You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help Diagnosing Engine Knock

- Thread starter The Goblin

- Start date

-

- Tags

- engine knock flex plate

I've been debating all day what to do. I'm thinking cam/lifters and send it. Don't want to go down the rabbit hole and rebuild the whole thing.I mean, for a junkyard 4.0 with unknown miles that holds good oil pressure? Meh.

Runs awesome just that cold start noise... and maybe I can contribute to this thread by pulling the lifters and cam and see if it solves the noise problem.

I just looked at the cam pics and saw what you said about good oil pressure. If it's a junkyard motor and you or what you are dealing with, screw it. Run the thing in to the ground. Cam looks beat up too but it's impossible to tell how bad from the pics. If it were me, I find another motor to put on a stand and start rebuilding, and run what you got. On the cam swap, if it's eating itself, replacing it and the lifters might solve your noise and let the motor live longer. It could also explain why the bearings look like that. It's a whole different project to swap the cam vs the direction you've torn into it so far, but your labor is free and parts aren't too expensive either. I'd do it.

Yeah, I pulled the trigger. Cam and lifters set supposed to ship directly from Melling so idk how long until it gets here.

Good luck. The new cam and lifters should tell us once and for all the source of the cold start noise. I'm almost certain it's worn lifters. But having had several 4.0s with the exact same noise, I'm also pretty certain the engine could go hundreds of thousands of miles before it caused a failure.

Update. My camshaft kit from Melling still has not shipped so I'll probably cancel my summit order and order the Melling cam and sealed power lifters from rockauto. I also debated an aftermarket cam but I've been there done that and really would like a stock cam. Also, my HP Tuners doesn't support this PCM so I can't get anything that'll need tuning anyways. Although I did read somebody was able to download beta software and get it to work. Anyways..

