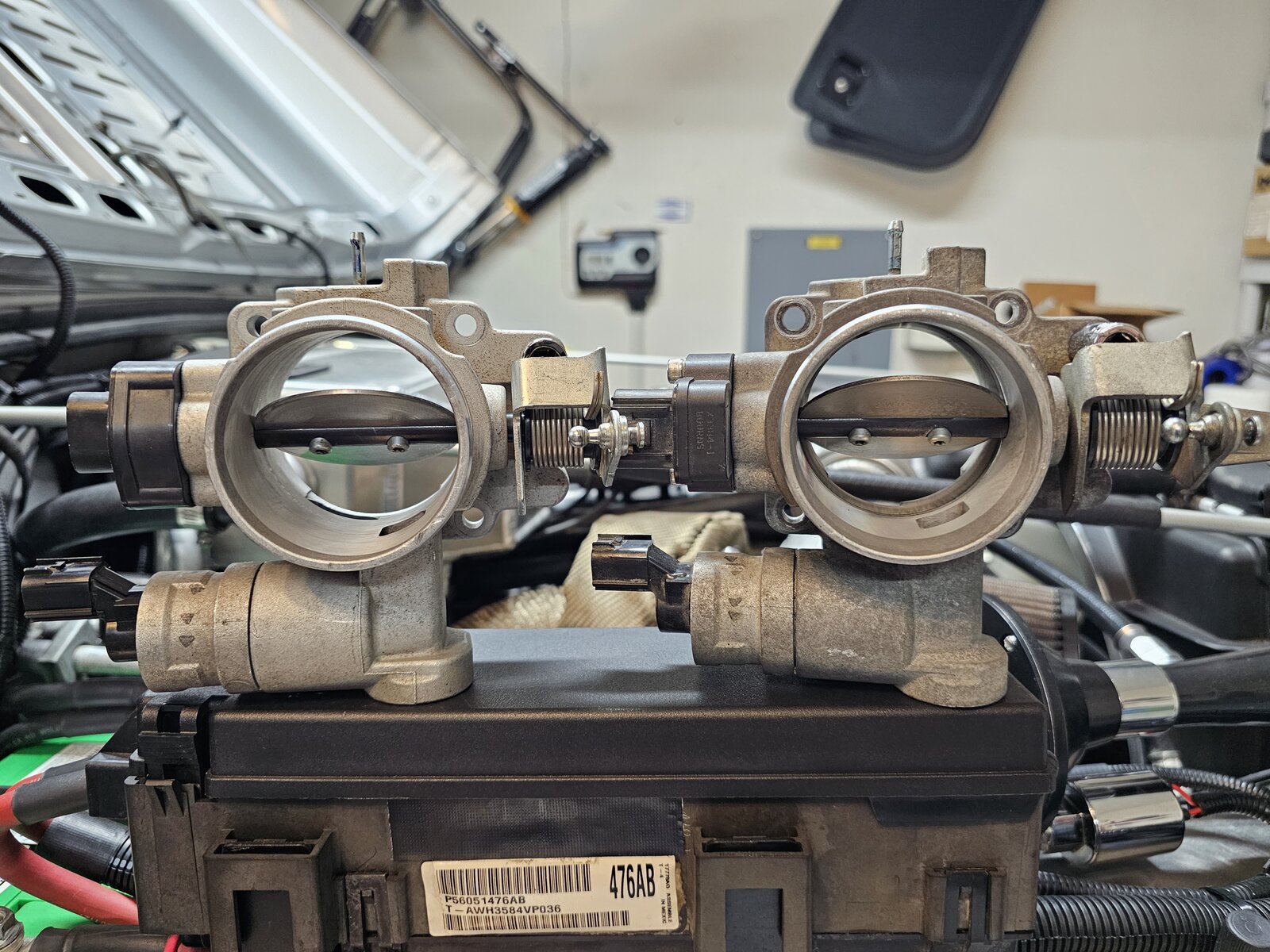

I had an extra 05-06 throttle body sitting around and I had some time the other night waiting for a cnc machine to finish a part. So I decided to bore it out and cut a new plate. The stock one is 56mm at the smallest part of the bore. I cut it out to 62mm and there is still plenty of wall thickness. I cut a new blade and used some valve lapping paste to match the parts up. Sonic cleaned it, repacked the bearings and assembled it. We'll see how it drives tomorrow.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jezza's Turbo LJ

