You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your TJ today?

- Thread starter LJRubiconGuy

- Start date

You are not alone in being sceptical that you did everything right! I danced around doing mine with fear of the unknown for over a month until I was forced to do it, but lets be honest in the end it is easier than changing out the spark plugs, you cant go wrong if the bolts come out and you "establish TDC"Yesterday I replaced my 05's OEM OPDA (it had an '04 date code inside its housing) with a new Crown unit. I have not had the barrel of monkeys noise that I could recall, so this was preventative maintenance.

I followed the usual steps found in all the tutorials and write-ups, used the original cam sensor, got everything back together, and (holding my breath) the Jeep started up and ran until normal operating temperature with no codes. I didn't have a chance to test drive it last night. I should be able to do this today. I will say, I don't think I have any valve/lifter tick now. It was always minimal anyway, but my ears couldn't hear any.

As with other projects where I encounter minimal hiccups, I'm skeptical I did everything right. I read horror stories and I didn't (so far) have that type of experience. (The worst of the project was cutting a slot into one of the old OPDA's cover screws because the T25 rounded out due to the angle of getting a tool in there.) I can't be the only one who doubts themselves after doing this stuff, can I?

I found the similar type of wear on my old OPDA everyone else reports; but the cam did not look similarly worn.

View attachment 244801

My 06 had slightly less wear on the gear but my oil pump drive key end showed wear

Piece of mind and just one more thing to forget about and advise others on.

But why are these cable shifters so damn expensive?! That’s why I haven’t done it yet to be honest as much as I want to. Just seems way overpriced to me. Still holding out for a junkyard find for nowThis mod is coming up to the top of my list fairly quickly now...

5632

Love me some Target!!!

The longer the wait the higher the price.But why are these cable shifters so damn expensive?! That’s why I haven’t done it yet to be honest as much as I want to. Just seems way overpriced to me. Still holding out for a junkyard find for now

I got an AA unit last Summer and time flew without installing it. Now that I am getting ready to swap out the skid plate and front drive shaft I will also install it.The longer the wait the higher the price.

Agreed. That's why mine hasn't been done as yet either. I don't see any expense in making the product!But why are these cable shifters so damn expensive?! That’s why I haven’t done it yet to be honest as much as I want to. Just seems way overpriced to me. Still holding out for a junkyard find for now

Is it hard to adjust? I'm debating if I should do it now or wait until I install my body lift (if I decide to install it) but I'm unsure how annoying adjusting twice would beI installed the savvy cable shifter kit on my transfer case today. What an improvement over the stock linkage.

You would not have to adjust it twice - once you get it set, adding a body lift would make no difference. In fact, the body lift will be a bit easier with the cable shifter already installed.Is it hard to adjust? I'm debating if I should do it now or wait until I install my body lift (if I decide to install it) but I'm unsure how annoying adjusting twice would be

Thanks for that, glad I'm not the only one.You are not alone in being sceptical that you did everything right! I danced around doing mine with fear of the unknown for over a month until I was forced to do it, but lets be honest in the end it is easier than changing out the spark plugs, you cant go wrong if the bolts come out and you "establish TDC"

My 06 had slightly less wear on the gear but my oil pump drive key end showed wear

Piece of mind and just one more thing to forget about and advise others on.

Great, I might as well install it now while I have my skid plate offYou would not have to adjust it twice - once you get it set, adding a body lift would make no difference. In fact, the body lift will be a bit easier with the cable shifter already installed.

Speaking of, yesterday I was able to get my transfer case skid plate off. The bolts that were put on with the transfer case drop (which I am removing) were terrible internal hex bolts and all got rounded badly.

I was able to cut the bolts through the bracket (since its getting thrown out anyway) and then grind down the nutserts and bolts to pound the old ones through the frame with a socket and hammer.

Unfortunately I had to rent a 7" angle grinder from home depot because my 4 1/2" one wouldn't fully reach the bolts, but I made it work. I tried with my sawzall but it wasn't really cutting the bolt and my blade got destroyed fast.

Now I have to wirewheel all the rust off of the frame/skidplate and then paint them, install the new black magic nutserts and bolts, install the savvy shifter cable and do a transfer case fluid change and it should be good to go. Also pulled my front driveshaft while it was off to see if that will get rid of my slight vibrations

I was able to cut the bolts through the bracket (since its getting thrown out anyway) and then grind down the nutserts and bolts to pound the old ones through the frame with a socket and hammer.

Unfortunately I had to rent a 7" angle grinder from home depot because my 4 1/2" one wouldn't fully reach the bolts, but I made it work. I tried with my sawzall but it wasn't really cutting the bolt and my blade got destroyed fast.