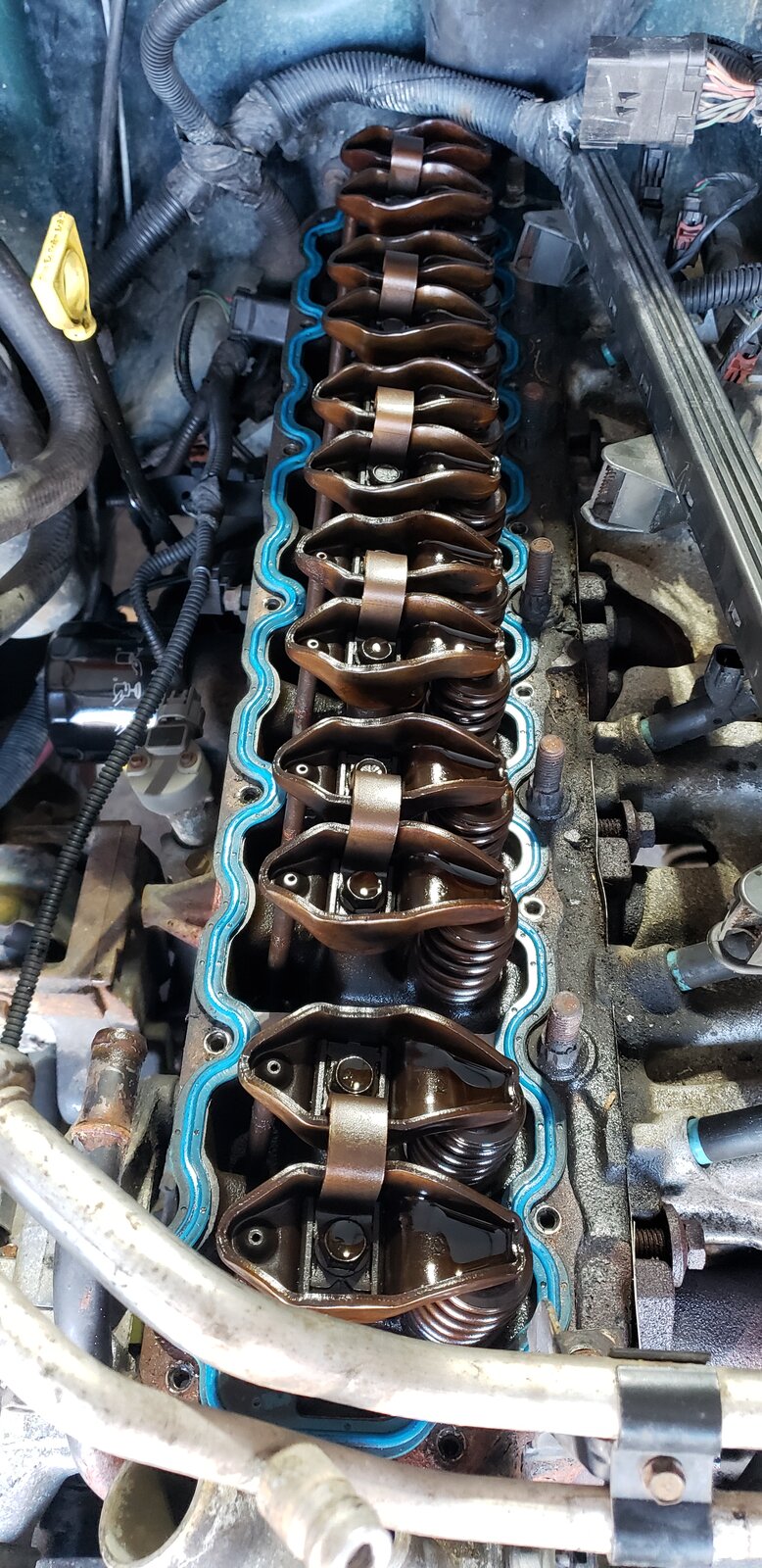

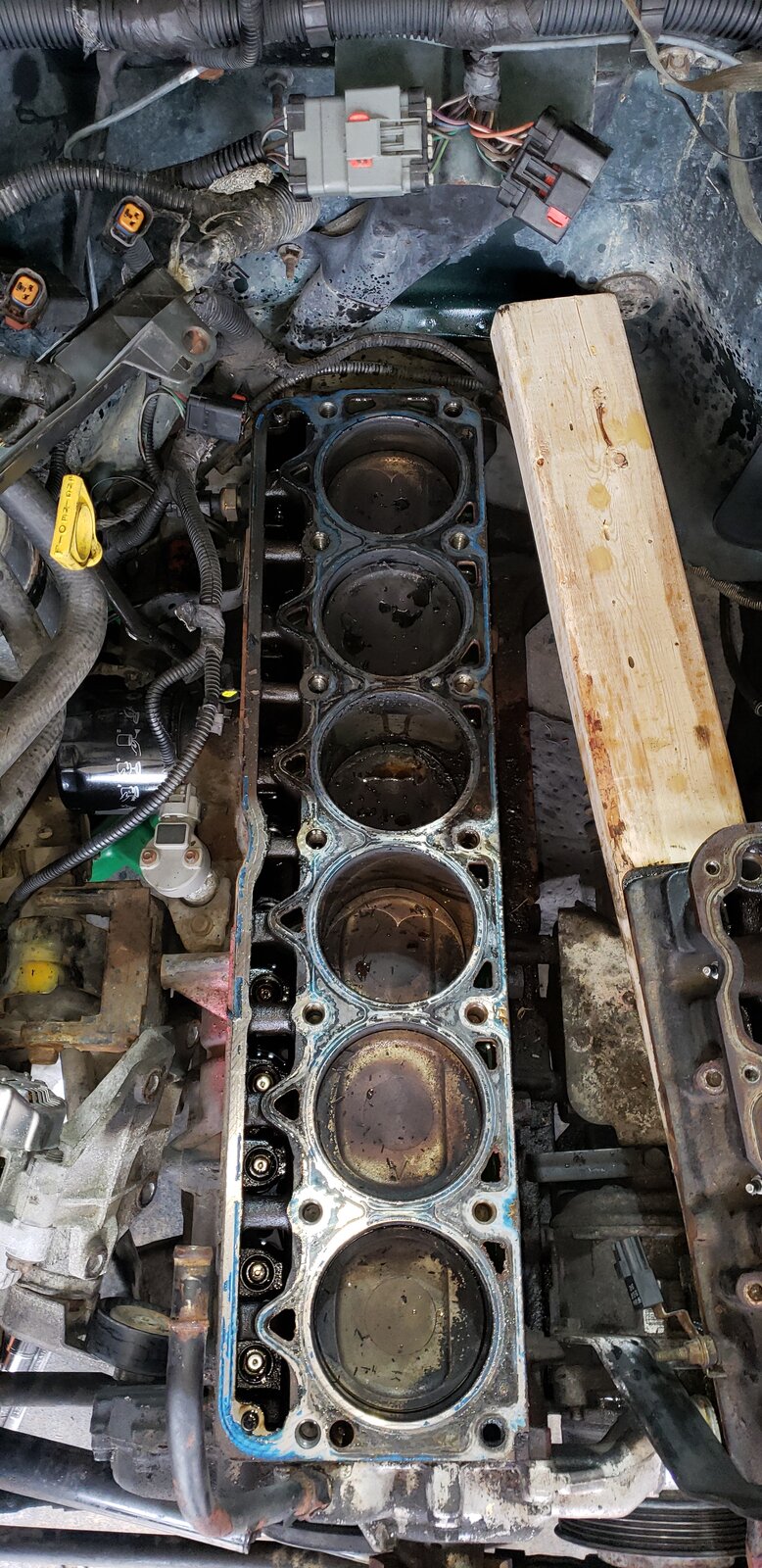

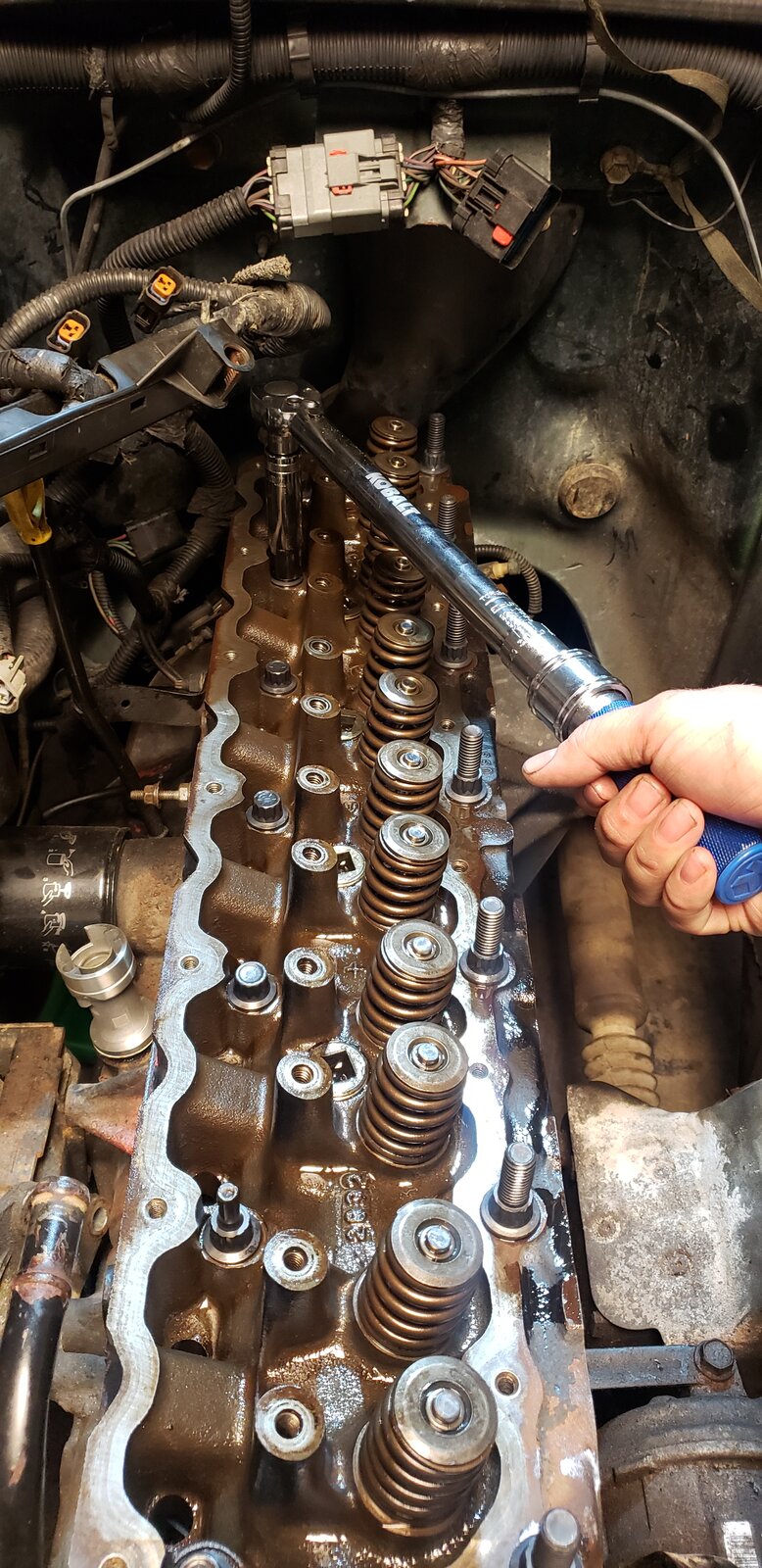

I just got the head off and the lifters pulled today. I'm fairly surprised how clean this engine is. I'm also surprised with the condition of the lifters after seeing the condition of the cam lobes.

I've attached a picture of a lifter from cylinder 4, the 7th lifter from the front of the engine. They all looks the same. They all spun nicely in their bores when i rotated the engine and came out mostly easyioy. Cylinder 6 lifters were a bit tougher but easily. When I get time I plan to disassemble each lifter and inspect them internally.

