It's a clever trick to be aware of, though slightly different than what I described above. Pics are buried in my build thread. Basically the bump stops are set for something other than the compressed shock. That would leave some amount of unused and unusable travel in shock. Then spacers are added to the stock shock mounts to further compress the shock to match the bump stops. This will add some down travel. If there is ever a good use for bar pin eliminators, this is it.Alex, I'd do the trick that Josh did on his and raise the upper mount an inch to gain another inch of up, cause it looks like you still have tire clearance. More uptravel always trumps down IMO.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Track bar and tie rod: What hits, what doesn't?

- Thread starter StG58

- Start date

I'm a bit lost here. Are you saying there is a way to gain clearance without welding?Alex, I'd do the trick that Josh did on his and raise the upper mount an inch to gain another inch of up, cause it looks like you still have tire clearance. More uptravel always trumps down IMO.

Raising the mount doesn't look overly difficult. Maybe in the future I can get it all mocked up and have a mobile welder come out and burn it in place. For now I suppose I will move the axle so I can get more more clearance and look into raising the mount in the future.

It's a clever trick to be aware of, though slightly different than what I described above. Pics are buried in my build thread. Basically the bump stops are set for something other than the compressed shock. That would leave some amount of unused and unusable travel in shock. Then spacers are added to the stock shock mounts to further compress the shock to match the bump stops. This will add some down travel. If there is ever a good use for bar pin eliminators, this is it.

I'll look through your build later today and see what I can find. Thanks for the input.

I'm a bit lost here. Are you saying there is a way to gain clearance without welding?

Yes, with a caveat. It only works if you are "in between" shock sizes. It worked with my previous OME shocks which had unusual measurements and travels. To do this effectively, you need to understand what you existing bump stops are set for, and you should know what your minimum required extension is for something other than the compressed shock. And you need to know your current travel bias is and predict what another shock setup will give you.

Raising the mount doesn't look overly difficult. Maybe in the future I can get it all mocked up and have a mobile welder come out and burn it in place. ...

....

It isn't difficult. If you understand bump stops then you can move shock mounts around in whichever direction might be of benefit.

Here's what I'm picturing, get a chunk of 2.5" black pipe one inch long and a chunk of 1/4" flat plate. cut the flat plate to cap off one end of the pipe. Drill the proper size hole for the shock stud, then take a hole saw and hog out the upper mount hole big enough for the shock to pass through. Weld your new cap on top and bingo, 1" raised upper mount.

That's just about what I did.Here's what I'm picturing, get a chunk of 2.5" black pipe one inch long and a chunk of 1/4" flat plate. cut the flat plate to cap off one end of the pipe. Drill the proper size hole for the shock stud, then take a hole saw and hog out the upper mount hole big enough for the shock to pass through. Weld your new cap on top and bingo, 1" raised upper mount.

@Alex01, let me verify the pipe ID and I'll see what I have in the welding shop for scrap. Might be able to fab 2 up for you, then all you'll need is someone to burn them in to your upper mounts. I could do that for you but it would probably be cheaper (gas here and back home in a jeep, lol!) to get a mobile guy to weld them on for you locally.

My uppers are 1.375" above the stock mount as determined by the shock and the existing bump stop extension.

Yeah, @Alex01 will need to do some full bump measuring to see how tall he can get away with.

That would be awesome. Once I find a bit of time I'll push back the axle a bit for clearance then figure out how tall I can get away with.@Alex01, let me verify the pipe ID and I'll see what I have in the welding shop for scrap. Might be able to fab 2 up for you, then all you'll need is someone to burn them in to your upper mounts. I could do that for you but it would probably be cheaper (gas here and back home in a jeep, lol!) to get a mobile guy to weld them on for you locally.

As far as welding goes I can get a mobile guy out here. Then again I'll have to pick up the mounts from you anyways

That would be awesome. Once I find a bit of time I'll push back the axle a bit for clearance then figure out how tall I can get away with.

