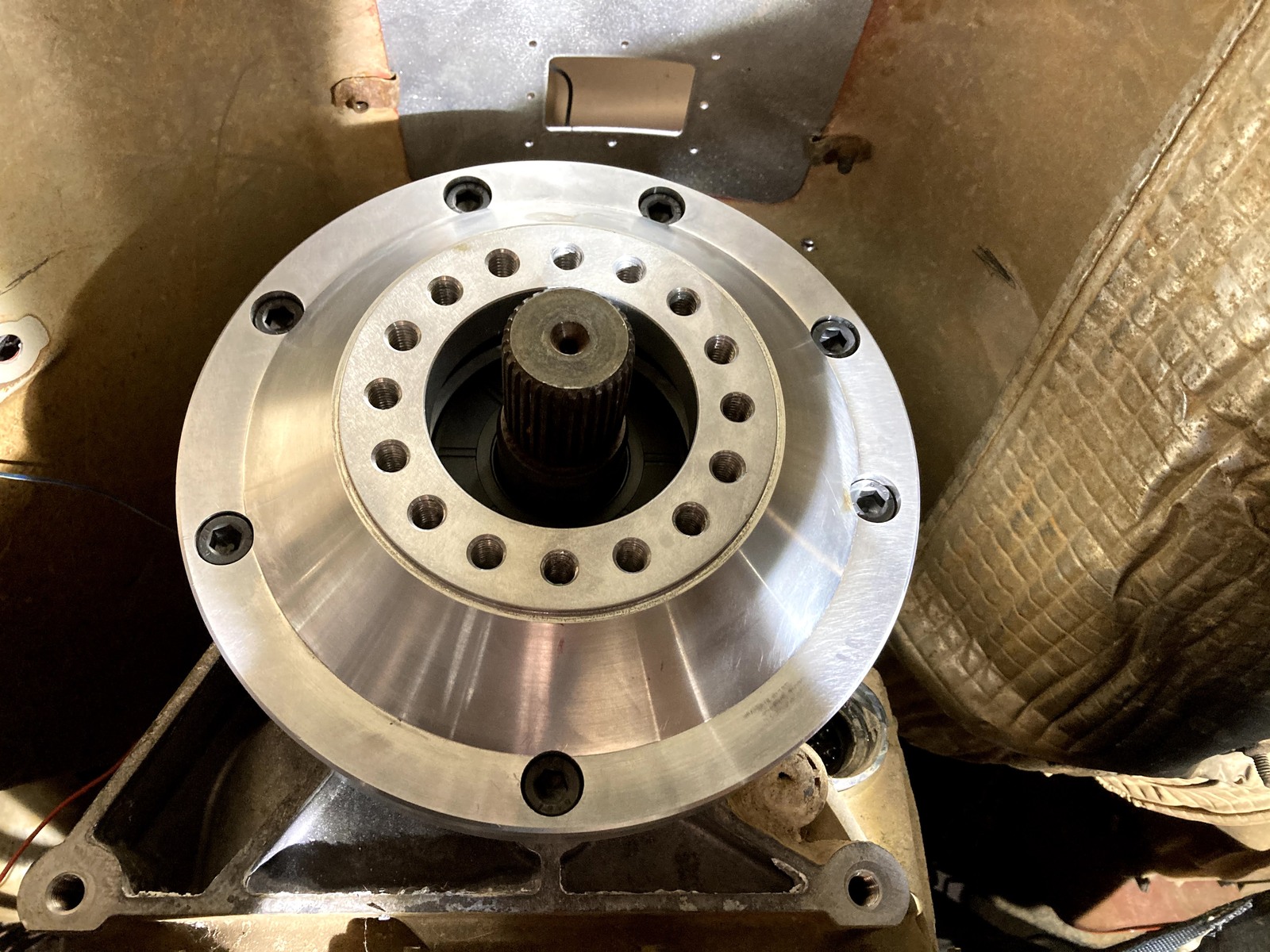

I finally got my Ford 6r80 transmission to NP231 adapter in. It looks great and the two piece design with the 3 mounting positions along with the multiple mounting points between the two halves of the adapter will allow me to clock the adapter in any position that I want it to be in.

