You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Weekend Fun Build

- Thread starter fuse

- Start date

Easiest solution that is acceptable is a 1" MML. At your lift it should solve it. If you are all in for spending $$ do the SYE/ DC, but if you ever intend a TT, you will regret doing that now, wait till you are ready and do the MML now and move on.So this happened yesterday.

View attachment 116706

It became clear that I was getting unacceptable driveline vibrations after the lift. I was getting a throbbing hum from the back of the Jeep from 25 to 35 mph and again from 50 to 70 mph. The hum got louder with more throttle, quieter with less throttle, and didn't change when I changed gears, but did change with speed.

To me, that looks like the symptoms of a misaligned pinion. I did measure driveline angles before and after the lift, and I had good u-joint cancellation before the lift, poor cancellation after the lift.

I figure there are a couple of ways to deal with this:

* Drop the transfer case and possibly add a MML to reduce the driveshaft angle and move the pinion angle in the right direction.

* Get adjustable rear control arms and rotate the rear axle by about 4 degrees to get good u-joint cancellation.

* Get a SYE, DC driveshaft, adjustable rear control arms, and a rear track bar relocation bracket and redo the whole rear driveline.

I'm supposed to be leading a trail run today, so I ran out to a local parts shop and picked up the Rubicon Express TC lowering kit.

I did a test drive after the install and reproduced the same conditions and didn't get any noticeable vibration. If anything, there's maybe a tiny vibration at just over 70, but I may have imagined that, and I don't drive 70 anyway.

Hopefully the RE kit is doing the job, but I have to say I'm not impressed with it. The plastic spacers start getting crushed before you reach the torque spec on the bolts. And the washers deform before you get the bolts to torque. I replace the washers with better hardware, but the spacers are what they are.

Not recommended, but it will do as a temporary solution.

Next up is to look at adjustable control arms to see adjusting pinion angle lets me get rid of the TC drop.

MML should take care of that. If not a few extra washers on the skid to regain ujoint operating angles.

I've been thinking about that.Easiest solution that is acceptable is a 1" MML. At your lift it should solve it.

I went for the TC drop as the easiest, cheapest, and quickest fix to get the Jeep back on the road. There were also parts in stock at a local store, so between getting the parts and installing them it just took a couple of hours. That's all the time I had on Saturday to get the Jeep ready for Sunday.

I would eventually do a MML with a BL if/when I get that far in the build. So there's no reason not to try it now. Seems like it wouldn't be hard to put the MML in, remove the TC spacers, and see if that fixes the driveline vibrations.

I think I saw a MML kit somewhere that came with fan shroud relocation brackets. It might have even been from a respectable manufacturer, and IIRC it wasn't any more expensive than any other MML. That might be nice if I add a BL eventually because I could easily move the fan shroud back to the original position later.

I'll go look around and see if I can find that MML...

The aluminum blocks might be a good solution. Just $79 and uses stock motor mounts which keeps down vibrations. Then move shroud up 1”. You have to trim shroud at radiator hose. Just slit the shroud to slide it up. Ideally do with a BL and shroud can stay in stock position, no trimming, as you knowI've been thinking about that.

I went for the TC drop as the easiest, cheapest, and quickest fix to get the Jeep back on the road. There were also parts in stock at a local store, so between getting the parts and installing them it just took a couple of hours. That's all the time I had on Saturday to get the Jeep ready for Sunday.

I would eventually do a MML with a BL if/when I get that far in the build. So there's no reason not to try it now. Seems like it wouldn't be hard to put the MML in, remove the TC spacers, and see if that fixes the driveline vibrations.

I think I saw a MML kit somewhere that came with fan shroud relocation brackets. It might have even been from a respectable manufacturer, and IIRC it wasn't any more expensive than any other MML. That might be nice if I add a BL eventually because I could easily move the fan shroud back to the original position later.

I'll go look around and see if I can find that MML...

This weekend was the first trail run after the lift install. I picked a relatively easy route that I've done before so I could compare to the old suspension and so I wouldn't push the Jeep too hard in case there were any problems with the lift or my install.

