You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Work Bench & Garage Version 2

- Thread starter FarFire70

- Start date

Very nice. Might want a slight upward angle in case you bump into the shelves the grinder won't fall off. Also that will transfer the weight a little more towards the bracket.

Edit: like 10°-15° should be enough

Agreed. That'd be the plan. Pics were a quick 30-sec 'would this work'. I'm thinking I'd put short bars below the grinder holders for the discs (bar would be at an angle too

I use a piece of flat stock and hang them by the wheel guard (no pic at the moment). Same sorta idea as the round bar, but doesn't require the handle (which is generally not mounted on my grinders).

Planning to repurpose this area with auto tools that are on the shelves now since this is a wasted 'catch all' right now that I throw in the extension cords but rarely grab till from...

Rehomed the auto related tools. Makes sense to me to have them here.

Creates new shelf space

Have to figure out where/how I plan to store extension cords. This will join my other pile to figure out. I'll figure out a new home for the drills too...

This stuff goes to the basement.

This workbench project has made me focus that the garage is about garage tools and the shed and basement can store the other tools...

Creates new shelf space

Have to figure out where/how I plan to store extension cords. This will join my other pile to figure out. I'll figure out a new home for the drills too...

This stuff goes to the basement.

This workbench project has made me focus that the garage is about garage tools and the shed and basement can store the other tools...