NP231 Side:

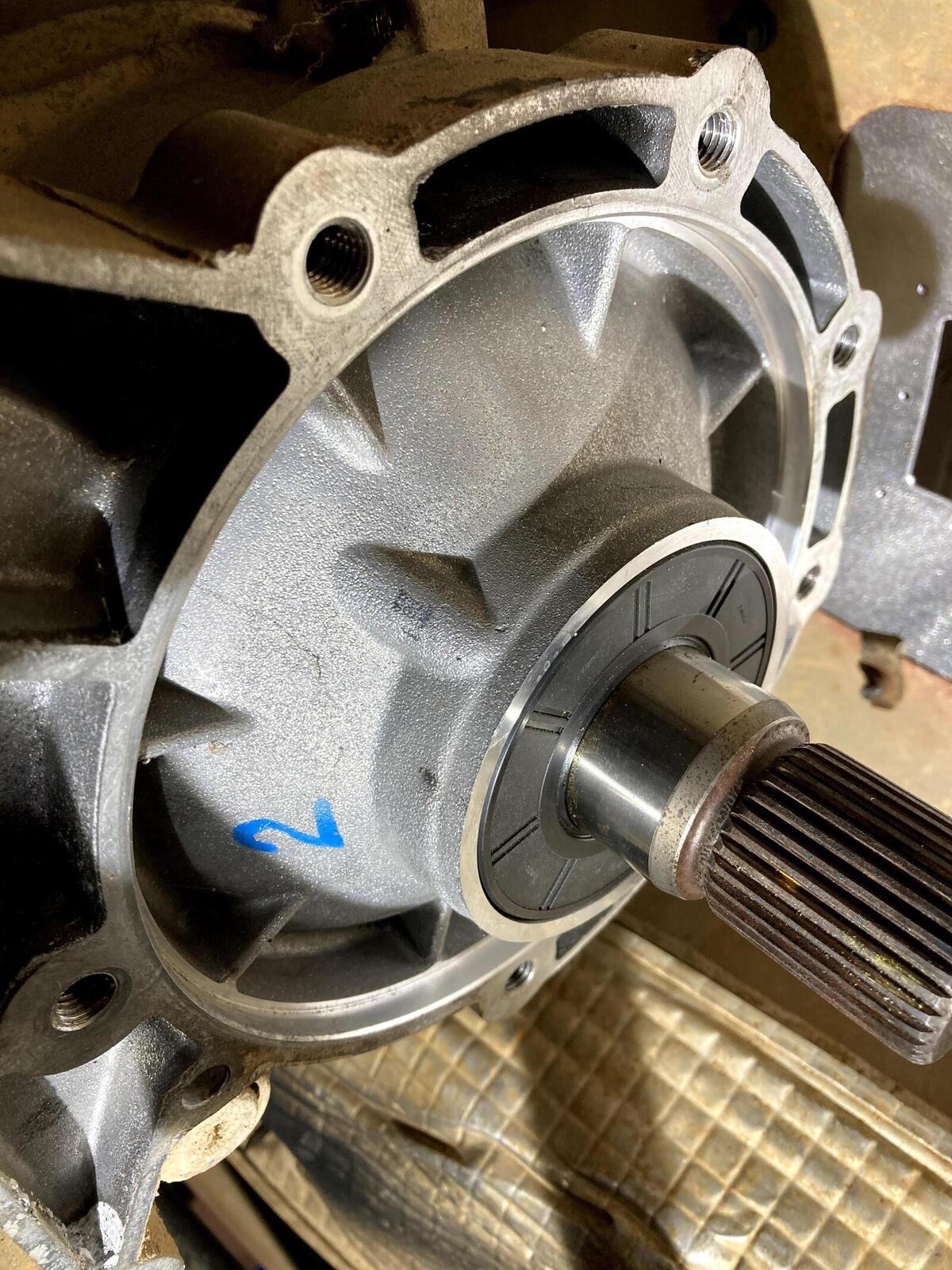

6r80 Side:

This is the life you live when you get custom parts made and your machinist is on the opposite coast from you and a pandemic screws up material delivery as well.

Lets start with the NP231 side of the adapter . . . this one is on me unfortunately. I didn't measure the size of the bearing retainer cap for the NP231 correctly and it's not allowing the adapter to seat flush against the transfer case body.

Now onto the Ford 6r80 side of the transmission adapter and again this one is also my fault. To create the Kubota engine to transmission adapter I had to send a transmission to KubotaSwappers as a reference, I bought a busted 2011 Ford 6r80 on eBay that had free shipping and had it mailed to KubotaSwappers.

