I edited my post to add that I’m running Centramatics. I’d noticed the vibration was reduced but not gone right after a tire rotation & balance but would come back.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please help me solve the oscillating vibration crisis by providing some basic info on your Jeep

- Thread starter freedom_in_4low

- Start date

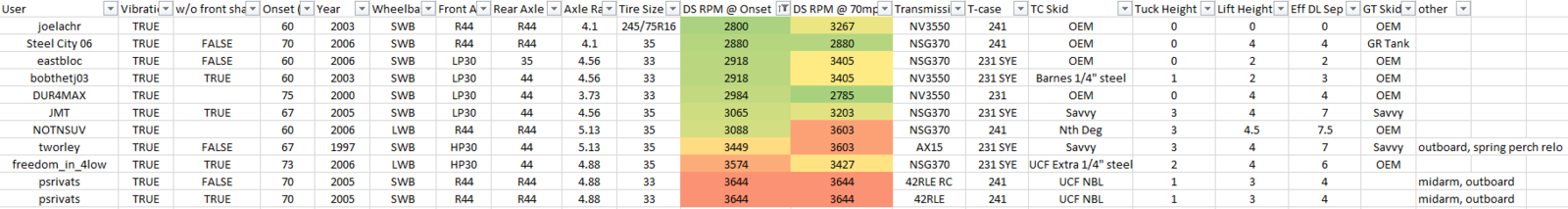

1. Yes - about 70-75 mph.There's so many threads with scattered info it's impossible to tabulate anything, so I'm asking directly for answers to the following questions - please respond EVEN IF YOU DON'T have the oscillating vibration issue. The more data the better, and I can put this in Excel and pivot table the $#!+ out of this.

1. Do you have the oscillating vibration issue and at what speed does it start?

2. does it persist even with the front driveshaft removed?

3. Model year and TJ or LJ

4. Axles and Gear ratio (and if you have a Rubicon, did you keep thick cut gears or did you get a 3.92+ carrier and go to standard gears?)

5. Tire size

6. transmission

7. transfer case, and if 231, is it SYE'd

8. stock or aftermarket transfer case skid, and if aftermarket, which skid (please include brand, tuck height, and material)

9. stock or aftermarket gas tank skid, and if aftermarket, which skid?

10. suspension lift height, if any

11. any other mods that might change the way the frame is constrained, such as a stretch, midarm, rear frame raise, crossmember deletions, spring perch relocations, shock outboard, etc.

2. No. Rear driveshaft removal also eliminates the noise.

3. 2006 TJ Rubicon

4. Stock 4.10 gears

5. 35s

6. NSG370

7. NP241. Slight play in front output yoke.

8. Stock

9. Aftermarket 24 gallon Genright gas tank with steel skid

10. 4" suspension lift

11. Body lift

My vibrations are most likely torsional vibrations rather than a balance issue. I believe the cause has to do with the front and rear driveshafts, particularly the double cardan intermediate joint, accelerating and decelerating twice per revolution. When the two double cardan intermediate joints are opposed, the vibrations are quite noticeable. As the rear tires slip relative to the front, they oscillate between being noticeable and not noticeable.

My vibrations can be "paused" by simply putting the jeep in 4WD. If I shift, say at 75 mph, at the lowest vibration point of the oscillation, it stays that way. If I shift at the highest point, the vibrations are full volume with no oscillation. Essentially, shifting into 4WD forces the shafts to move at the same speed.

The reason the vibrations oscillate is because of alternating constructive and destructive interference. The rear driveshaft almost always spins slightly faster than the front under load. It is the same effect you hear when two trumpets play the same note, but one is slightly out of tune.

The source of these vibrations is likely to do with the double cardan joint. The joint forces both ends of the driveshaft to spin at the same speed, but the intermediate yoke itself is still forced to accelerate and decelerate twice per revolution. This angular impulse has to come from somewhere, and is driven through the driveshafts to the ground, and ultimately back in through the transfer case.