- Thread starter Jezza

- Start date

I had an extra 05-06 throttle body sitting around and I had some time the other night waiting for a cnc machine to finish a part. So I decided to bore it out and cut a new plate. The stock one is 56mm at the smallest part of the bore. I cut it out to 62mm and there is still plenty of wall thickness. I cut a new blade and used some valve lapping paste to match the parts up. Sonic cleaned it, repacked the bearings and assembled it. We'll see how it drives tomorrow.

View attachment 444252

Hey man i just saw your build and my man you are badass dude,im now interested in doing a 6r80 swap as well if you could sell an adapter plate and the adapter for the TC, cause i have a new 700r4 sitting in my garage but 19 year old me just learned about how the ecu controls everything of course inlcuding the transmission so now im out 2k..... and since i found out about that im just gonna stick with my 42rle since i invested in a rubicrawler so for the moment ill be happy with just doing a stroker and running a standalone ecu to have more tuning power and more capability for any future plans plus you cant beat a standalone ECU

But the thing with thing is, (if thats the case) does that mean that i cant run a standalone in conjuction of the factory ecu to control only the transmission(42rle) ?

and if i cant do that then im back to square one......and ill just have to use my factory ecu and once i want to run Forced induction i need to shell out the money and ball out and go standalone and with a new transmission....yay

But i wanted to ask if you could, On where you got your wiring harness but im assuming you made it since i see and can respect on how much you know, but if you bought it premade where did you get it cause ive looked just about everywhere and only found a kit for a Haltech ECU but seems a little weird and i doesn't sit right with me on how its setup,i will post a link down below on itt

https://www.iraceautosports.com/pro...-wiring-harness-2005-2006-jeep-wrangler-4-0l/

And if you could me sell an adapter plate&tc adapter and dustshield i cant buy it now since im broke and in debt...... if possible in a few years i could do this

sorry if im all over the place with my message, Im super excited on seeing this and knowing that someone has done what i want to do, difference being that i dont have enough money or the resources to do almost the same things as yo, as well im running on 4 hours of sleep and have been awake for 19 hours and am about to go to sleep so yeah good night and i hope you can understand my reply to be able to reply me back

Peace - Dylan

I had an extra 05-06 throttle body sitting around and I had some time the other night waiting for a cnc machine to finish a part. So I decided to bore it out and cut a new plate. The stock one is 56mm at the smallest part of the bore. I cut it out to 62mm and there is still plenty of wall thickness. I cut a new blade and used some valve lapping paste to match the parts up. Sonic cleaned it, repacked the bearings and assembled it. We'll see how it drives tomorrow.

View attachment 444252

Sorry, been away for a while and just getting caught back up. This was actually something I was wondering about, will a larger throttle body make a difference in forced induction? Hopefully that isn't a stupid question.

Hey man i just saw your build and my man you are badass dude,im now interested in doing a 6r80 swap as well if you could sell an adapter plate and the adapter for the TC, cause i have a new 700r4 sitting in my garage but 19 year old me just learned about how the ecu controls everything of course inlcuding the transmission so now im out 2k..... and since i found out about that im just gonna stick with my 42rle since i invested in a rubicrawler so for the moment ill be happy with just doing a stroker and running a standalone ecu to have more tuning power and more capability for any future plans plus you cant beat a standalone ECU

But the thing with thing is, (if thats the case) does that mean that i cant run a standalone in conjuction of the factory ecu to control only the transmission(42rle) ?

and if i cant do that then im back to square one......and ill just have to use my factory ecu and once i want to run Forced induction i need to shell out the money and ball out and go standalone and with a new transmission....yay