As far as welding goes I can get a mobile guy out here. Then again I'll have to pick up the mounts from you anyways

I can always throw them in a flat rate box and mail them to you. You'd be ruined if you came to my shop with 2 post lifts, air, welder, tools, etc. You'll never want to be on your back on cement again, lol!

That sure does sound nice. Maybe one day I can have one for myself. Or just moon light at a shop lol.I can always throw them in a flat rate box and mail them to you. You'd be ruined if you came to my shop with 2 post lifts, air, welder, tools, etc. You'll never want to be on your back on cement again, lol!

Back to the topic at hand...I'm running a JKS Trackbar, Dana 44 front axle, ZJ steering, and a set of 2" lift springs from OME. I the JJ on the JKS TB just squeaks by the Spring Perch. I have about a half inch of clearance to the diff cover (factory covers)

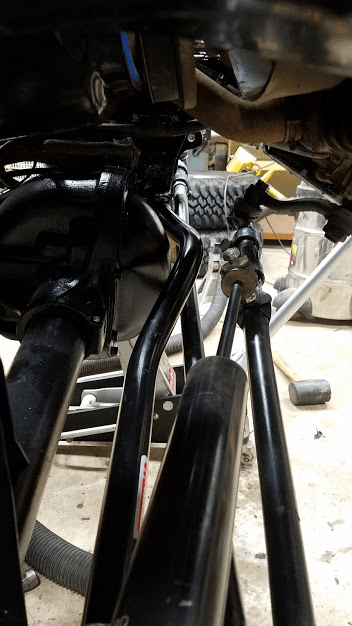

Full stuff pass side. Shows Tie Rod clearance

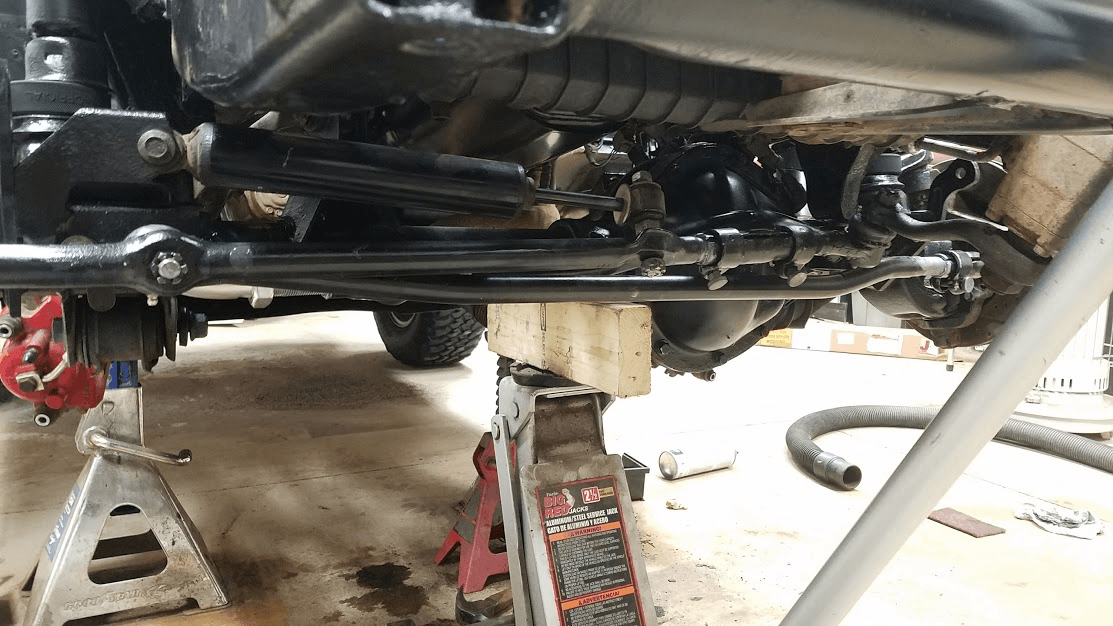

Full Stuff Driver side, Track Bar Clearance to Diff

Same axle position, clearance to spring perch.