One solution for this would be to ditch the double cardan for a true CV joint like a rzeppa joint or similar. However, I'm not aware of any good true CV driveshaft joints compatible with the driveshaft speeds and angles we like to run.

Another solution might be to run double-double cardan joint driveshafts. With a double cardan at each end, clocked 90 degrees apart, the rotational impulse provided by one intermediate yoke would be canceled out by the other, provided the two DC joints are run at nearly the same angle.

My vibrations are most likely torsional vibrations rather than a balance issue. I believe the cause has to do with the front and rear driveshafts, particularly the double cardan intermediate joint, accelerating and decelerating twice per revolution. When the two double cardan intermediate joints are opposed, the vibrations are quite noticeable. As the rear tires slip relative to the front, they oscillate between being noticeable and not noticeable.

My vibrations can be "paused" by simply putting the jeep in 4WD. If I shift, say at 75 mph, at the lowest vibration point of the oscillation, it stays that way. If I shift at the highest point, the vibrations are full volume with no oscillation. Essentially, shifting into 4WD forces the shafts to move at the same speed.

The reason the vibrations oscillate is because of alternating constructive and destructive interference. The rear driveshaft almost always spins slightly faster than the front under load. It is the same effect you hear when two trumpets play the same note, but one is slightly out of tune.

The source of these vibrations is likely to do with the double cardan joint. The joint forces both ends of the driveshaft to spin at the same speed, but the intermediate yoke itself is still forced to accelerate and decelerate twice per revolution. This angular impulse has to come from somewhere, and is driven through the driveshafts to the ground, and ultimately back in through the transfer case.

One solution for this would be to ditch the double cardan for a true CV joint like a rzeppa joint or similar. However, I'm not aware of any good true CV driveshaft joints compatible with the driveshaft speeds and angles we like to run.

Another solution might be to run double-double cardan joint driveshafts. With a double cardan at each end, clocked 90 degrees apart, the rotational impulse provided by one intermediate yoke would be canceled out by the other, provided the two DC joints are run at nearly the same angle.

Mine behaves the same, and my understanding of the phenomenon mostly aligns with yours, for most people (specifically, the ones whose vibrations go away with a shaft removed). But for those of us who still have it even with a shaft removed, the only remaining explanation is that there is another component with a resonance that is within reach of the driveshaft rpm. I think the vibrations from the CV's themselves would not be perceptible, but they are being transmitted through either the transmission mount or the control arms and vibrating something else somewhere in the frame or chassis. I don't know why they're being transmitted more effectively in some rigs than others, or what component(s) are resonating, or what makes that/those component(s) more likely to resonate in one rig than another.

I can also pause mine in whatever point in the oscillation I want by putting it in 4WD...if I have both shafts installed. I was hesitant to try putting it in 4WD with the front shaft out at speed since the teeth in the transfer case would be meeting at a very high differential. One of these days I might pull it again and just drive up to speed in 4WD and see what it does. I actually haven't tried that since I replaced my skid, so I may have solved my rear-only oscillation and may be ready for hubs.

That is a strong statement, which begs me to question how much time have you invested into this issue.

How many times have you moved both pinions + and - 4 degree in 0.25 increments just to realize that only thing that changes is frequency of the vibration? How about changing the lift from 2" to 4 " in 1" increments, and redoing + - 4 degree pinion angles at each lift? When you changing pinion angles, what do you think that simulates?

Maybe I'm on the wrong page as to what "this issue" is. I read this post before I saw the "vibes after regear" thread. I've had oscillating vibes on a couple jeeps, so that's how I read the question. No I haven't changed lift heights to chase vibes, I've just had vibes after lift. Changing pinion angles fixed it, and for me changing pinion angles didn't change frequency, just amplitude.

As a matter of shaft vibe fundamentals how offset the ends are is important. Especially if you include non-CV joint setups.