But i wanted to ask if you could, On where you got your wiring harness but im assuming you made it since i see and can respect on how much you know, but if you bought it premade where did you get it cause ive looked just about everywhere and only found a kit for a Haltech ECU but seems a little weird and i doesn't sit right with me on how its setup,i will post a link down below on itt

https://www.iraceautosports.com/pro...-wiring-harness-2005-2006-jeep-wrangler-4-0l/

And if you could me sell an adapter plate&tc adapter and dustshield i cant buy it now since im broke and in debt...... if possible in a few years i could do this

sorry if im all over the place with my message, Im super excited on seeing this and knowing that someone has done what i want to do, difference being that i dont have enough money or the resources to do almost the same things as yo, as well im running on 4 hours of sleep and have been awake for 19 hours and am about to go to sleep so yeah good night and i hope you can understand my reply to be able to reply me back

Peace - Dylan

The 42rle is not a bad transmission if you have the right gears. Even better if it is tuned. It's got limits though. I was noticing small amounts of slip in mine when pushing the boost up.

I only made 1 adapter for the 6r80, but I have the programs so another wouldn't be difficult.

I built the harness. Most guys just hardwire the stand alone to the harness and don't use an adapter harness, but I need to be able to unplug it once a year and pass emissions.

Sorry, been away for a while and just getting caught back up. This was actually something I was wondering about, will a larger throttle body make a difference in forced induction? Hopefully that isn't a stupid question.

Not near as much as an NA engine. Pressure has the ability to push its way through restrictions, but it still causes reductions in efficiency.