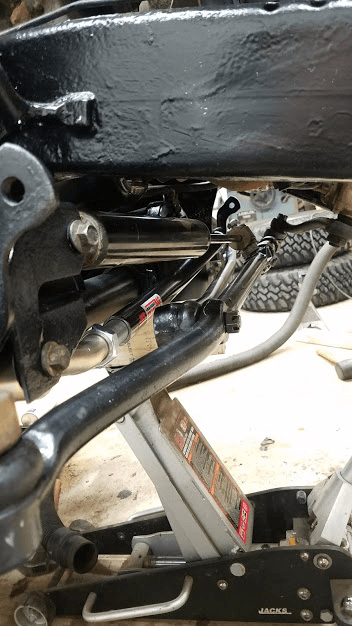

Not a great picture, but this is full bump.

Full stuff pass side. Shows Tie Rod clearance

Full Stuff Driver side, Track Bar Clearance to Diff

Same axle position, clearance to spring perch.

Not a great picture, but this is full bump.

Last edited:

That is the front of your spring perch it is squeaking by and you can clip that corner off at a 45 degree angle and plate it back in for more room if you ever need it.Back to the topic at hand...I'm running a JKS Trackbar, Dana 44 front axle, ZJ steering, and a set of 2" lift springs from OME. I the JJ on the JKS TB just squeaks by the swaybar link mount. I have about a half inch of clearance to the diff cover (factory covers)

Full stuff pass side. Shows Tie Rod clearance

View attachment 70754

Full Stuff Driver side, Track Bar Clearance to Diff

View attachment 70755

Same axle position, clearance to swaybar link bracket

View attachment 70756

Not a great picture, but this is full bump.

View attachment 70758

View attachment 70757

I took a peak at my arms. I really don't have much adjustment towards the rear to go anymore. It looks like the jks solved the issue by bending around the diff cover. I may need to pick up the jks to fix my issue. Thanks for the pictures.Back to the topic at hand...I'm running a JKS Trackbar, Dana 44 front axle, ZJ steering, and a set of 2" lift springs from OME. I the JJ on the JKS TB just squeaks by the swaybar link mount. I have about a half inch of clearance to the diff cover (factory covers)

Full stuff pass side. Shows Tie Rod clearance

View attachment 70754

Full Stuff Driver side, Track Bar Clearance to Diff

View attachment 70755

Same axle position, clearance to swaybar link bracket

View attachment 70756

Not a great picture, but this is full bump.

View attachment 70758

View attachment 70757

Haha...Oh yeah. Thanks. Good to know about being able to cut it. I might do that, just because its so close.That is the front of your spring perch it is squeaking by and you can clip that corner off at a 45 degree angle and plate it back in for more room if you ever need it.

I took a peak at my arms. I really don't have much adjustment towards the rear to go anymore. It looks like the jks solved the issue by bending around the diff cover. I may need to pick up the jks to fix my issue. Thanks for the pictures.

I think the Currie has an offset JJ frame end that moves it another 5/8" or so forward if you really need the extra clearance. I don't know how you can tell which you'll need...

I cycled my suspension without the shocks in. The max compressed length I can stuff in without modifications would be 14.5.

Was that full flex? What size tire?I cycled my suspension without the shocks in. The max compressed length I can stuff in without modifications would be 14.5.

View attachment 71410View attachment 71411

Was that full flex? What size tire?

That is as high as I can get the passanger side tire. The driver is still limited by the trackbar but I orderes one with more clearance.

Tires are 35s. Fenders are metalclaok overline.

What was the limit to up? The tire? If so, where did it hit? Is 14.5" the distance between shock mounts?That is as high as I can get the passanger side tire. The driver is still limited by the trackbar but I orderes one with more clearance.

Tires are 35s. Fenders are metalclaok overline.