1. Yes @ 75mph

2. Never tested

3. 2000 TJ

4. Dana 30/44 - 3.73

5. 33/12.5/17

6. NV3550 5 speed

7. 231

8. Stock

9. Stock

10. 4"

11. N/A

2. Never tested

3. 2000 TJ

4. Dana 30/44 - 3.73

5. 33/12.5/17

6. NV3550 5 speed

7. 231

8. Stock

9. Stock

10. 4"

11. N/A

I have noticed more cars coming with true CV joints (not a double cardan) from the factory. From what I recall, either the JK or JL had a Rzeppa joint in the front driveshaft in some cases.

I recently bought a 2021 F150, which comes with the 7850 lbs GVWR and 13,800 lbs trailering package, and was surprised to see something that looks like a Rzeppa joint on the (fully aluminum) driveshaft.

CV technology is developing. Hopefully someone can bring a quality true CV driveshaft to the aftermarket. Unfortunately, the double cardan really isn’t an ideal solution, rather just a compromise that works most of the time.

It looks like Dana Spicer builds rzeppa, plunging cross groove, and double offset joints, all of which are true CV. (They of course also make the double cardan, which is not a true CV.)

The Dana Rzeppa joints look like they are rated to around 4,400 ft lbs, and a 10 degree continuous/12 degree maximum operating angle. I’ve seen a few ones that claim higher angles.

I recently bought a 2021 F150, which comes with the 7850 lbs GVWR and 13,800 lbs trailering package, and was surprised to see something that looks like a Rzeppa joint on the (fully aluminum) driveshaft.

CV technology is developing. Hopefully someone can bring a quality true CV driveshaft to the aftermarket. Unfortunately, the double cardan really isn’t an ideal solution, rather just a compromise that works most of the time.

It looks like Dana Spicer builds rzeppa, plunging cross groove, and double offset joints, all of which are true CV. (They of course also make the double cardan, which is not a true CV.)

The Dana Rzeppa joints look like they are rated to around 4,400 ft lbs, and a 10 degree continuous/12 degree maximum operating angle. I’ve seen a few ones that claim higher angles.

Last edited:

Interestingly, Dana also offers a flexible coupling for their driveshaft components that is rated to a 1 degree continuous and 2 degree maximum operating angle. They’re also designed to absorb torsional vibration. I wonder if this could be used to replace or supplement the lower single u-joint on a standard double cardan shaft…

Maybe a question to pose to Shawn Woods?Interestingly, Dana also offers a flexible coupling for their driveshaft components that is rated to a 1 degree continuous and 2 degree maximum operating angle. They’re also designed to absorb torsional vibration. I wonder if this could be used to replace or supplement the lower single u-joint on a standard double cardan shaft…

My vibrations are most likely torsional vibrations rather than a balance issue. I believe the cause has to do with the front and rear driveshafts, particularly the double cardan intermediate joint, accelerating and decelerating twice per revolution. When the two double cardan intermediate joints are opposed, the vibrations are quite noticeable. As the rear tires slip relative to the front, they oscillate between being noticeable and not noticeable.

this keeps processing in my head as I work.

Have you ever tried putting tire pressures at opposite extremes, like 15 in front and 35 in the rear, and take it for a (short) drive to see if the oscillation changed or disappeared? Better yet, if you have a spare set of wheels and smaller tires laying around, go for a drive with 31s on one axle and 35's on another.

I have not. But there are ways to change the relative forward slip of a tire. If you are coasting in 2WD the slip will be rather minimal as the loads on the front and rear tires are close to the same. If you are heavy on the throttle in 2WD, the rear tires would slip (and therefore spin) faster than the front, and if you have oscillating vibrations, you will notice the oscillations get faster.this keeps processing in my head as I work.

Have you ever tried putting tire pressures at opposite extremes, like 15 in front and 35 in the rear, and take it for a (short) drive to see if the oscillation changed or disappeared? Better yet, if you have a spare set of wheels and smaller tires laying around, go for a drive with 31s on one axle and 35's on another.