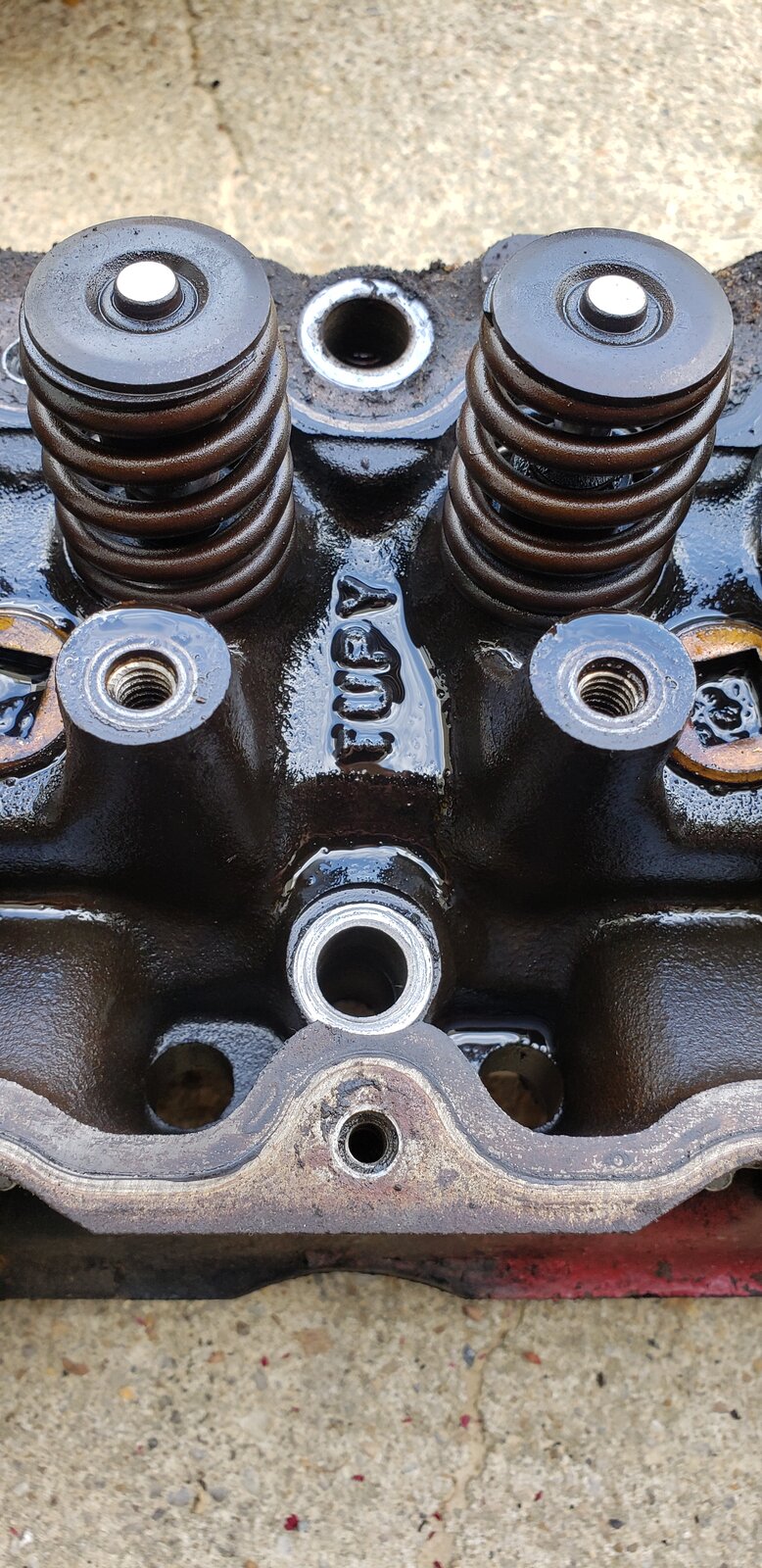

My jeep is a 2001 but the junkyard engine casting number makers me think it's a 2003 engine. It has the TUPY head so if I'm not mistaken the engine has to be older than 2001.

I just got the head off and the lifters pulled today. I'm fairly surprised how clean this engine is. I'm also surprised with the condition of the lifters after seeing the condition of the cam lobes.

I've attached a picture of a lifter from cylinder 4, the 7th lifter from the front of the engine. They all looks the same. They all spun nicely in their bores when i rotated the engine and came out mostly easyioy. Cylinder 6 lifters were a bit tougher but easily. When I get time I plan to disassemble each lifter and inspect them internally.

My jeep is a 2001 but the junkyard engine casting number makers me think it's a 2003 engine. It has the TUPY head so if I'm not mistaken the engine has to be older than 2001.

Now that I've had a few minutes to wipe the tappets off and inspect them closer I can see they're not as good as I first thought. I'm seeing pitting thag matches that of the cam lobes and I'm seeing some rings on the tappet surface of some.

That circular wear pattern is a good thing. If they aren't constantly spinning, they die quick. I don't see anything crazy wrong with those lifters, but it is super hard to tell from pics.