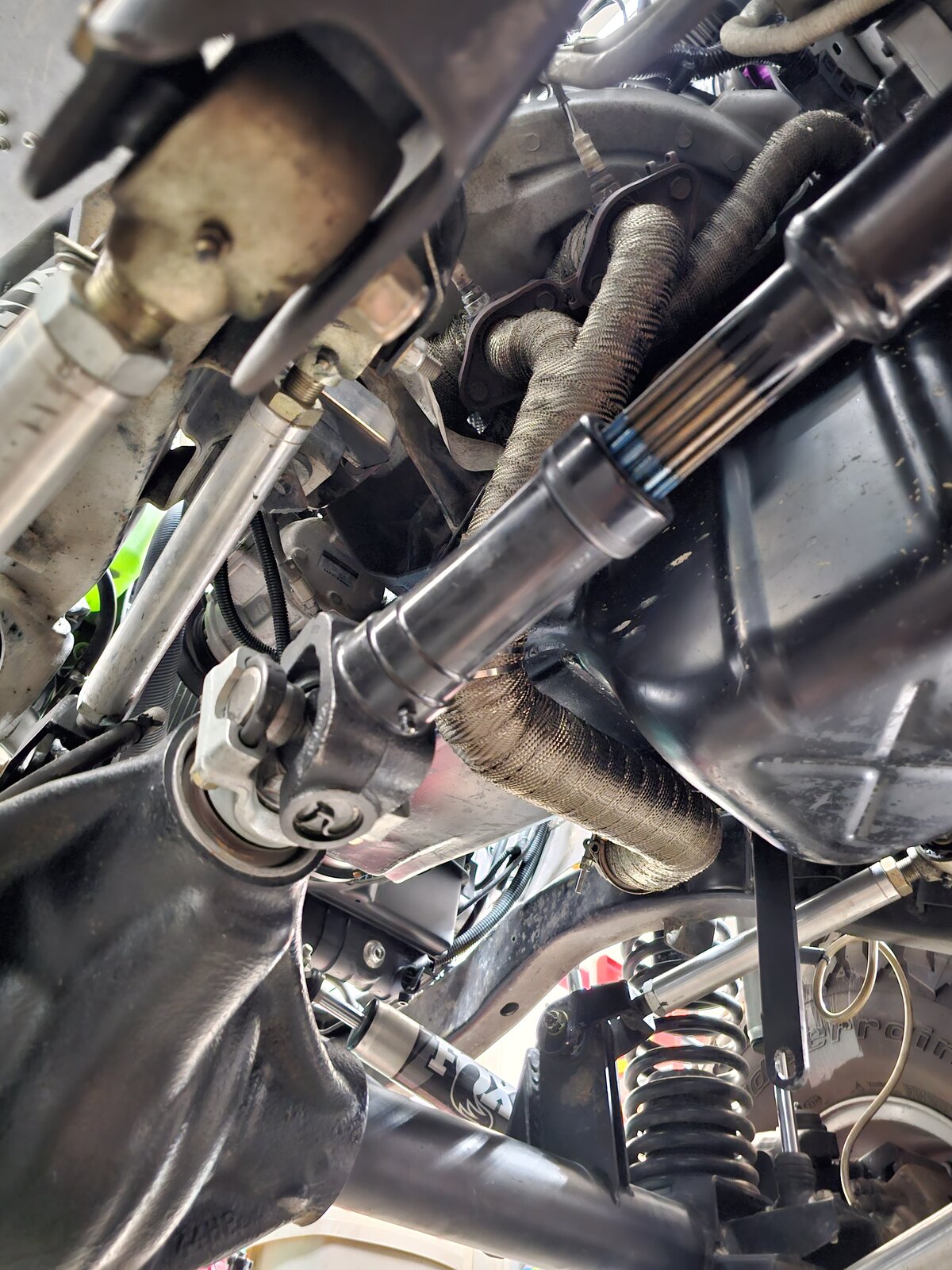

Ditched the precats. Getting things in order for the dyno soon. Hopefully

I couldn’t handle the noise, hopefully it won’t be as miserable for you.

I couldn’t handle the noise, hopefully it won’t be as miserable for you.

Yep, it's louder. Not unbearable for me, but probably more than most folks would care for. The cam sounds cooler at idle, so that's a win.

Yep, it's louder. Not unbearable for me, but probably more than most folks would care for. The cam sounds cooler at idle, so that's a win.

I failed to recall that I also had the third cat removed. It was pretty rough.

Glad it’s not so bad for you.

Last edited:

Yep, it's louder. Not unbearable for me, but probably more than most folks would care for. The cam sounds cooler at idle, so that's a win.

I hate to be this guy, but video or it didn’t happen - I wanna hear a cammed 4.0.

I would not call it cammed by any means. It has a bit of lick to it, but it's not shaking the hood. Lol.I hate to be this guy, but video or it didn’t happen - I wanna hear a cammed 4.0.

I would not call it cammed by any means. It has a bit of lick to it, but it's not shaking the hood. Lol.

I would imagine it's hard to get an I6 to "shake the hood" - im a sucker for that sound tho. I have to say, the 4.0's sound better than I expected when you put a little muffler on them - still figure I'll wind up with a diesel swap, eventually.

It is hot here, and the 4.7 is struggling to keep cool. I never had any issues with the 4.0, but I think the larger 4.7 as well as the aluminum head are challenging the system. It seems to heat up more at idle and low speed, and I noticed that at low speed the radiator outlet is 150 degrees and the coolant temp at the thermostat is 220 or so. I don't think there is enough flow at idle. I raised the RPM from 650 to 750 and that helped a little, but the radiator outlet temp is still much lower than the inlet. I took the water pump off to see if the impeller was damaged and I noticed the impeller was almost 1/8" from the housing. It's an AC Delco I put on when I changed the engine. With that much housing clearance it's no wonder there is no flow at low speed. The impeller also was super rough cast and much smaller than it could have been. It's also interesting that it has a very low pitch angle compared to other pumps I have sitting here. Feeling curious I tried to pull the impeller off and it broke. So I took some measurements and scanned a Viper pump and integrated the impeller design of that pump to the Wrangler pump. This is what I came up with.

9 blade with a 35 degree exit angle. 3/32" overbite into the center of the housing with a blade to housing clearance of 0.015" I was also able to make it almost 1/4" bigger in diameter and almost 1/8" deeper into the block. I'm interested to see how it performs.

9 blade with a 35 degree exit angle. 3/32" overbite into the center of the housing with a blade to housing clearance of 0.015" I was also able to make it almost 1/4" bigger in diameter and almost 1/8" deeper into the block. I'm interested to see how it performs.