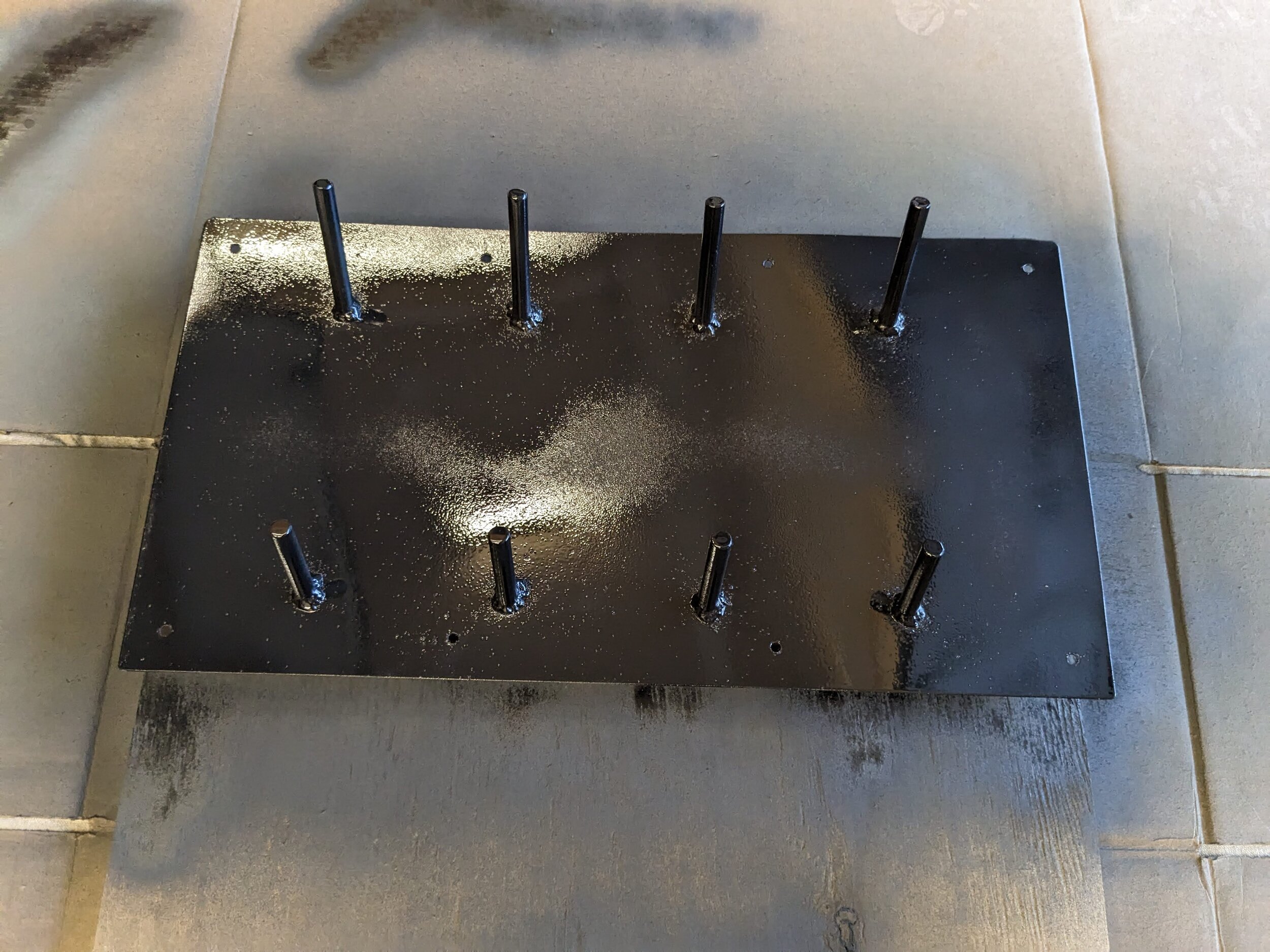

Worked on the grinder storage solution.

I'm using 14ga since I have a 24"x48" section from when I bought some for repairs on my torque boxes. I think 1/8" would be sturdier but, once I mount it against the full plywood sheet on the side of the shelving unit, I think it'll be plenty sturdy.

Used angle iron as a straight edge. I tried to use it by pushing the griding disc across it but drifted on my first cut. Started using the iron as a guide for continuous plunge cuts and had much more success.

I'll be mounting it with 1/4" bolts I have lying around.

Used my HF Belt & Disc Sander for the first time. I really like how easy it was to get consistent angle grinds and add chamfers.

Definitely not my prettiest welds, but I think they'll hold up over time. I didn't do much to clean up any of the splatter since it's just a holding tools in the garage.

Primed it with self-etching primer front and back and hit the front with flat black. I'll get the back tomorrow.

Also put together a mounting plate for my vise on the workbench.

Took about 3 hours. I could have been quicker but I took a bit to get to learn the sander and figuring out a best approach for the straight cuts.

I'm using 14ga since I have a 24"x48" section from when I bought some for repairs on my torque boxes. I think 1/8" would be sturdier but, once I mount it against the full plywood sheet on the side of the shelving unit, I think it'll be plenty sturdy.

Used angle iron as a straight edge. I tried to use it by pushing the griding disc across it but drifted on my first cut. Started using the iron as a guide for continuous plunge cuts and had much more success.

I'll be mounting it with 1/4" bolts I have lying around.

Used my HF Belt & Disc Sander for the first time. I really like how easy it was to get consistent angle grinds and add chamfers.

Definitely not my prettiest welds, but I think they'll hold up over time. I didn't do much to clean up any of the splatter since it's just a holding tools in the garage.

Primed it with self-etching primer front and back and hit the front with flat black. I'll get the back tomorrow.

Also put together a mounting plate for my vise on the workbench.

Took about 3 hours. I could have been quicker but I took a bit to get to learn the sander and figuring out a best approach for the straight cuts.

I'd use this experience to convince the wife that I need a plasma cutter. But I barely got 'approval' to spend these few hours in the garage on Mother's Day weekend.

So I won't push my luck, so I stay on this Earth...

So I won't push my luck, so I stay on this Earth...

I'd use this experience to convince the wife that I need a plasma cutter. But I barely got 'approval' to spend these few hours in the garage on Mother's Day weekend.

So I won't push my luck, so I stay on this Earth...

Big, enclosed cabinets can hide a lot of tool purchases.

Just sayin’…

Last edited:

Grinder holder install.

Vise mounted (finally) with the metal backing plate:

I love the grinder setup. Out of the way but easily accessible.

Vise is needed for a couple upcoming project so glad it's secured in place. Ran a double (side-by-side) 4x4 within the workbench in that area to mount the vise. 6" bolts to hold it in place.

Vise mounted (finally) with the metal backing plate:

I love the grinder setup. Out of the way but easily accessible.

Vise is needed for a couple upcoming project so glad it's secured in place. Ran a double (side-by-side) 4x4 within the workbench in that area to mount the vise. 6" bolts to hold it in place.

Eyelet lag bolts into the ceiling joints installed and made use of... There's 6 eyelets up there.

Changed over the welder to 240V for today's project (in my build thread), probably overkill for the metal thickness.

Realized the tool cart needed to move over a touch.

Floor jack fits in between the cart and paint cabinet, barely, by nudging over the cart.

Funny the little details you miss sometimes in moving things around.

Changed over the welder to 240V for today's project (in my build thread), probably overkill for the metal thickness.

Realized the tool cart needed to move over a touch.