The new Rancho shocks ride much nicer than the old ones. If this were mountain bike suspension, I'd describe it as well supported in the mid stroke with active bump compliance. And if I were tuning my bike shocks like this, they'd have a fair amount of low speed compression damping dialed in, with much less high speed compression damping and moderate rebound damping. I like a little more rebound damping in my mountain bike suspension, but for the Jeep this feels about right.

The OME springs are also nice. I like that the front and rear spring rates are similar, unlike the previous Moog springs. With the Moog springs, I'd roll over an obstacle with the front end, then get jounced hard when the rear end hit the same obstacle. That seemed to be a result of the Moog rear spring rate being much higher than the front spring rate. So I like the ride height and balance of the OME springs.

I don't notice anything different with the new ZJ tie rod, but I suppose that's a good thing.

The JKS track bars did their job and didn't bind up or cause any interference. I did have to reset the position of the front track bar after the run, though, because the jam nut came loose. I really leaned on it to re-tighten it, so hopefully it will stay put.

Also, the transfer case drop did it's job. There were no noticeable vibrations on the way out, which is a long drag up a 5000 ft climb. That would be the most likely condition to cause the vibrations I was having, so it seems I'm good for now.

I did order the Rough Country MML to see if installing that would let me remove the TC drop. The RC part is cheap, but I figure if @jjvw can run it for 80K, there's no way I'll be able to break it. I also ordered OE-style motor mounts and a transmission mount so I can replace the old rubber while I'm in there.

The new Rancho shocks ride much nicer than the old ones. If this were mountain bike suspension, I'd describe it as well supported in the mid stroke with active bump compliance. And if I were tuning my bike shocks like this, they'd have a fair amount of low speed compression damping dialed in, with much less high speed compression damping and moderate rebound damping. I like a little more rebound damping in my mountain bike suspension, but for the Jeep this feels about right.

The OME springs are also nice. I like that the front and rear spring rates are similar, unlike the previous Moog springs. With the Moog springs, I'd roll over an obstacle with the front end, then get jounced hard when the rear end hit the same obstacle. That seemed to be a result of the Moog rear spring rate being much higher than the front spring rate. So I like the ride height and balance of the OME springs.

I don't notice anything different with the new ZJ tie rod, but I suppose that's a good thing.

The JKS track bars did their job and didn't bind up or cause any interference. I did have to reset the position of the front track bar after the run, though, because the jam nut came loose. I really leaned on it to re-tighten it, so hopefully it will stay put.

Also, the transfer case drop did it's job. There were no noticeable vibrations on the way out, which is a long drag up a 5000 ft climb. That would be the most likely condition to cause the vibrations I was having, so it seems I'm good for now.

I did order the Rough Country MML to see if installing that would let me remove the TC drop. The RC part is cheap, but I figure if @jjvw can run it for 80K, there's no way I'll be able to break it. I also ordered OE-style motor mounts and a transmission mount so I can replace the old rubber while I'm in there.

You’re very meticulous and your interdisciplinary approach pays off.This weekend was the first trail run after the lift install. I picked a relatively easy route that I've done before so I could compare to the old suspension and so I wouldn't push the Jeep too hard in case there were any problems with the lift or my install.

View attachment 117094

The new Rancho shocks ride much nicer than the old ones. If this were mountain bike suspension, I'd describe it as well supported in the mid stroke with active bump compliance. And if I were tuning my bike shocks like this, they'd have a fair amount of low speed compression damping dialed in, with much less high speed compression damping and moderate rebound damping. I like a little more rebound damping in my mountain bike suspension, but for the Jeep this feels about right.

The OME springs are also nice. I like that the front and rear spring rates are similar, unlike the previous Moog springs. With the Moog springs, I'd roll over an obstacle with the front end, then get jounced hard when the rear end hit the same obstacle. That seemed to be a result of the Moog rear spring rate being much higher than the front spring rate. So I like the ride height and balance of the OME springs.

I don't notice anything different with the new ZJ tie rod, but I suppose that's a good thing.