Going around a turn in 2WD your front tires will begin to spin faster than they were before. In a gentle turn with modest throttle, your front wheels will approach the speed of the rear, and the oscillations will slow down. As the turn radius decreases, the front wheels spin faster. There is a certain point at which the front wheel speeds will match the rear, and there will be no oscillation in vibration. Continue decreasing the turn radius, and the fronts will spin faster than the rear, and the vibrations will begin to oscillate in intensity again, with increasing speed of oscillation as the turn radius grows smaller.

These effects are part of the reason oscillation speed of the vibrations varies throughout a typical freeway drive, especially moreso on one with many hills and curves than a flat and straight one.

Shifting into 4Hi forces the driveshafts to travel the same speed, hence why it always pauses the vibrations. Even going around a modest turn, the driveshafts can’t spin at different rates.

Back to the musical analogy, the farther the trumpets are out of tune from one another, the faster the beat gets. The greater the speed difference in the driveshafts, the faster the beat (intensity oscillation) gets. At a certain point, our brains will interpret either case as dissonance rather than a beat. (Keep going far enough and you will approach a harmonic. That doesn’t usually happen in the case of two driveshafts - they have to spin at wildly different speeds.)

The “oscillation” that we refer to is called a “beat” in musical terms, sometimes also known as a monaural beat (to distinguish it from a binaural beat - which is a brain processing phenomenon). It is merely an alternating succession of two sources going in phase and out of phase. It happens in almost any phenomenon described by wave theories. Ocean waves, sound, mechanical vibrations, alternating current, light, and even gravity waves can all exhibit similar effects, though the way we interpret them might be different.

1. Do you have the oscillating vibration issue and at what speed does it start? - yes, 60 oscilations mostly on acceleration

2. does it persist even with the front driveshaft removed? - yes manual ft hubs

3. Model year and TJ or LJ - 2006 Tj

4. Axles and Gear ratio (and if you have a Rubicon, did you keep thick cut gears or did you get a 3.92+ carrier and go to standard gears?) - 5.13 Yukon thick it think

5. Tire size - 33x12.5 toyo mt

6. transmission - 42lre

7. transfer case, and if 231, is it SYE'd - NP241OR

8. stock or aftermarket transfer case skid, and if aftermarket, which skid (please include brand, tuck height, and material) - stock, new bracket.

9. stock or aftermarket gas tank skid, and if aftermarket, which skid? - stock

10. suspension lift height, if any - 4"

11. any other mods that might change the way the frame is constrained, such as a stretch, midarm, rear frame raise, crossmember deletions, spring perch relocations, shock outboard, etc.? All savvy dbl adjustable control arms, new chrome Molly axles, new adams drive shafts installed and balanced by adams, warn front manual locking hubs, front cam bolts replaced with solid brackets, new shocks with extension brackets (vib same before and after).

numerious small rear angle adjustments, last setting about .7* below, also I just had all 4 tires precision (?) rebalanced and rotated this got rid of most of the vibration that I could feel in my feet but I still have a little oscillation under mild acceleration I can hear in the cab from around 60 to 75 mph with the windows up.

2. does it persist even with the front driveshaft removed? - yes manual ft hubs

3. Model year and TJ or LJ - 2006 Tj

4. Axles and Gear ratio (and if you have a Rubicon, did you keep thick cut gears or did you get a 3.92+ carrier and go to standard gears?) - 5.13 Yukon thick it think

5. Tire size - 33x12.5 toyo mt

6. transmission - 42lre

7. transfer case, and if 231, is it SYE'd - NP241OR

8. stock or aftermarket transfer case skid, and if aftermarket, which skid (please include brand, tuck height, and material) - stock, new bracket.

9. stock or aftermarket gas tank skid, and if aftermarket, which skid? - stock

10. suspension lift height, if any - 4"

11. any other mods that might change the way the frame is constrained, such as a stretch, midarm, rear frame raise, crossmember deletions, spring perch relocations, shock outboard, etc.? All savvy dbl adjustable control arms, new chrome Molly axles, new adams drive shafts installed and balanced by adams, warn front manual locking hubs, front cam bolts replaced with solid brackets, new shocks with extension brackets (vib same before and after).

numerious small rear angle adjustments, last setting about .7* below, also I just had all 4 tires precision (?) rebalanced and rotated this got rid of most of the vibration that I could feel in my feet but I still have a little oscillation under mild acceleration I can hear in the cab from around 60 to 75 mph with the windows up.