Floor jack fits in between the cart and paint cabinet, barely, by nudging over the cart.

Funny the little details you miss sometimes in moving things around.

I wanted to clean out the screwdriver drawer.

So of course, I focus my attention on the mini-containers and all the hardware within... It's garage logic.

The mini-containers held 40+ years of hardware after inheriting 10 years ago these from my grandfather who just passed at 100 years old.

Didn't grab too many pics along the way, but here is about where we started:

Empty spots were in the house being worked. Every cell had something within.

A lot was 'you never know when you need it', and a lot of that was inherited parts that were never needed.

Working it:

Went through a bucket of OEM hardware from years of pulling parts off. Never needed those bolts/nuts.

Used rethread tool kit as my tester — I really need to buy a thread check tool for the garage...

'Final' results:

Tossed about 15-20 lbs of hardware that would never be used. And made it so much easier next time I need a bolt.

So of course, I focus my attention on the mini-containers and all the hardware within... It's garage logic.

The mini-containers held 40+ years of hardware after inheriting 10 years ago these from my grandfather who just passed at 100 years old.

Didn't grab too many pics along the way, but here is about where we started:

Empty spots were in the house being worked. Every cell had something within.

A lot was 'you never know when you need it', and a lot of that was inherited parts that were never needed.

Working it:

Went through a bucket of OEM hardware from years of pulling parts off. Never needed those bolts/nuts.

Used rethread tool kit as my tester — I really need to buy a thread check tool for the garage...

'Final' results:

Tossed about 15-20 lbs of hardware that would never be used. And made it so much easier next time I need a bolt.

Cleaned out the very small (called them jeweler's screwdrivers) and small screwdrivers.

Those little assholes would bind up and make my screwdriver harder to close any time I pulled/placed a screwdriver. It's a low-profile drawer.

So much 'cleaner':

Ah, feel good working 2 evenings on the mini-containers to then spend 5 minutes on the original task —- cleaning out the screwdriver draw.

Those little assholes would bind up and make my screwdriver harder to close any time I pulled/placed a screwdriver. It's a low-profile drawer.

So much 'cleaner':

Ah, feel good working 2 evenings on the mini-containers to then spend 5 minutes on the original task —- cleaning out the screwdriver draw.

slowly organizing all my small stuff.

Very efficient use of space

I can see needing another cabinet-type solution in my future for some items I still have in boxes on the floor since the re-organization.

Went through Grandpa's tool kit that he had up until his passing. I inherited most of his tools when he went into a nursing home with my Grandma. This was the tools he still had and used, even at 100 years old.

Pretty good kit for what would come up in a home setting!

I was about to open this one but I have a spot in my garage for cool old boxes for small parts (cool, interesting, or reminiscent graphics) so this one is going up on that shelf until it weathers/yellows so much that it warrants opening it to use the tool. [Pretty rare today — 'Made in USA' for a tool like this]

You don't see these old wrench holders often. Perfectly effective in their design and intended use.

I believe he had this leftover from his time as a Army civilian, designing artillery shells, and I believe it was for file folder storage. It has a nice hammer paint (not actual hammered) finish on it. That was his tool chest for this kit. Gotta love the Great Depression/WW2 generation and their creative re-use.

I pilfered the screwdrivers, compound square, vise grips, pliers, and string level. The rest is going to the basement as stock for my twins to build out their own tool sets, when the time comes.

Pretty good kit for what would come up in a home setting!

I was about to open this one but I have a spot in my garage for cool old boxes for small parts (cool, interesting, or reminiscent graphics) so this one is going up on that shelf until it weathers/yellows so much that it warrants opening it to use the tool. [Pretty rare today — 'Made in USA' for a tool like this]

You don't see these old wrench holders often. Perfectly effective in their design and intended use.

I believe he had this leftover from his time as a Army civilian, designing artillery shells, and I believe it was for file folder storage. It has a nice hammer paint (not actual hammered) finish on it. That was his tool chest for this kit. Gotta love the Great Depression/WW2 generation and their creative re-use.

I pilfered the screwdrivers, compound square, vise grips, pliers, and string level. The rest is going to the basement as stock for my twins to build out their own tool sets, when the time comes.

I’ll throw in my 2 cents, a bit late. Started around 14 in 1 car garage. Fast forward 40 plus years, a rented shop, then 1 1/2 car garage and now a 3 bay shop plus loft, plus the 1 1/2 car garage.