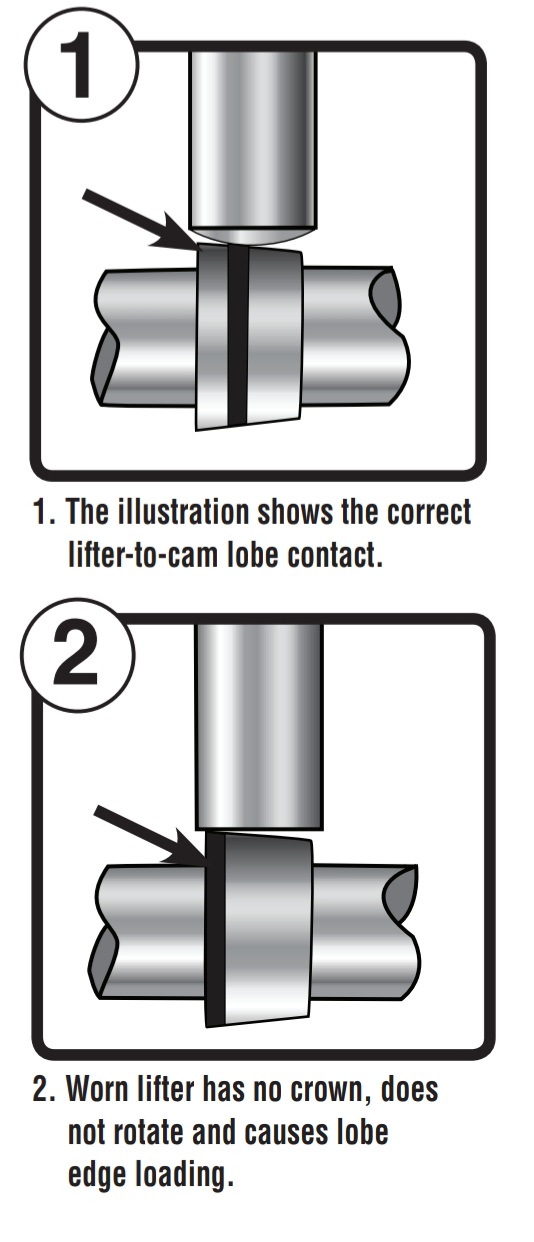

My concern is the lobe wear. Every lobe has wear on the edge. What I've read is that this is called edge loading and is due to the crown on the face of the lifter being worn down. "The lobes will first chip and gall" which is also what my lobes are doing.

Notice each lobe has a silver wear pattern on the edges.

Here is a quote from a crower cam/information pdf I'm reading

EDIT: I shared the picture with the rings because the lifter looks possibly concaved in the center. I'll inspect them more today.

"CAMSHAFT LOBE EDGE LOADING

A camshaft cannot withstand the load it receives

if the force is concentrated on the edges of the

lobes. The lobes will first chip and gall. Soon one

or more lobes will be completely wiped out. This

destruction can occur very rapidly. Wiped out

lobes, accompanied by cupped lifters, are usually

discovered due to noise or rough engine operation.

When a worn lobe is found on a camshaft, the

first reaction is to say it was “too soft”. But cast

iron camshafts are hardened as a unit, so one lobe

can’t be softer than another. If the lobes nearby

are examined, they will probably be worn on the

edges. The rest of the lobes would have eventually

failed, but one went first and tipped off the

operator that something was wrong."

Notice each lobe has a silver wear pattern on the edges.

Here is a quote from a crower cam/information pdf I'm reading

EDIT: I shared the picture with the rings because the lifter looks possibly concaved in the center. I'll inspect them more today.

"CAMSHAFT LOBE EDGE LOADING

A camshaft cannot withstand the load it receives

if the force is concentrated on the edges of the

lobes. The lobes will first chip and gall. Soon one

or more lobes will be completely wiped out. This

destruction can occur very rapidly. Wiped out

lobes, accompanied by cupped lifters, are usually

discovered due to noise or rough engine operation.

When a worn lobe is found on a camshaft, the

first reaction is to say it was “too soft”. But cast

iron camshafts are hardened as a unit, so one lobe

can’t be softer than another. If the lobes nearby

are examined, they will probably be worn on the

edges. The rest of the lobes would have eventually

failed, but one went first and tipped off the

operator that something was wrong."

Ahhh, you were talking about the cam itself. Yeah, it looks funky but that pics make it real hard to tell. When you get it out you can clean it and measure. They have to be pretty bad to make noise though.

Jeep is back together. Camshaft break in has been completed. Oil changed. Quick test drive, running great. Seems to have better acceleration and just smoother running. I can't comment on the noise if it's gone until tomorrow because I started it and went directly to 2,000 rpm and normally the noise would go away with throttle anyways.

I ended up replacing more than intended due to signs of wear.