The JKS track bars did their job and didn't bind up or cause any interference. I did have to reset the position of the front track bar after the run, though, because the jam nut came loose. I really leaned on it to re-tighten it, so hopefully it will stay put.

Also, the transfer case drop did it's job. There were no noticeable vibrations on the way out, which is a long drag up a 5000 ft climb. That would be the most likely condition to cause the vibrations I was having, so it seems I'm good for now.

I did order the Rough Country MML to see if installing that would let me remove the TC drop. The RC part is cheap, but I figure if @jjvw can run it for 80K, there's no way I'll be able to break it. I also ordered OE-style motor mounts and a transmission mount so I can replace the old rubber while I'm in there.

Got something to show you tomorrow...

ARB sliders are going on the Jeep.

I had to pause on the passenger side slider because I'm missing two nuts. One was missing from the parts kit in the box. The other cage nut fell off the bracket into a void on the driver's side and disappeared.

I also ordered a UCF engine skid today. I had hoped to pick up a used engine skid, but options for local parts didn't work out. Savvy would have been my first pick, but as other people may have noticed, they don't answer their phones or e-mail, and I didn't want to order something that would take weeks to show up.

Kudos to UCF for answering their phone this morning, confirming the parts in stock, estimating delivery time, promising a quick turnaround, and sending me a shipment confirmation — all within 30 minutes. The aluminum UCF skid may cost a little more than the Savvy skid, but I definitely prefer doing business with companies that have good customer service.

I had to pause on the passenger side slider because I'm missing two nuts. One was missing from the parts kit in the box. The other cage nut fell off the bracket into a void on the driver's side and disappeared.

I also ordered a UCF engine skid today. I had hoped to pick up a used engine skid, but options for local parts didn't work out. Savvy would have been my first pick, but as other people may have noticed, they don't answer their phones or e-mail, and I didn't want to order something that would take weeks to show up.

Kudos to UCF for answering their phone this morning, confirming the parts in stock, estimating delivery time, promising a quick turnaround, and sending me a shipment confirmation — all within 30 minutes. The aluminum UCF skid may cost a little more than the Savvy skid, but I definitely prefer doing business with companies that have good customer service.

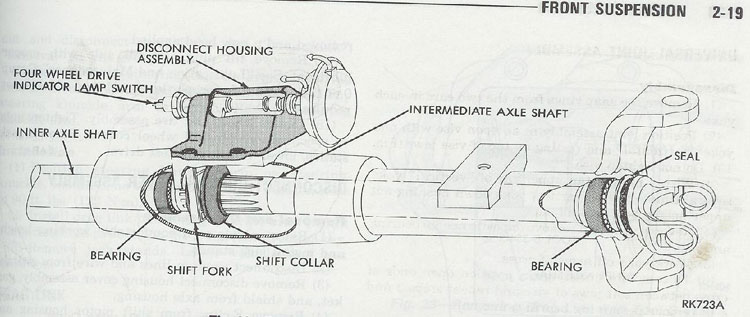

Slightly off topic, but I helped a friend install a Spartan locker in the front Dana 30 on his YJ yesterday. Dealing with the Central Axle Disconnect was a new thing for both of us, but it wasn't exactly complicated and we managed to figure out how to get the center axle shaft out of the carrier so we could remove it, and back in when we reassembled it.

(Not a YJ diagram, but that's the general idea.)

The CAD is actually kind of a nice setup when you pair it with a lunchbox locker. The front axle is disconnected in 2WD, so no clicking on turns at all. And then the front axle is connected and the locker engaged when you're in 4WD.

(Not a YJ diagram, but that's the general idea.)

The CAD is actually kind of a nice setup when you pair it with a lunchbox locker. The front axle is disconnected in 2WD, so no clicking on turns at all. And then the front axle is connected and the locker engaged when you're in 4WD.

I was busy last week. Had my mechanic weld on the Zone control arm bracket skids:

And I installed the UCF engine and transmission skid:

That's a nice upgrade. The skid itself seems well built, it fits really nicely, and the hardware was mostly easy to work with.