Now I have to wirewheel all the rust off of the frame/skidplate and then paint them, install the new black magic nutserts and bolts, install the savvy shifter cable and do a transfer case fluid change and it should be good to go. Also pulled my front driveshaft while it was off to see if that will get rid of my slight vibrations

brett313

Member

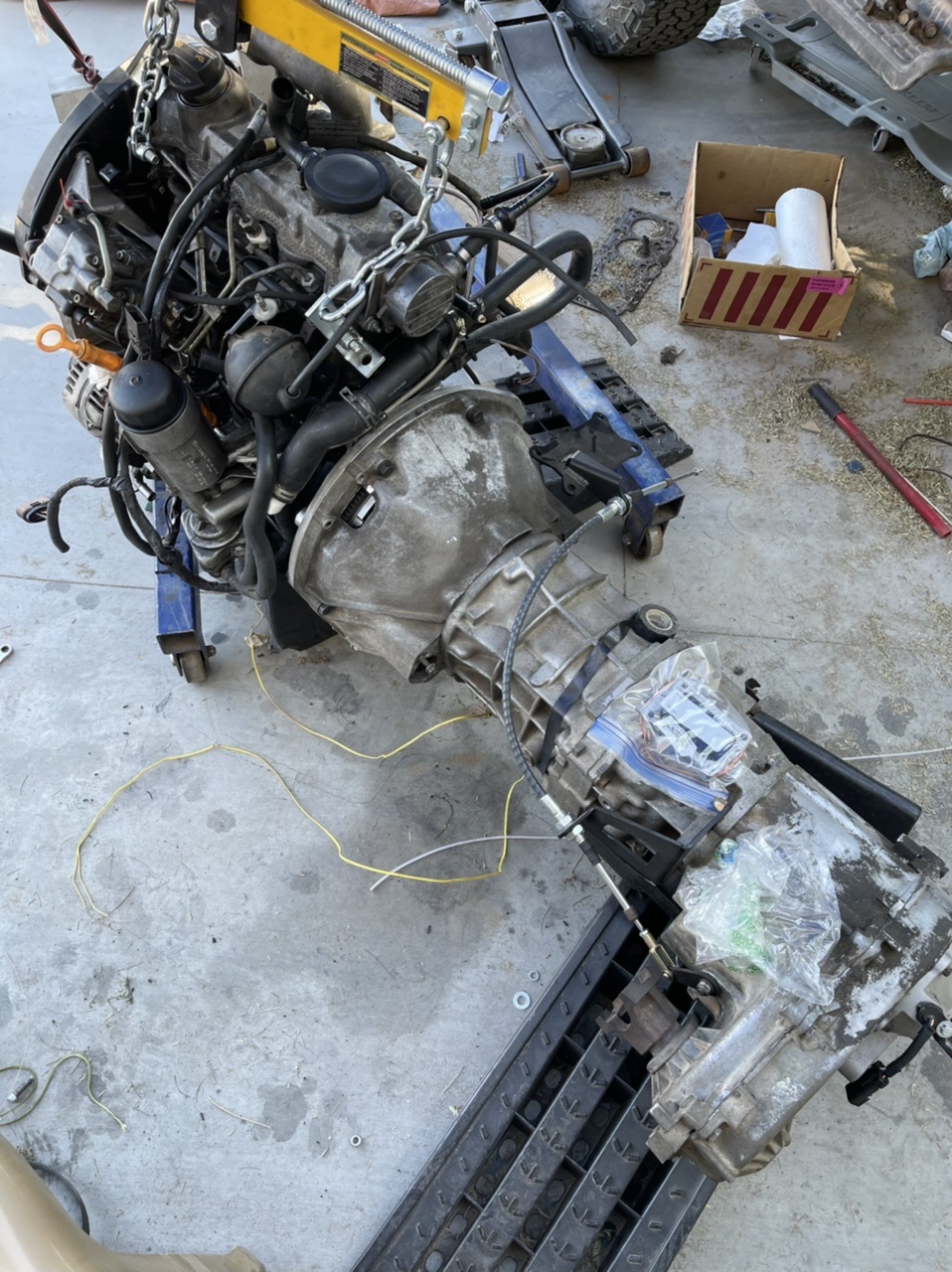

Just dropping in a quick drivetrain upgrade today

You would only have to adjust it onceIs it hard to adjust? I'm debating if I should do it now or wait until I install my body lift (if I decide to install it) but I'm unsure how annoying adjusting twice would be

5632

Love me some Target!!!

brett313

Member

I like those. Which ones are they?Here are a few pictures of the rock rails me and @AndyG installed. Before & after for comparison. Should have taken the plastic piece off before install and will do that later.

View attachment 243921

View attachment 243922

View attachment 243923

View attachment 243924

View attachment 243925

View attachment 243926

And......?Took the TJ and the wife for a little road trip, we had been wanting to try out a little restaurant in Guntersville, so it was road trip Sunday!!!!

View attachment 244861

We didn't leave hungryAnd......?

That’s either a copy/paste from somewhere or you just impressed the $h!t out of me! Number 4 is 100% accurate!

- If you change the way you look at things, the things you look at change.

- You must be the change you wish to see in the world.

- When we are no longer able to change a situation - we are challenged to change ourselves.

- Change will not come if we wait for some other person or some other time. We are the ones we've been waiting for. We are the change that we seek.

RFAASRMA

TJ Enthusiast

It wasn’t too bad to adjust. I think I lucked out to be honest. I had the shifter all the way down to 2-high and made sure the t-case was in the same position. The adjustments mainly came when I needed to thread the connectors onto the cable ends to match up to the t-case and shifter levers. If I didn’t have enough thread that I was comfortable with I’d adjust the large bolts holding the cables in place to make up the difference. Everything seemed pretty dialed in as long as I was able to make those adjustments. I’d be interested to see if others had similar experiences with theirs.Is it hard to adjust? I'm debating if I should do it now or wait until I install my body lift (if I decide to install it) but I'm unsure how annoying adjusting twice would be

I would think installing it before the body lift makes the most sense so you don’t lose the ability to shift in the process.