It is hot here, and the 4.7 is struggling to keep cool. I never had any issues with the 4.0, but I think the larger 4.7 as well as the aluminum head are challenging the system. It seems to heat up more at idle and low speed, and I noticed that at low speed the radiator outlet is 150 degrees and the coolant temp at the thermostat is 220 or so. I don't think there is enough flow at idle. I raised the RPM from 650 to 750 and that helped a little, but the radiator outlet temp is still much lower than the inlet. I took the water pump off to see if the impeller was damaged and I noticed the impeller was almost 1/8" from the housing. It's an AC Delco I put on when I changed the engine. With that much housing clearance it's no wonder there is no flow at low speed. The impeller also was super rough cast and much smaller than it could have been. It's also interesting that it has a very low pitch angle compared to other pumps I have sitting here. Feeling curious I tried to pull the impeller off and it broke. So I took some measurements and scanned a Viper pump and integrated the impeller design of that pump to the Wrangler pump. This is what I came up with.

9 blade with a 35 degree exit angle. 3/32" overbite into the center of the housing with a blade to housing clearance of 0.015" I was also able to make it almost 1/4" bigger in diameter and almost 1/8" deeper into the block. I'm interested to see how it performs.

View attachment 446304

View attachment 446306

View attachment 446307

I really need to get me a 3d scanner

The aluminum head helps with detonation at the cost of more heat absorbed by the head and coolant?

That's my thoughts anyway. The heat has to go somewhere.

It is hot here, and the 4.7 is struggling to keep cool. I never had any issues with the 4.0, but I think the larger 4.7 as well as the aluminum head are challenging the system. It seems to heat up more at idle and low speed, and I noticed that at low speed the radiator outlet is 150 degrees and the coolant temp at the thermostat is 220 or so. I don't think there is enough flow at idle. I raised the RPM from 650 to 750 and that helped a little, but the radiator outlet temp is still much lower than the inlet. I took the water pump off to see if the impeller was damaged and I noticed the impeller was almost 1/8" from the housing. It's an AC Delco I put on when I changed the engine. With that much housing clearance it's no wonder there is no flow at low speed. The impeller also was super rough cast and much smaller than it could have been. It's also interesting that it has a very low pitch angle compared to other pumps I have sitting here. Feeling curious I tried to pull the impeller off and it broke. So I took some measurements and scanned a Viper pump and integrated the impeller design of that pump to the Wrangler pump. This is what I came up with.

9 blade with a 35 degree exit angle. 3/32" overbite into the center of the housing with a blade to housing clearance of 0.015" I was also able to make it almost 1/4" bigger in diameter and almost 1/8" deeper into the block. I'm interested to see how it performs.

View attachment 446304

View attachment 446306

View attachment 446307

I feel your pain on the heat - theres a company called Flow kooler that makes hi-flow water pumps, and I did an additional cooling fan mod that really helps when crawling and at low engine speed. I'm Really interested to see how the custom impeller works out, Ive heard some things about the flow koolers caveating on stock engines, I imagine with the 4.7 and the aluminum head that wont be a problem for you.

I feel your pain on the heat - theres a company called Flow kooler that makes hi-flow water pumps, and I did an additional cooling fan mod that really helps when crawling and at low engine speed. I'm Really interested to see how the custom impeller works out, Ive heard some things about the flow koolers caveating on stock engines, I imagine with the 4.7 and the aluminum head that wont be a problem for you.

I have a flow kooler water pump on my NA, iron head, stroker. So far (over 10K mi) temps are stable and good. I haven’t read or heard about cavitation issues. How would you know that‘s happening (other than over heating)? Also, I’m curious why would a stock 4.0 be more prone to it than a stroker?

How would you know that‘s happening (other than over heating)?

A video I watched showed the cavitating pump making violent sounds. And apparently there can be extra vibration.

Also, I’m curious why would a stock 4.0 be more prone to it than a stroker?

I was wondering about this as well.

Last edited:

I hate to be this guy, but video or it didn’t happen - I wanna hear a cammed 4.0.