He used that same transmission to make the Ford 6r80 to NP231 adapter. Unbenonst to either of us at the time, my 2014 model 6r80 has a slightly different casting around the output shaft housing so it's not sitting flush against the transmission case.

Oddly enough this one is easier to fix as I just have to take a die grinder and remove some of the material on the adapter where it's currently hitting the housing around the output shaft on the Ford 6r80 transmission.

At the end of the day both of the problems are solvable. I took the bearing housing off the NP231 along with the transfer case side of the adapter to the only machine shop I could find where I live and I should have it fixed and back sometime next week, around Tuesday or Wednesday.

As for the transmission side of the adapter I'm going to start slowly removing material from the adapter so it clears the housing around the output shaft of the transmission until I can get it to sit flush with the transmission case.

Again not the end of the world but I had hopes of ordering driveshafts tomorrow and possibly getting my TJ running again, admittedly without driveshafts, this weekend, that will now be postponed another two weeks since I have my kids the following weekend.

I'm getting there, the goal now is to have it all back together before the end of April and on the trails no latter than May but as always I fully except some other issues that I haven't for seen to pop up in the near future as well.

-Grant

I finally got my Ford 6r80 transmission to NP231 adapter in. It looks great and the two piece design with the 3 mounting positions along with the multiple mounting points between the two halves of the adapter will allow me to clock the adapter in any position that I want it to be in.

NP231 Side:

6r80 Side:

This is the life you live when you get custom parts made and your machinist is on the opposite coast from you and a pandemic screws up material delivery as well.

Lets start with the NP231 side of the adapter . . . this one is on me unfortunately. I didn't measure the size of the bearing retainer cap for the NP231 correctly and it's not allowing the adapter to seat flush against the transfer case body.

Now onto the Ford 6r80 side of the transmission adapter and again this one is also my fault. To create the Kubota engine to transmission adapter I had to send a transmission to KubotaSwappers as a reference, I bought a busted 2011 Ford 6r80 on eBay that had free shipping and had it mailed to KubotaSwappers.

He used that same transmission to make the Ford 6r80 to NP231 adapter. Unbenonst to either of us at the time, my 2014 model 6r80 has a slightly different casting around the output shaft housing so it's not sitting flush against the transmission case.

Oddly enough this one is easier to fix as I just have to take a die grinder and remove some of the material on the adapter where it's currently hitting the housing around the output shaft on the Ford 6r80 transmission.

At the end of the day both of the problems are solvable. I took the bearing housing off the NP231 along with the transfer case side of the adapter to the only machine shop I could find where I live and I should have it fixed and back sometime next week, around Tuesday or Wednesday.

As for the transmission side of the adapter I'm going to start slowly removing material from the adapter so it clears the housing around the output shaft of the transmission until I can get it to sit flush with the transmission case.

Again not the end of the world but I had hopes of ordering driveshafts tomorrow and possibly getting my TJ running again, admittedly without driveshafts, this weekend, that will now be postponed another two weeks since I have my kids the following weekend.

I'm getting there, the goal now is to have it all back together before the end of April and on the trails no latter than May but as always I fully except some other issues that I haven't for seen to pop up in the near future as well.

-Grant

Well today has been the opposite Tuesday! I got my transfer case side of the adapter back from the machinist 5 days earlier than expected this morning and already did a quick test fit:

As you can see the adapter is now sitting flush against the transfer case and it's perfectly centered to the input shaft. Major win!!!

Also I've figured out where my clearance issues are on the transmission side of the adapter which I mentioned in my last post, but I was able to see the marking on the adapter itself and on the transmission as seen below:

Talked to KubotaSwappers this morning and he told me how to mark the adapter with a quarter of all things to give me a guide on what material I need to remove to make it fit on the back of my transmission.

This puts me back on schedule for trying to get my Wrangler running again this weekend possibly, I won't have driveshafts but I'll be able to start my Wrangler which I haven't done since October.

I just need to do the following:

Anyway back to the grind.

-Grant

As you can see the adapter is now sitting flush against the transfer case and it's perfectly centered to the input shaft. Major win!!!