Camshaft

Camshaft synchronizer

Head bolts

Valve stem srals

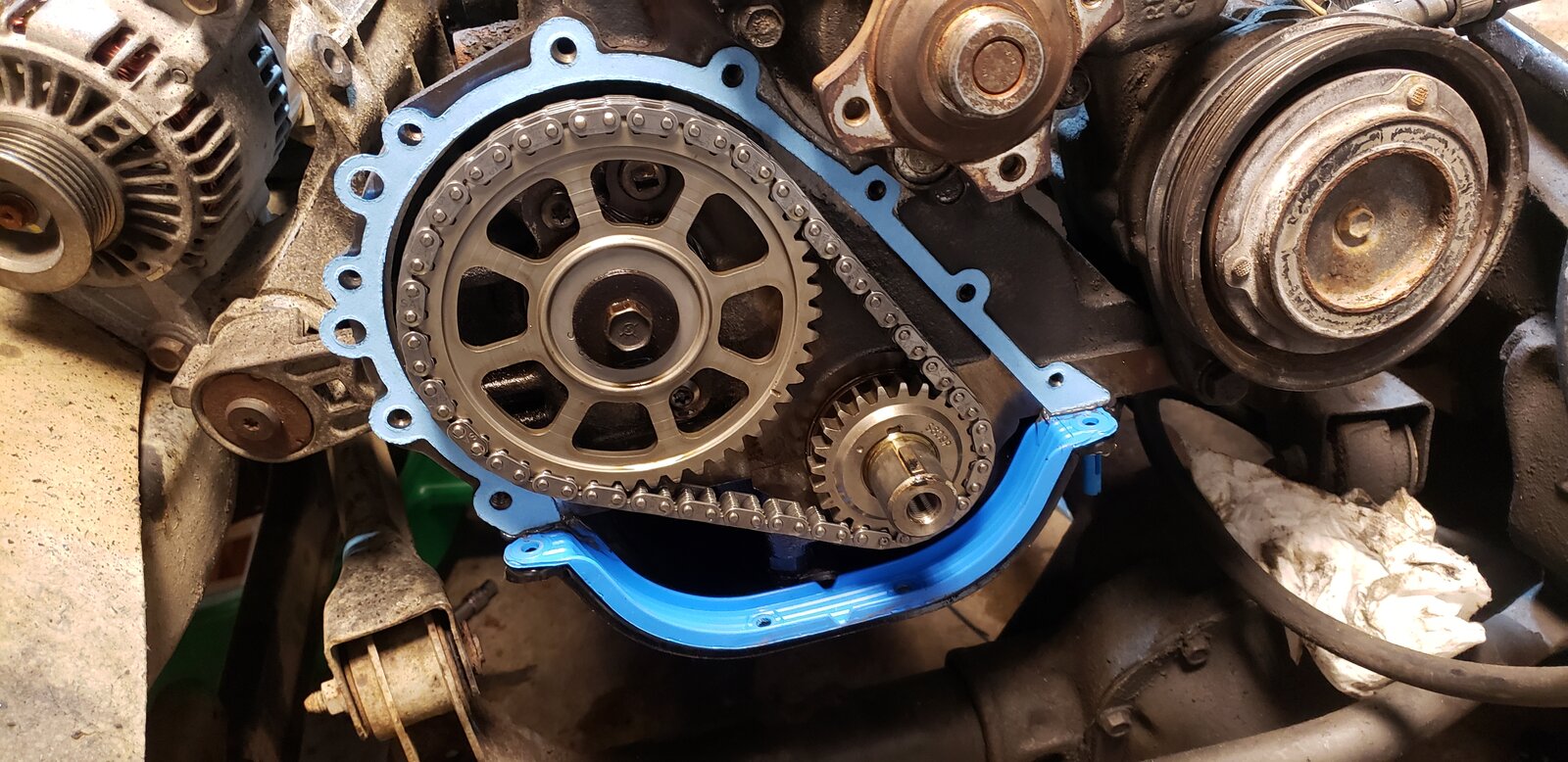

Timing set

High volume oil pump (I know, I know)

Lifters

Push rods

Rockers

Fulcrums

All gaskets associated with the change including injector o-rings

Off to a birthday party will update tomorrow with more info and a cold start video.

I ended up replacing more than intended due to signs of wear.

Camshaft

Camshaft synchronizer

Head bolts

Valve stem srals

Timing set

High volume oil pump (I know, I know)

Lifters

Push rods

Rockers

Fulcrums

All gaskets associated with the change including injector o-rings

Off to a birthday party will update tomorrow with more info and a cold start video.

Last edited:

Just got back from the party and fired the Jeep up. The sound is still 100% still present. I'm going to go bury myself now.