As your needs change and you need modifications, and the years pass, you appreciate what you did right years ago that allows you to continue to use that idea, vs scrapping it and rebuilding something.

I prefer keeping metal work separate from wood work. Wood chips and flying sparks just worry me. But I get you need to do both today. Separate shop is car and welding, home garage is woodworking and wife’s parking spot.

#1 : Equipment on casters or equipment dollies The good casters dollies cheap, but after 10-20 years you appreciate how well stuff moves vs crappy little casters that get stuck

The 1 1/2 car garage is wife’s parking spot. So I can request a day or two, or less, my equipment is out in the middle, job done, and back to normal in no time. Me happy, wife happy. Totally worth it to put casters on workbench for a larger woodworking project. Same goes for steel welding bench for access or if it’s better to weld outdoors.

#2 Vidmar style industrial cabinets. Yep, I know, pricey used. Buuut, what I paid 10 years ago, I’d get double today. It’s an investment. I was amazed how I could put an entire garage of all kinds of hardware into my first Vidmar. 1 for home garage use, 1 for car/welding shop use and 1 dedicated to car parts for a car u def going a frame off. Wish I had space for more! The beauty, totally configurable. Get the variety of different sized plastic bins vs steel dividers, grab the 3 bins you need and bring to project. The other beauty, you open one drawer, and everything in that category is staring at you. I just buy my hardware in bulk on commercial sites, and save tons of time making trips to store, as it’s easy to see what I’m running low on.

#3. Roll around tool cabinets for specific work. Got a few big main tool boxes that rarely move, but for auto work, I can get 90% of tools into one good roll around. I stress good roll around as 1’m amazed at how much weight I got into my MAC roll around. Yep, paid more $$ for my used Mac than HF, it’s worth double or more now. Also have roll around for my metal body work and welding. Grinders, die grinders, all the welding tools one spot always, and rolls to where I need it.

#4. Yeah it’s pricey and requires a high ceiling. A car lift. Of course depends on how much work you do. Recently my car lift was invaluable for restoring a few trailers. Painting underneath, no problem, push the button. Yeah I know it’s expensive and all that, but trust me, as you get older, you’ll just say one thing, damn, wish I could have bought this sooner. But yeah, build the detached shop first.

Make it all roll, and the shop changes to meet this weeks project. I laid out my last shop on CAD, yep, worth it. I still need more stuff on casters . It really pays off if you do a variety of changing projects.

. It really pays off if you do a variety of changing projects.

As your needs change and you need modifications, and the years pass, you appreciate what you did right years ago that allows you to continue to use that idea, vs scrapping it and rebuilding something.

I prefer keeping metal work separate from wood work. Wood chips and flying sparks just worry me. But I get you need to do both today. Separate shop is car and welding, home garage is woodworking and wife’s parking spot.

#1 : Equipment on casters or equipment dollies The good casters dollies cheap, but after 10-20 years you appreciate how well stuff moves vs crappy little casters that get stuck

The 1 1/2 car garage is wife’s parking spot. So I can request a day or two, or less, my equipment is out in the middle, job done, and back to normal in no time. Me happy, wife happy. Totally worth it to put casters on workbench for a larger woodworking project. Same goes for steel welding bench for access or if it’s better to weld outdoors.

#2 Vidmar style industrial cabinets. Yep, I know, pricey used. Buuut, what I paid 10 years ago, I’d get double today. It’s an investment. I was amazed how I could put an entire garage of all kinds of hardware into my first Vidmar. 1 for home garage use, 1 for car/welding shop use and 1 dedicated to car parts for a car u def going a frame off. Wish I had space for more! The beauty, totally configurable. Get the variety of different sized plastic bins vs steel dividers, grab the 3 bins you need and bring to project. The other beauty, you open one drawer, and everything in that category is staring at you. I just buy my hardware in bulk on commercial sites, and save tons of time making trips to store, as it’s easy to see what I’m running low on.

#3. Roll around tool cabinets for specific work. Got a few big main tool boxes that rarely move, but for auto work, I can get 90% of tools into one good roll around. I stress good roll around as 1’m amazed at how much weight I got into my MAC roll around. Yep, paid more $$ for my used Mac than HF, it’s worth double or more now. Also have roll around for my metal body work and welding. Grinders, die grinders, all the welding tools one spot always, and rolls to where I need it.