Also I've figured out where my clearance issues are on the transmission side of the adapter which I mentioned in my last post, but I was able to see the marking on the adapter itself and on the transmission as seen below:

Talked to KubotaSwappers this morning and he told me how to mark the adapter with a quarter of all things to give me a guide on what material I need to remove to make it fit on the back of my transmission.

This puts me back on schedule for trying to get my Wrangler running again this weekend possibly, I won't have driveshafts but I'll be able to start my Wrangler which I haven't done since October.

I just need to do the following:

- Finish assembling my NP231

- Remove the material from the transmission side of my adapter

- Mount my transfer case to my transmission

- Fabricate a new crossmember for my transmission and transfer case

- Install the Derale transmission cooler and cooling lines for my transmission

- Install the Quick6 TCU and required sensors for my transmission

- Install the transmission shifter

- Install the transfer case shifter

- Install the front grill and cooling for the engine and intercooler

- Install the exhaust

- Wire up the new starter for the transmission

- Install the GenRight Fuel Tank Access Panel

- Install my Fuel Tank

- Measure for new driveshafts

Anyway back to the grind.

-Grant

Grant

What did you end up doing with the eco box? I know it fought you at first but once got it together were you happy with it?

What did you end up doing with the eco box? I know it fought you at first but once got it together were you happy with it?

I still have the eco box and I really do like it as well. Getting it assembled and installed was a bit tricky but it was fantastic to have, if I had the length in my TJ I would put it back in.Grant

What did you end up doing with the eco box? I know it fought you at first but once got it together were you happy with it?

If I ever cut my TJ in half and make a TJ-6 out of my TJ I'll reinstall the doubler for sure!