The one tricky bit was getting the lock washers and nuts onto the bolts inside the motor mount brackets. I just used a tiny dab of superglue to stick the hardware to my fingertip so I could fish it in, then peeled it off when it was sitting on the bolt.

That's it for upgrades for now — time to drive the Jeep!

And I installed the UCF engine and transmission skid:

That's a nice upgrade. The skid itself seems well built, it fits really nicely, and the hardware was mostly easy to work with.

The one tricky bit was getting the lock washers and nuts onto the bolts inside the motor mount brackets. I just used a tiny dab of superglue to stick the hardware to my fingertip so I could fish it in, then peeled it off when it was sitting on the bolt.

That's it for upgrades for now — time to drive the Jeep!

... I just used a tiny dab of superglue to stick the hardware to my fingertip so I could fish it in, then peeled it off when it was sitting on the bolt.

...

I hate (am proud) to say that I have done similar terrible things.

Cyanoacrylates are your friend.I hate (am proud) to say that I have done similar terrible things.

This is turning out great. I'm tempted on the UCF now! Two weeks ago I was tempted on the Rokmen. And my fave is still the Savvy, while supplies last. Will be trying to fix my derailleur today. It's something of a job I need an hour for. I've tried adjusting with the barrel adjuster at the handlebars to no avail.

Cyanoacrylates are your friend.

After you tear off your fingerprint, just use CA glue to cover the raw flesh until the skin grows back. It's the perfect problem solver!

This weekend was the big test for all the recent upgrades: springs, shocks, sliders, engine skid, control arm skids, and diff guards. Our crew went up to Big Bear and ran Gold Mountain:

The Jeep did really well! Our trail leader in a built JKU Rubi set a quick pace through the open parts of the trail, and the TJ kept up comfortably while the other Jeeps in the back were lagging. At the major obstacles, the only real problem I had was with wheel spin from the open diffs. It's clear that lockers would be a big upgrade.

The lift kept the frame and body off the rocks. I was expecting to get a couple of scratches on the engine skid and sliders, but didn't even scuff them. That's a big improvement from previous runs on more mild trails where I was hitting the transfer case skid all the time.

The only armor that saw some action were the control arm skids and the diff guards. The control arm skids took a couple of minor scuffs, which made me happy I had them. They did a good job of protecting the control arm mounts on the axle. And at one point when I had to back down from an obstacle, I tapped the rear diff guard into a rock. No harm done, just a minor scrape on the guard, which is exactly why it's there.

The bigger Jeeps on 35s and 37s went on to do John Bull, while the YJ and FJ on 33s and I called it a day. That turned out to be a wise decision because one of the JLUs grenaded a front diff and that run turned into a recovery effort.

At the end of the day, the TJ had earned its first Badge of Honor, and I had earned a cold bottle of Pliny the Elder.

As far as the build goes, I'm very happy with where the Jeep is right now. This run validated the decision to stick with 31s since the TJ did just fine compared to the rigs on 33s. The suspension is comfortable and responsive, and the armor is doing its job.

There are still some upgrades to come. Lockers would have made a big difference on the trail. And I've noticed that the crawl speed is too fast, so regearing would be good. I'd also like to get rid of the transfer case drop, but that's less of a priority since this run showed that it's high enough to stay out of the rocks.

The Jeep did really well! Our trail leader in a built JKU Rubi set a quick pace through the open parts of the trail, and the TJ kept up comfortably while the other Jeeps in the back were lagging. At the major obstacles, the only real problem I had was with wheel spin from the open diffs. It's clear that lockers would be a big upgrade.

The lift kept the frame and body off the rocks. I was expecting to get a couple of scratches on the engine skid and sliders, but didn't even scuff them. That's a big improvement from previous runs on more mild trails where I was hitting the transfer case skid all the time.

The only armor that saw some action were the control arm skids and the diff guards. The control arm skids took a couple of minor scuffs, which made me happy I had them. They did a good job of protecting the control arm mounts on the axle. And at one point when I had to back down from an obstacle, I tapped the rear diff guard into a rock. No harm done, just a minor scrape on the guard, which is exactly why it's there.