Joe.B

TJ Enthusiast

damn I have the same noise, my engine runs great and has great oil pressure it also has 167,000 miles on it. I'm just planning on running the engine to the ground and then stroker swapping or ls swapping probably stroker because its cheaper

sawmillman

Member

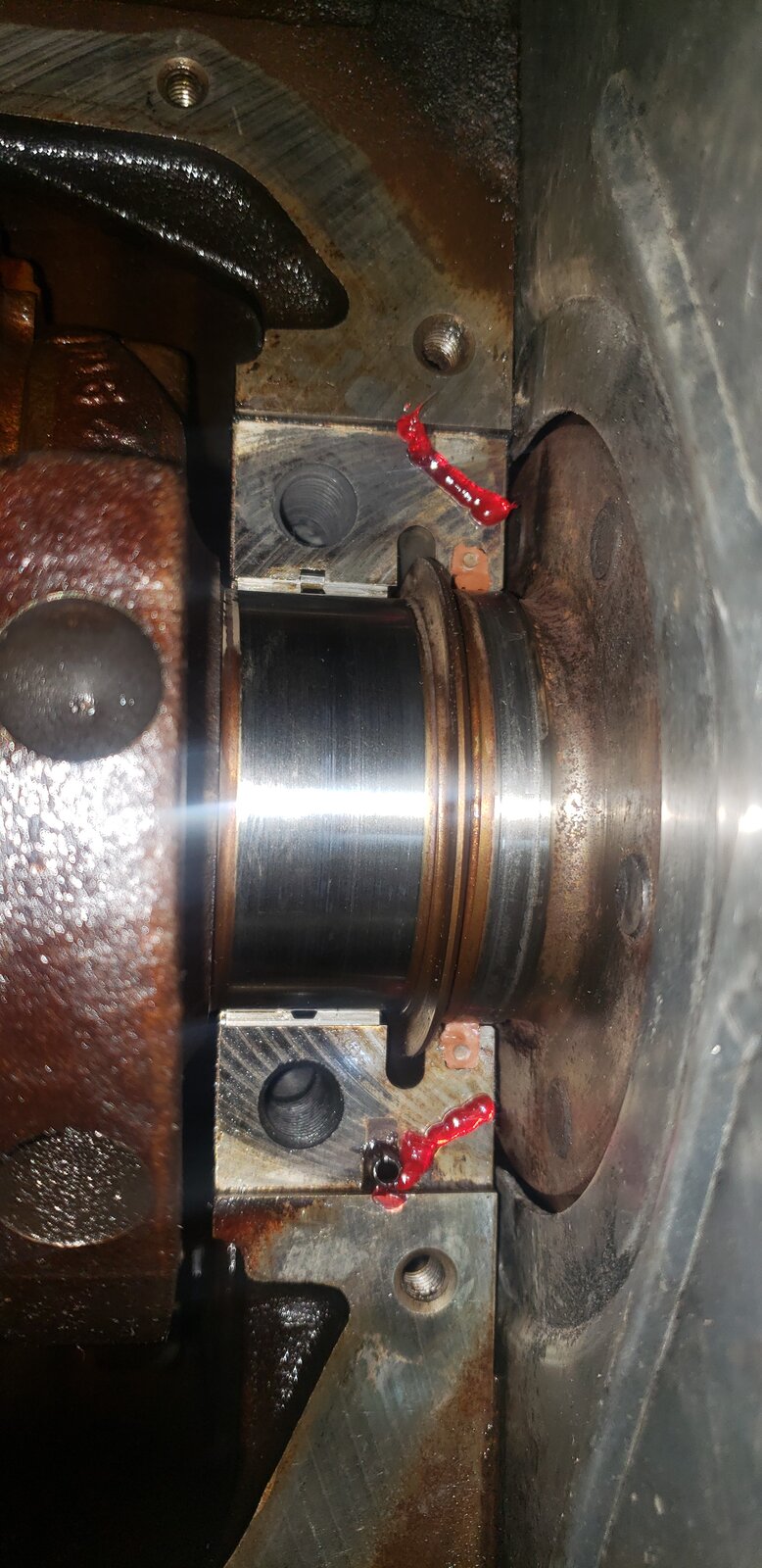

I've been following this thread since it began. I posted on it way back. I did the same thing you did with the cam and lifters with the same results. Still had the rattle. I ended up doing a in Jeep rebuild to get rid of the noise. It was minor piston slap. It ran great with the startup rattle and I'm sure it would have been fine for years.Just got back from the party and fired the Jeep up. The sound is still 100% still present. I'm going to go bury myself now.