Hey TJers,

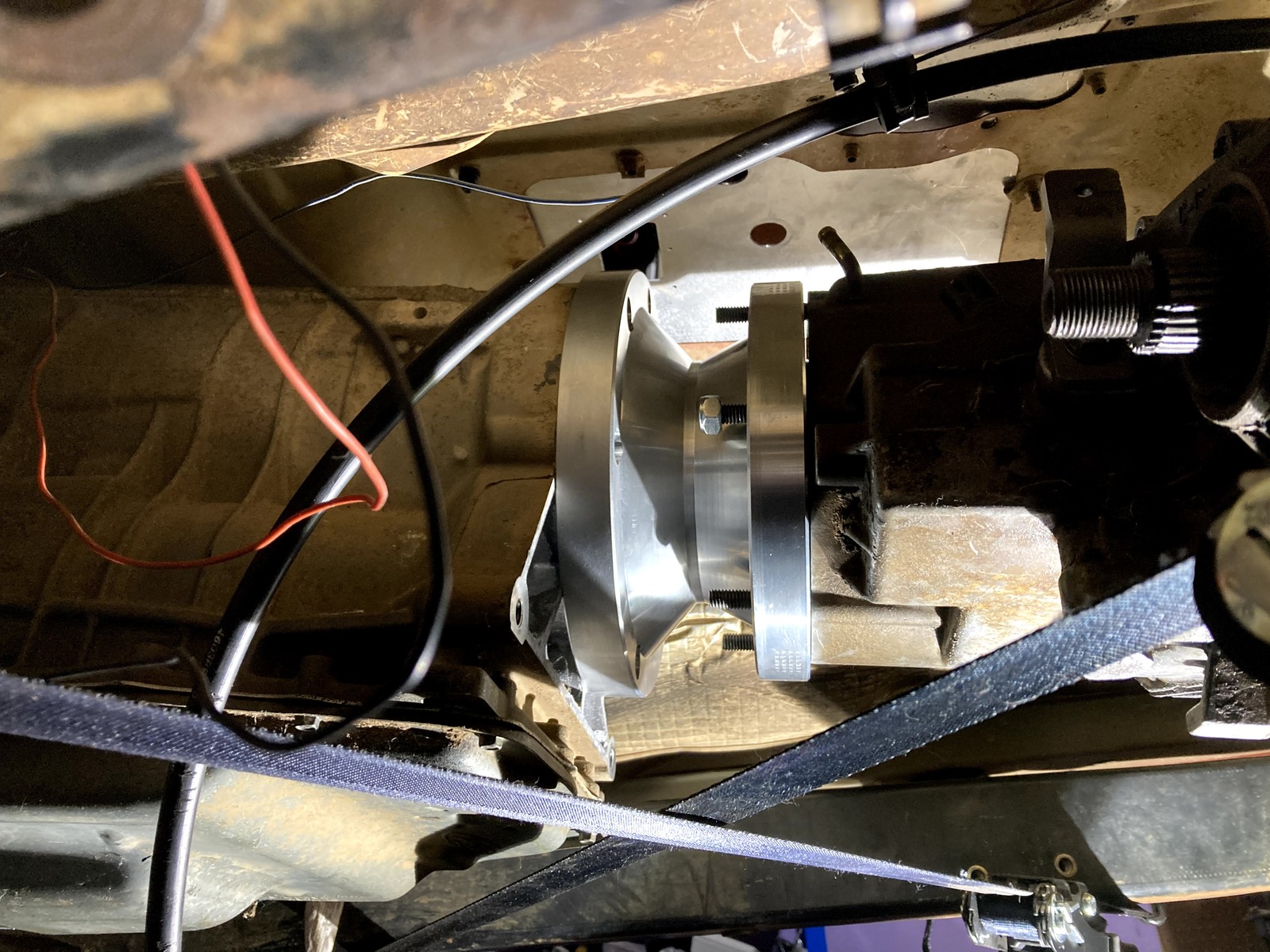

I've got my adapter figured out and installed, now it's just putting the rest of my TJ back together and hopefully getting it running and driving sometime by the end of April or early May at the latest.

So to fix the transmission side of the adapter I ended up grinding a quarter size chunk of aluminum out of the adapter which worked perfectly.

The transfer case side of the adapter was even easier, just took it to a machinist and had them clearance the opening on the adapter to 10/1000ths of an inch to the bearing cap.

I did have to drill out two holes on the transmission side of the adapter because I couldn't get the bolts to go through, I went with one size bigger for the drill bit and it worked perfectly.

With those 3 issues resolved, I finally have my Ford 6r80 attached to my NP231 transfer case. Now I can focus on modifying the crossmember I had originally made for my original driveline.

Making progress, with any luck I'll be driving my TJ starting in a few weeks so I can wheel this summer, fall and winter.

Here is the video if you want to watch it:

Thanks

Grant

I've got my adapter figured out and installed, now it's just putting the rest of my TJ back together and hopefully getting it running and driving sometime by the end of April or early May at the latest.

So to fix the transmission side of the adapter I ended up grinding a quarter size chunk of aluminum out of the adapter which worked perfectly.

The transfer case side of the adapter was even easier, just took it to a machinist and had them clearance the opening on the adapter to 10/1000ths of an inch to the bearing cap.

I did have to drill out two holes on the transmission side of the adapter because I couldn't get the bolts to go through, I went with one size bigger for the drill bit and it worked perfectly.

With those 3 issues resolved, I finally have my Ford 6r80 attached to my NP231 transfer case. Now I can focus on modifying the crossmember I had originally made for my original driveline.

Making progress, with any luck I'll be driving my TJ starting in a few weeks so I can wheel this summer, fall and winter.

Here is the video if you want to watch it:

Thanks

Grant

AidenC

TJ Enthusiast

You're almost there man. I know that transfer case adapter was slowing you down, hopefully its all pretty easy for you here on.

I hope so as well, I have a few unknowns, specifically can I finally cruise at highway speeds reliably and I need to figure out how I'm going to wire up this new TCU for the Ford 6r80 as well!You're almost there man. I know that transfer case adapter was slowing you down, hopefully its all pretty easy for you here on.

I really wish I could have made it to TJ Fest this year but I just need more time to figure out all the kinks and get more seat time both on and off the trails before I feel comfortable traveling 2000 miles cross country to go to Moab!