The bigger Jeeps on 35s and 37s went on to do John Bull, while the YJ and FJ on 33s and I called it a day. That turned out to be a wise decision because one of the JLUs grenaded a front diff and that run turned into a recovery effort.

At the end of the day, the TJ had earned its first Badge of Honor, and I had earned a cold bottle of Pliny the Elder.

As far as the build goes, I'm very happy with where the Jeep is right now. This run validated the decision to stick with 31s since the TJ did just fine compared to the rigs on 33s. The suspension is comfortable and responsive, and the armor is doing its job.

There are still some upgrades to come. Lockers would have made a big difference on the trail. And I've noticed that the crawl speed is too fast, so regearing would be good. I'd also like to get rid of the transfer case drop, but that's less of a priority since this run showed that it's high enough to stay out of the rocks.

This is turning out great. I'm tempted on the UCF now! Two weeks ago I was tempted on the Rokmen. And my fave is still the Savvy, while supplies last. Will be trying to fix my derailleur today. It's something of a job I need an hour for. I've tried adjusting with the barrel adjuster at the handlebars to no avail.

I would have gone with the Savvy skid if they had answered their phone or replied to e-mail. My friend put the Skid Row skid on his YJ, and I like how beefy it looks. But I have to say I'm really happy with the UCF skid. The install was easy and the fit is excellent. I'm keeping the aluminum raw and using it to post my roll call:

Will be trying to fix my derailleur today. It's something of a job I need an hour for. I've tried adjusting with the barrel adjuster at the handlebars to no avail.

I think you've got that! Let me know how that goes!

That looks sweet! Don't scratch it up now!I would have gone with the Savvy skid if they had answered their phone or replied to e-mail. My friend put the Skid Row skid on his YJ, and I like how beefy it looks. But I have to say I'm really happy with the UCF skid. The install was easy and the fit is excellent. I'm keeping the aluminum raw and using it to post my roll call:

View attachment 119891

I think you've got that! Let me know how that goes!

https://www.barnes4wd.com/Jeep-TJ-Bolt-On-Skid-Plate_p_867.html

Direct bolt on, 1/4" plate with a smooth belly to glide over obstacles, and gives you a one inch tuck compared to stock, so no crazy drive line angle changes to promote vibes. I barely scratched it on the Rubicon.

Direct bolt on, 1/4" plate with a smooth belly to glide over obstacles, and gives you a one inch tuck compared to stock, so no crazy drive line angle changes to promote vibes. I barely scratched it on the Rubicon.

I have a new project. Thanks to @06TJ35's spotting a local CL listing, I picked up a set of Savvy control arms for a reasonable price. @mrblaine may recognize them since they reportedly came off a rig that was in his shop for a mid arm upgrade.

I know these are more than I need at this point, but I figure I can use them to make some minor adjustments now and be prepared for future upgrades later. They need a little love, though.

I have three issues to deal with. I have to break the jam nuts loose. I want to break down and re-lube the joints. And the joints have some superficial rust that I need to correct.

Breaking the jam nuts loose is easier said than done. I managed to free a couple of nuts on the front uppers, but the other nuts are more stubborn. I'm soaking them in penetrating oil and lightly hammering the nuts to try to free them. I also upgraded to some bigger wrenches for the next attempt.

Breaking down the joints seems straight forward, but my snap ring pliers are crap. So I ordered some better quality tools.

The rig the control arms came from lived a stone's throw from the Pacific coast and the salt air did a job on the zinc coating on the control arms. Judging from the rust, zinc chromate doesn't do well in marine environments.

A quick test with a wire brush tells me that cleaning off the surface corrosion will be easy. I'll just wire wheel it back down to bare metal. Then I can prime and paint the external surfaces to protect them. I may use a cold galvanizing treatment on the threads and nuts, though.

All that will take a while, but I'm in no hurry.

When the new control arms are ready, I'll start with the rear set and match the stock control arm lengths, then adjust to correct rear pinion angle while keeping the axle in position.