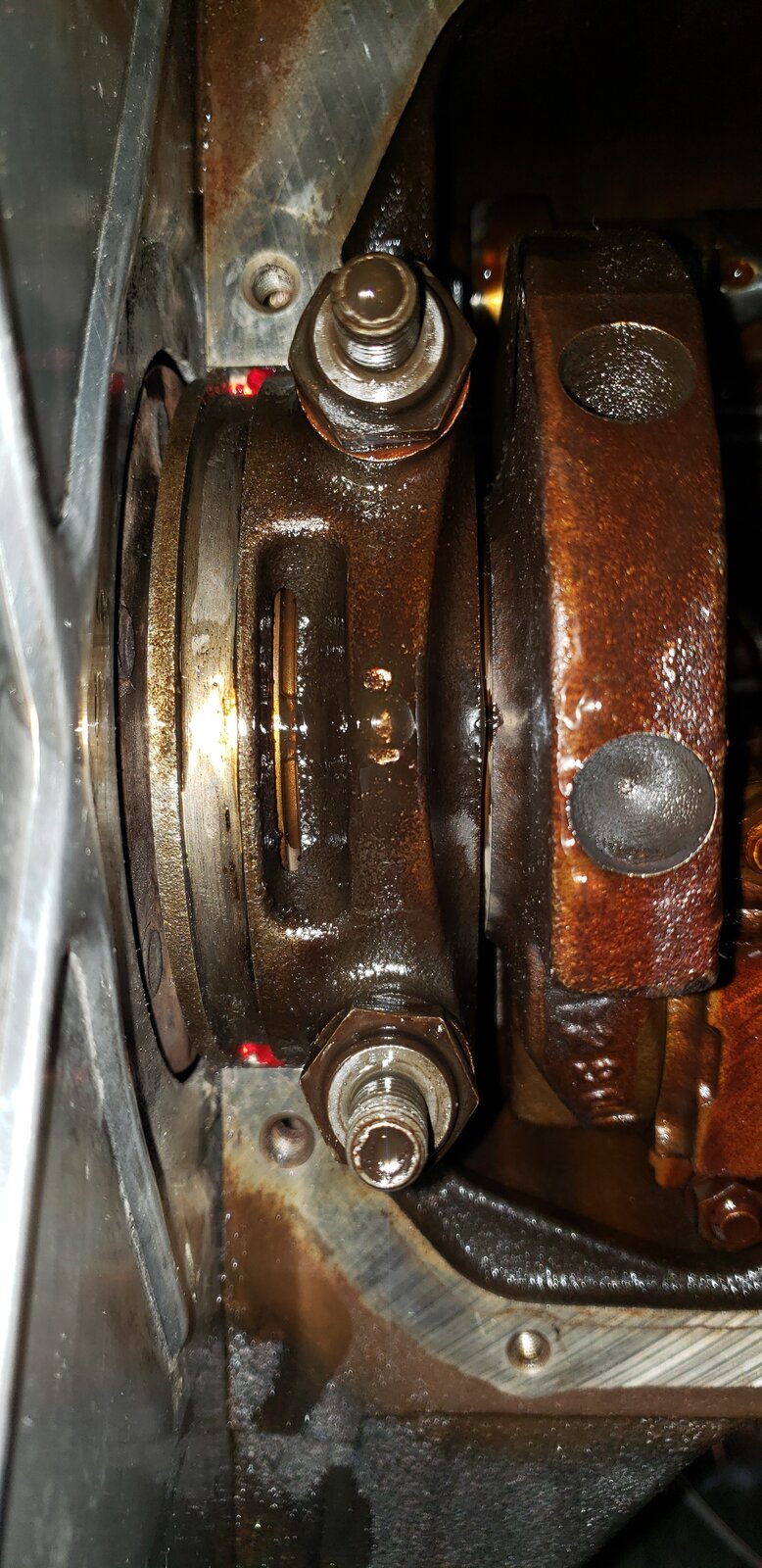

Thanks for the comment. I'm almost sure, at this point that it's piston slap. I'm just going to drive it. I'm leaking oil from the rear mail (just replaced) or the pan gasket so I'm going to fix that and just enjoy it the best I can.I've been following this thread since it began. I posted on it way back. I did the same thing you did with the cam and lifters with the same results. Still had the rattle. I ended up doing a in Jeep rebuild to get rid of the noise. It was minor piston slap. It ran great with the startup rattle and I'm sure it would have been fine for years.

Wow, very detailed with wonderful photos.Thanks for the comment. I'm almost sure, at this point that it's piston slap. I'm just going to drive it. I'm leaking oil from the rear mail (just replaced) or the pan gasket so I'm going to fix that and just enjoy it the best I can.

I replaced my RMS about 1000-1500 miles ago and applied the sealant as indicated in the photo's and no leaks and I believe one of the photo's is after I cleaned the location of the old seal multiple times (had to get my magnifying glass out due to fine amount of old gaskets was stuck). Best of luck!

Anybody have any updates? My Jeep has been running strong after the cam/lifters swap but man that start noise is really annoying me  . Also noticed it makes the noise when I release the accelerator and depress the clutch. When there is no load on the pistons/crank and it's basically 'floating'.

. Also noticed it makes the noise when I release the accelerator and depress the clutch. When there is no load on the pistons/crank and it's basically 'floating'.

Similar threads

- Replies

- 1

- Views

- 239

- Replies

- 10

- Views

- 981

- Replies

- 14

- Views

- 2,489

- Replies

- 1

- Views

- 400