-Grant

Hey TJers

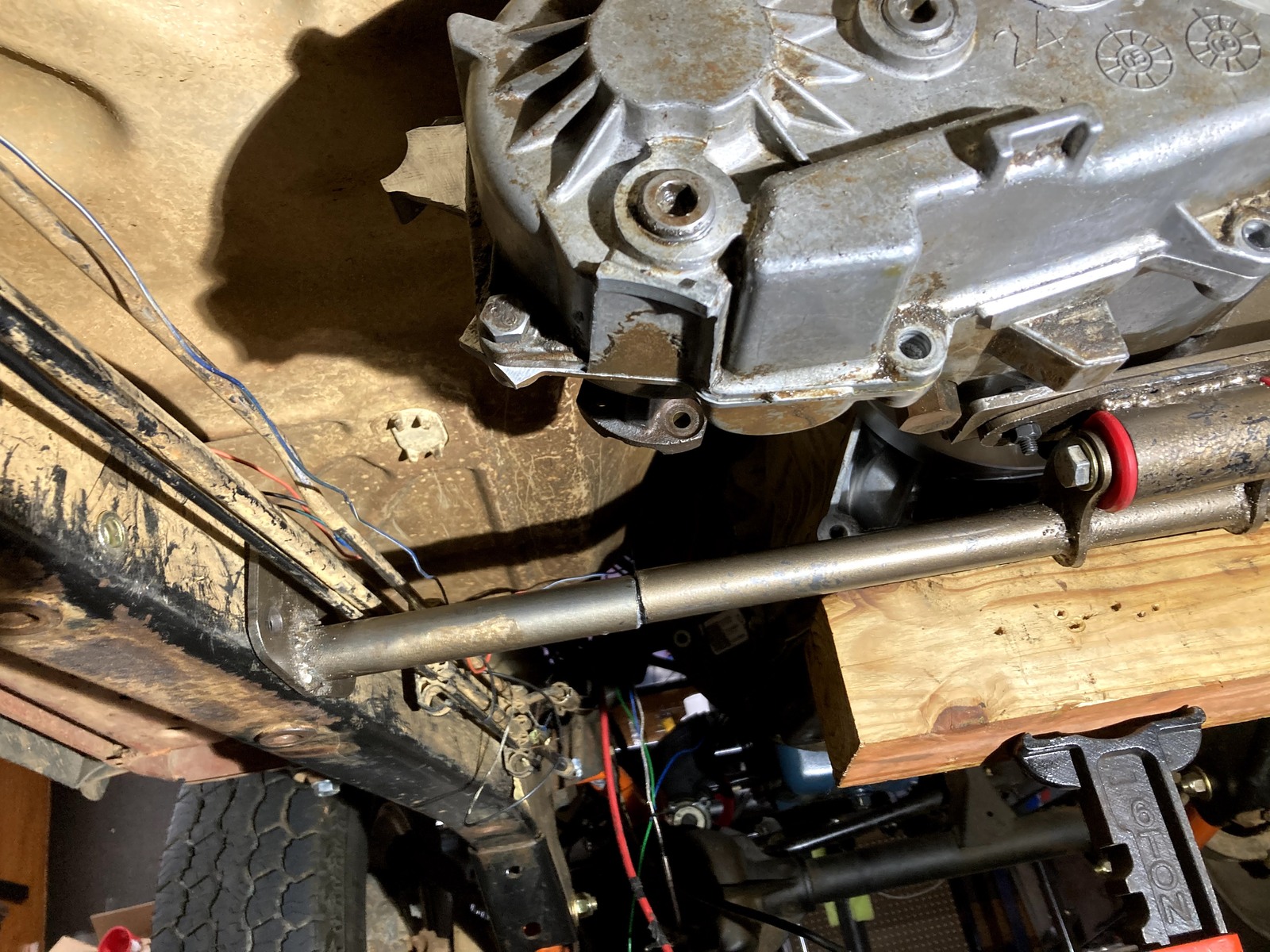

Made some more progress on the transmission swap on my Kubota diesel powered TJ Wrangler. Got my Ford 6r80 automatic to NP231 transfer case crossmember modified and installed this week.

I decided it would be easier to modify the crossmember I had originally made for my diesel swap instead of fabricating another one from scratch. I already had the correct angles for the frame rails and I knew all I needed to do was narrow the length of the bar. Turns out it was a little bit more difficult than that, I kept fighting clearance issues to either transfer case itself or the front driveshaft yoke, though I finally got it sorted it.

Once I figured out where I wanted the crossmember to go, I cut up my original crossmember and used another piece of round tubing to re-enforce the crossmember. I’m sure there are those who could cut and weld the original tubing to be just as strong, but I decided to sleeve the inside of the crossmember with another piece of round tubing to ensure the strength of the crossmember.

The other thing I realized in redoing my crossmember was that I making things that are functional, not pretty. Now that is complete, I can turn my focus onto hooking up the cooling for the transmission and shifts next.