If I can get that to work, I can do the same with the front control arms and move the front axle forward by about 1/2" to get more clearance between the track bar and tie rod.

Then I can take the Jeep to a local shop for a full alignment to verify thrust and caster angles. That should correct issues from the recent lift and set me up for a future rear drive shaft upgrade.

Meanwhile, the Jeep is running well, so I can have fun driving it.

I know these are more than I need at this point, but I figure I can use them to make some minor adjustments now and be prepared for future upgrades later. They need a little love, though.

I have three issues to deal with. I have to break the jam nuts loose. I want to break down and re-lube the joints. And the joints have some superficial rust that I need to correct.

Breaking the jam nuts loose is easier said than done. I managed to free a couple of nuts on the front uppers, but the other nuts are more stubborn. I'm soaking them in penetrating oil and lightly hammering the nuts to try to free them. I also upgraded to some bigger wrenches for the next attempt.

Breaking down the joints seems straight forward, but my snap ring pliers are crap. So I ordered some better quality tools.

The rig the control arms came from lived a stone's throw from the Pacific coast and the salt air did a job on the zinc coating on the control arms. Judging from the rust, zinc chromate doesn't do well in marine environments.

A quick test with a wire brush tells me that cleaning off the surface corrosion will be easy. I'll just wire wheel it back down to bare metal. Then I can prime and paint the external surfaces to protect them. I may use a cold galvanizing treatment on the threads and nuts, though.

All that will take a while, but I'm in no hurry.

When the new control arms are ready, I'll start with the rear set and match the stock control arm lengths, then adjust to correct rear pinion angle while keeping the axle in position.

If I can get that to work, I can do the same with the front control arms and move the front axle forward by about 1/2" to get more clearance between the track bar and tie rod.

Then I can take the Jeep to a local shop for a full alignment to verify thrust and caster angles. That should correct issues from the recent lift and set me up for a future rear drive shaft upgrade.

Meanwhile, the Jeep is running well, so I can have fun driving it.

If I tightened them and I very well may have, you won't break them loose without installing them in the rig and using a long cheater pipe on a big wrench and jumping up and down on the end of it.I have a new project. Thanks to @06TJ35's spotting a local CL listing, I picked up a set of Savvy control arms for a reasonable price. @mrblaine may recognize them since they reportedly came off a rig that was in his shop for a mid arm upgrade.

View attachment 121875

I know these are more than I need at this point, but I figure I can use them to make some minor adjustments now and be prepared for future upgrades later. They need a little love, though.

I have three issues to deal with. I have to break the jam nuts loose. I want to break down and re-lube the joints. And the joints have some superficial rust that I need to correct.

Breaking the jam nuts loose is easier said than done. I managed to free a couple of nuts on the front uppers, but the other nuts are more stubborn. I'm soaking them in penetrating oil and lightly hammering the nuts to try to free them. I also upgraded to some bigger wrenches for the next attempt.

Breaking down the joints seems straight forward, but my snap ring pliers are crap. So I ordered some better quality tools.

The rig the control arms came from lived a stone's throw from the Pacific coast and the salt air did a job on the zinc coating on the control arms. Judging from the rust, zinc chromate doesn't do well in marine environments.

A quick test with a wire brush tells me that cleaning off the surface corrosion will be easy. I'll just wire wheel it back down to bare metal. Then I can prime and paint the external surfaces to protect them. I may use a cold galvanizing treatment on the threads and nuts, though.

All that will take a while, but I'm in no hurry.

When the new control arms are ready, I'll start with the rear set and match the stock control arm lengths, then adjust to correct rear pinion angle while keeping the axle in position.

If I can get that to work, I can do the same with the front control arms and move the front axle forward by about 1/2" to get more clearance between the track bar and tie rod.

Then I can take the Jeep to a local shop for a full alignment to verify thrust and caster angles. That should correct issues from the recent lift and set me up for a future rear drive shaft upgrade.

Meanwhile, the Jeep is running well, so I can have fun driving it.