Last edited:

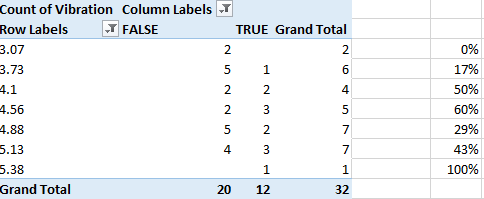

Some more interesting info as the data comes in.

Those with vibrations fall into a couple of distinct groups with respect to speed of onset.

One group starts at driveshaft speeds around 2900rpm, the other around 3500rpm (there has been a correction and a late addition at 2700 and 3300, respectively).

Effective driveline separation vs stock (how I'm referring to lift+tuck) is all over the map. We have literally every gear ratio available in a TJ either factory or aftermarket, except for the oddball 3.55. By transfer case or transfer case skid it varies some but not statistically significant for the sample size. (42% for 241, 33% for SYE'd 231). Rate of occurrence by transmission is equal enough. FWIW, the NV3550 and NSG370 reportedly weigh 90-100 pounds, numbers for the 42RLE are fuzzier but I'm come across everything from 125 to 197.

There's an interesting spike around 4.1 and 4.56. I don't know what to make of this. There's nothing unique about those ratios other than the ratio itself. Again...sample size. 4.88 does have something unique in that when applied to a 30/44 and the 44 uses standard (not thick cut) gears, the ratios don't perfectly match...but at speed it would be a difference of 0.2Hz, so at most it should be a nearly imperceptible change in the oscillation frequency. There's nothing to read into the 5.38 row, it's only one entry and he had it with 4.88, but I didn't want to double count the same rig since he's already listed in the 4.88 data as well.

Those with vibrations fall into a couple of distinct groups with respect to speed of onset.

One group starts at driveshaft speeds around 2900rpm, the other around 3500rpm (there has been a correction and a late addition at 2700 and 3300, respectively).

Effective driveline separation vs stock (how I'm referring to lift+tuck) is all over the map. We have literally every gear ratio available in a TJ either factory or aftermarket, except for the oddball 3.55. By transfer case or transfer case skid it varies some but not statistically significant for the sample size. (42% for 241, 33% for SYE'd 231). Rate of occurrence by transmission is equal enough. FWIW, the NV3550 and NSG370 reportedly weigh 90-100 pounds, numbers for the 42RLE are fuzzier but I'm come across everything from 125 to 197.

There's an interesting spike around 4.1 and 4.56. I don't know what to make of this. There's nothing unique about those ratios other than the ratio itself. Again...sample size. 4.88 does have something unique in that when applied to a 30/44 and the 44 uses standard (not thick cut) gears, the ratios don't perfectly match...but at speed it would be a difference of 0.2Hz, so at most it should be a nearly imperceptible change in the oscillation frequency. There's nothing to read into the 5.38 row, it's only one entry and he had it with 4.88, but I didn't want to double count the same rig since he's already listed in the 4.88 data as well.

Last edited:

One small correction on mine. My current tires are 265/75R16. I did have the same problem with the previous 245s but I don't remember what the onset speed was. I'm off work Monday and I'll try to get a more accurate onset speed and a front shaft out result.Some more interesting info as the data comes in.

Those with vibrations fall into a couple of distinct groups with respect to speed of onset.

One group starts at driveshaft speeds around 2900rpm, the other around 3500rpm.