Here is the video if you want to watch it:

Let me know what you think!

Thanks

Grant

Made some more progress on the transmission swap on my Kubota diesel powered TJ Wrangler. Got my Ford 6r80 automatic to NP231 transfer case crossmember modified and installed this week.

I decided it would be easier to modify the crossmember I had originally made for my diesel swap instead of fabricating another one from scratch. I already had the correct angles for the frame rails and I knew all I needed to do was narrow the length of the bar. Turns out it was a little bit more difficult than that, I kept fighting clearance issues to either transfer case itself or the front driveshaft yoke, though I finally got it sorted it.

Once I figured out where I wanted the crossmember to go, I cut up my original crossmember and used another piece of round tubing to re-enforce the crossmember. I’m sure there are those who could cut and weld the original tubing to be just as strong, but I decided to sleeve the inside of the crossmember with another piece of round tubing to ensure the strength of the crossmember.

The other thing I realized in redoing my crossmember was that I making things that are functional, not pretty. Now that is complete, I can turn my focus onto hooking up the cooling for the transmission and shifts next.

Here is the video if you want to watch it:

Let me know what you think!

Thanks

Grant

I found your channel when I was looking for insight on installing control arms. You have a great channel an the tj is awesome!

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Wait... how do shocks affect your ride height unless you have some serious nitrogen charge in there. Shocks are dampers (ie resist motion) the springs will determine your ride height.Right now the shocks have raised my TJ a solid inch I would say but I'm also expecting the shocks to settle once I get some miles on them as well.

Thank you so much! This has been a long and enjoyable build! I'm looking forwarding to seeing what it can do on the trails!I found your channel when I was looking for insight on installing control arms. You have a great channel an the tj is awesome!

Um . . . . yeah I don't know, I'll revisit in the morning after some sleepWait... how do shocks affect your ride height unless you have some serious nitrogen charge in there. Shocks are dampers (ie resist motion) the springs will determine your ride height.

Hey TJers,

After getting a bunch of, mostly, constructive feedback on my welding on my crossmember for my diesel swap TJ Wrangler project in my previous post, I decided to pull the crossmember to fix all my welds. Lesson learned, don’t rush welding. I’m so far behind on this project, in terms of my own timeline, that I rushed both the welding and cleanup of the crossmember.

I also want to address a few of the concerns that were raised in my last post as well.

The first was that the crossmember would bend the first time I dropped onto an obstacle while wheeling. I’m going to be adding skid plates to my TJ before I go test out my rig on any trails, so that takes care of that concern.

Second that bar will bend/torque from regular usage. Ideally you would add two bends to the bar to strengthen the bar. I agree with this but I don’t have the room to add the bends for where I’m mounting the bar nor do I have the equipment to bend a bar of this thickness either. Additionally I do have a bushing between the crossmember and the mount that is between the adapter and the transfer case which will flex and give out before the crossmember bends.

Overall I would say about 85% of my welds did great, but that still left 15% that needed to be addressed so I’m very appreciative to everyone that added constructive feedback about the welds on my transmission/transfer case crossmember.

Here is the video if you want to watch it:

Let me know what you think.

Thanks

Grant

After getting a bunch of, mostly, constructive feedback on my welding on my crossmember for my diesel swap TJ Wrangler project in my previous post, I decided to pull the crossmember to fix all my welds. Lesson learned, don’t rush welding. I’m so far behind on this project, in terms of my own timeline, that I rushed both the welding and cleanup of the crossmember.

I also want to address a few of the concerns that were raised in my last post as well.

The first was that the crossmember would bend the first time I dropped onto an obstacle while wheeling. I’m going to be adding skid plates to my TJ before I go test out my rig on any trails, so that takes care of that concern.

Second that bar will bend/torque from regular usage. Ideally you would add two bends to the bar to strengthen the bar. I agree with this but I don’t have the room to add the bends for where I’m mounting the bar nor do I have the equipment to bend a bar of this thickness either. Additionally I do have a bushing between the crossmember and the mount that is between the adapter and the transfer case which will flex and give out before the crossmember bends.

Overall I would say about 85% of my welds did great, but that still left 15% that needed to be addressed so I’m very appreciative to everyone that added constructive feedback about the welds on my transmission/transfer case crossmember.

Here is the video if you want to watch it:

Let me know what you think.

Thanks

Grant