#4. Yeah it’s pricey and requires a high ceiling. A car lift. Of course depends on how much work you do. Recently my car lift was invaluable for restoring a few trailers. Painting underneath, no problem, push the button. Yeah I know it’s expensive and all that, but trust me, as you get older, you’ll just say one thing, damn, wish I could have bought this sooner. But yeah, build the detached shop first.

Make it all roll, and the shop changes to meet this weeks project. I laid out my last shop on CAD, yep, worth it. I still need more stuff on casters

I’ll throw in my 2 cents, a bit late. Started around 14 in 1 car garage. Fast forward 40 plus years, a rented shop, then 1 1/2 car garage and now a 3 bay shop plus loft, plus the 1 1/2 car garage.

Somehow missed your post and only catching it coming over to post an update.

I prefer keeping metal work separate from wood work. Wood chips and flying sparks just worry me. But I get you need to do both today. Separate shop is car and welding, home garage is woodworking and wife’s parking spot.

I get the safety angle. These days, I'm getting better at making sure my grinder sparks aren't landing on the fuel containers. Mostly because they are out in the shed now... [wishing I was being more joking than serious...

#2 Vidmar style industrial cabinets. Yep, I know, pricey used. Buuut, what I paid 10 years ago, I’d get double today. It’s an investment. I was amazed how I could put an entire garage of all kinds of hardware into my first Vidmar. 1 for home garage use, 1 for car/welding shop use and 1 dedicated to car parts for a car u def going a frame off. Wish I had space for more! The beauty, totally configurable. Get the variety of different sized plastic bins vs steel dividers, grab the 3 bins you need and bring to project. The other beauty, you open one drawer, and everything in that category is staring at you. I just buy my hardware in bulk on commercial sites, and save tons of time making trips to store, as it’s easy to see what I’m running low on.

Vidmars are amazing! Had them a a prior job and they're great. Definitely not free but you get every dollar's worth in their versatility and strength.

#4. Yeah it’s pricey and requires a high ceiling. A car lift.

I was just saying to the wife how much I really want a lift. I just need to remove the beam holding up the bedroom above the garage....

Ugh, guess it's not likely in the cards in this house.

Make it all roll, and the shop changes to meet this weeks project. I laid out my last shop on CAD, yep, worth it. I still need more stuff on casters. It really pays off if you do a variety of changing projects.

Agreed - CAD has been so helpful! Just need to keep mine updated as I go along.

I keep hearing about casters and I get it for a larger workspace. With my garage (likely closer to your 1.5 car garage than the 2-car this one says it is), There isn't much moving things around, other than what already comes with wheels.

When I put in the new workbench, the spot this shelving unit occupied was where the new tall shelving unit now lives. So everything on it came off and have lived in plastic containers, until today.

It was an 80/90's 'country home' style shelfing unit that was a family hand-me-down. It was the perfect depth and height for nail/screw boxes & spray bottles. I've used it for probably 20 years in various basements/garages for this use.

Welp, today we had a falling out...

It was an 80/90's 'country home' style shelfing unit that was a family hand-me-down. It was the perfect depth and height for nail/screw boxes & spray bottles. I've used it for probably 20 years in various basements/garages for this use.

Welp, today we had a falling out...

I'd been searching online and racking my brain for a good solution that wouldn't turn into a project all it's own.

I also don't have a table saw (I need to invest in one), so I'm limited in some of the clever solutions I saw around.

Instead, I just scrap 2x4s and a pocket hole jig.

I didn't want these on the wall with the door into the house as I worried they'd work themselves off the shelves over time with the door closing. Tested this with the garage door and they haven't moved any that I can tell.

Funnels and extension cords went up on 10d nails.

Emptied all of these!

And got my 'project shelf' emptied! I had designed this shelf to hold project parts and pieces but had been holding the bins with the nails, drill bits, etc.

Now I have it back! So much of the stuff on the workbench will move over here.

I need a new clock solution... Been good for 20 years but doesn't work in this setup.

I also don't have a table saw (I need to invest in one), so I'm limited in some of the clever solutions I saw around.

Instead, I just scrap 2x4s and a pocket hole jig.

I didn't want these on the wall with the door into the house as I worried they'd work themselves off the shelves over time with the door closing. Tested this with the garage door and they haven't moved any that I can tell.

Funnels and extension cords went up on 10d nails.

Emptied all of these!

And got my 'project shelf' emptied! I had designed this shelf to hold project parts and pieces but had been holding the bins with the nails, drill bits, etc.

Now I have it back! So much of the stuff on the workbench will move over here.

I need a new clock solution... Been good for 20 years but doesn't work in this setup.