View attachment 310482

Effective driveline separation vs stock (how I'm referring to lift+tuck) is all over the map. We have literally every gear ratio available in a TJ either factory or aftermarket, except for the oddball 3.55. By transfer case or transfer case skid it varies some but not statistically significant for the sample size. (42% for 241, 33% for SYE'd 231). Rate of occurrence by transmission is equal enough. FWIW, the NV3550 and NSG370 reportedly weigh 90-100 pounds, numbers for the 42RLE are fuzzier but I'm come across everything from 125 to 197.

There's an interesting spike around 4.1 and 4.56. I don't know what to make of this. There's nothing unique about those ratios other than the ratio itself. Again...sample size. 4.88 does have something unique in that when applied to a 30/44 and the 44 uses standard (not thick cut) gears, the ratios don't perfectly match...but at speed it would be a difference of 0.2Hz, so at most it should be a nearly imperceptible change in the oscillation frequency. There's nothing to read into the 5.38 row, it's only one entry and he had it with 4.88, but I didn't want to double count the same rig since he's already listed in the 4.88 data as well.

View attachment 310495

I have not. But there are ways to change the relative forward slip of a tire. If you are coasting in 2WD the slip will be rather minimal as the loads on the front and rear tires are close to the same. If you are heavy on the throttle in 2WD, the rear tires would slip (and therefore spin) faster than the front, and if you have oscillating vibrations, you will notice the oscillations get faster.

Going around a turn in 2WD your front tires will begin to spin faster than they were before. In a gentle turn with modest throttle, your front wheels will approach the speed of the rear, and the oscillations will slow down. As the turn radius decreases, the front wheels spin faster. There is a certain point at which the front wheel speeds will match the rear, and there will be no oscillation in vibration. Continue decreasing the turn radius, and the fronts will spin faster than the rear, and the vibrations will begin to oscillate in intensity again, with increasing speed of oscillation as the turn radius grows smaller.

These effects are part of the reason oscillation speed of the vibrations varies throughout a typical freeway drive, especially moreso on one with many hills and curves than a flat and straight one.

Shifting into 4Hi forces the driveshafts to travel the same speed, hence why it always pauses the vibrations. Even going around a modest turn, the driveshafts can’t spin at different rates.

Back to the musical analogy, the farther the trumpets are out of tune from one another, the faster the beat gets. The greater the speed difference in the driveshafts, the faster the beat (intensity oscillation) gets. At a certain point, our brains will interpret either case as dissonance rather than a beat. (Keep going far enough and you will approach a harmonic. That doesn’t usually happen in the case of two driveshafts - they have to spin at wildly different speeds.)

The “oscillation” that we refer to is called a “beat” in musical terms, sometimes also known as a monaural beat (to distinguish it from a binaural beat - which is a brain processing phenomenon). It is merely an alternating succession of two sources going in phase and out of phase. It happens in almost any phenomenon described by wave theories. Ocean waves, sound, mechanical vibrations, alternating current, light, and even gravity waves can all exhibit similar effects, though the way we interpret them might be different.

yep, we're on the same page 100% with that being the physical principle behind this...I've been using that principle to tune my guitar since 1998, though I don't think I actually understood it until I took physics in 2000-2001. I put some visuals to it about a year and a half ago, before I even had a rig that suffered from this.

https://wranglertjforum.com/threads...tions-after-re-gear-thread.32445/#post-691117

I just think some of us may be hearing the interference between two driveshafts, others may be hearing it between a driveshaft plus the resonant frequency of something else, or the resonant frequency of two components that are near the speed of the driveshaft, which itself isn't enough to perceive but may be enough to excite something else.

Last edited:

One small correction on mine. My current tires are 265/75R16. I did have the same problem with the previous 245s but I don't remember what the onset speed was. I'm off work Monday and I'll try to get a more accurate onset speed and a front shaft out result.

got it. Your onset speed is way low compared to everyone else (2700rpm @60mph). I don't know what that tells us, if anything, but it's interesting.

they don't list this skid on their website, do you know about how much it lifts the transfer case?

nice skid...looks like a marriage between a UCF Ultra and the separate crossmember design of Savvy. Thanks!