This took me 2 hrs, 4 milwaukee blades and 2 batteries to get out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tworley build

View attachment 493801had to walk

This took me 2 hrs, 4 milwaukee blades and 2 batteries to get out.

Oh man, I know this one. I had a similar issue with a seized upper control arm, axle side, bushing. I had to try different tools and walk away a couple times. 2+ hours later, it was done. It was a good feeling to get it done, but not a good feeling getting it done!

Oh man, I know this one. I had a similar issue with a seized upper control arm, axle side, bushing. I had to try different tools and walk away a couple times. 2+ hours later, it was done. It was a good feeling to get it done, but not a good feeling getting it done!

There were a few swear words tonight

It's your Jeep, only better!

It's your Jeep, only better!

Technically...they're not wrong. Its better now with the new bushing!

Brianj5600

TJ Expert

I have had a few '60s and '70s cars that had issues like that. The hardened sleeves and bolts become a solid piece. A cut off wheel will make quick work if you have room.

I have had a few '60s and '70s cars that had issues like that. The hardened sleeves and bolts become a solid piece. A cut off wheel will make quick work if you have room.

A 4.5" cutoff wheel on my grinder wouldn't fit since the trackbar was still in the way. This was done with a hackzall.

Technically...they're not wrong. Its better now with the new bushing!

Would you have gone with another company for your control arms and track bars ?

Do you like em ? Apart from the joys that you had from removing that old bushing on that track bar

Would you have gone with another company for your control arms and track bars ?

Do you like em ? Apart from the joys that you had from removing that old bushing on that track bar

I didn't know any better 10 years ago when I bought these. The duroflex joints were fairly new, alot of people had them. So I jumped on the bandwagon.

I've replaced all the joints after 80-85k miles which were causing severe axle wrap, enough to destroy a few centering yokes in my rear driveshaft. New joints, they obviously work, but there are better joints.

The biggest difference I think which warrants the johhny joint is the jj's ability to have the ball move around within the bushing. Metalcloak is bonded and relies on grease so the bushing can rotate in the barrel. If the grease dries out, the bushing binds against the barrel and the spherical ball begins to tear up the joint (which was my experience).

As for trackbars-- Handsdown I'd go currie. Hiem joints don't belong on a trackbar. An offset barrel also helps with clearance

Last edited:

Slow progress, but the trackbar is ready to go back in.

![20240124_172403[1].jpg 20240124_172403[1].jpg](https://wranglertjforum.com/attachments/20240124_172403-1-jpg.494325/)

![20240124_171856[1].jpg 20240124_171856[1].jpg](https://wranglertjforum.com/attachments/20240124_171856-1-jpg.494326/)

Slow progress on steering, but progress nonetheless

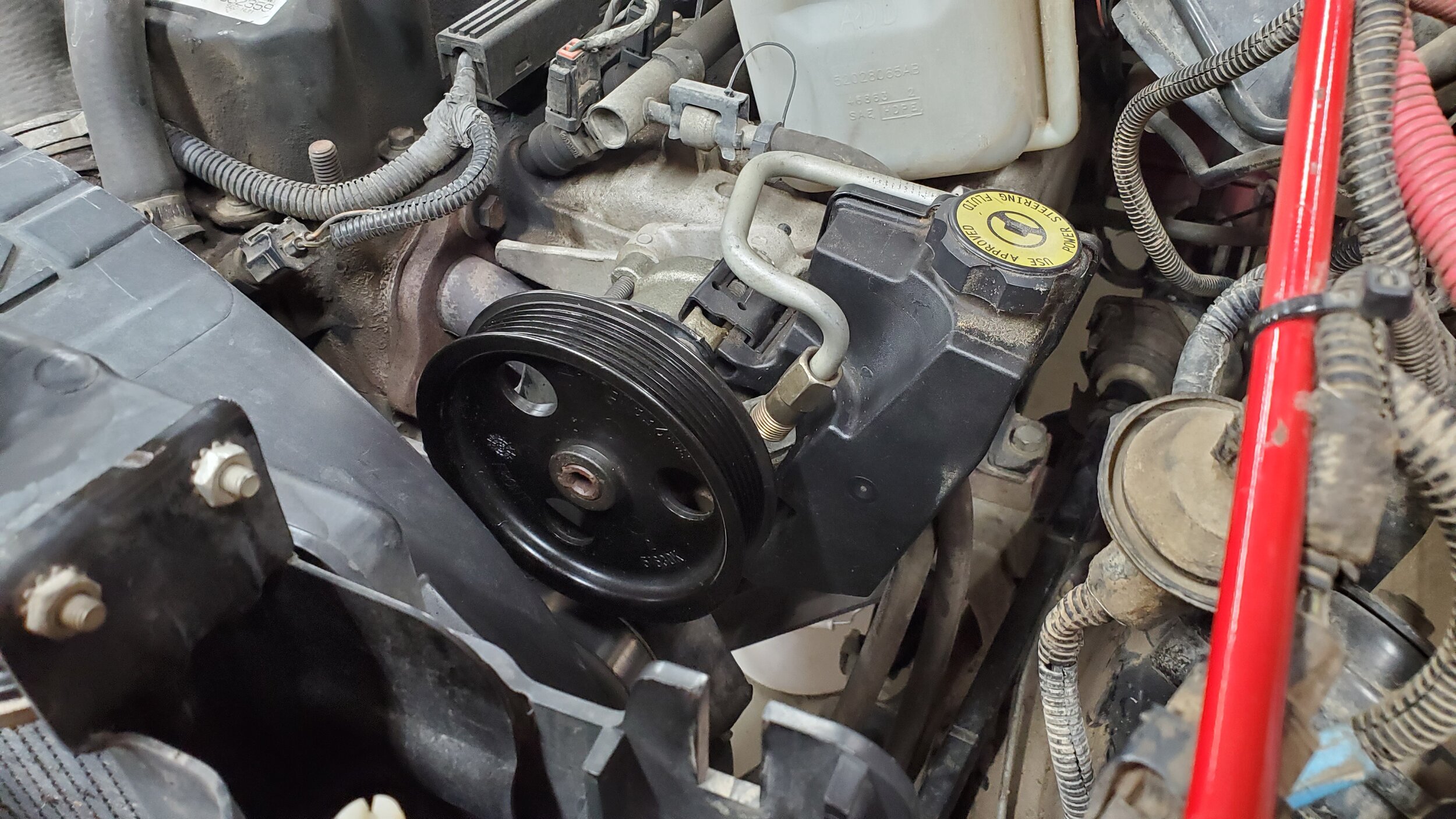

On the spare pump, i removed the fitting and drilled it out to 9/64" to increase flow and shimmed the spring to try and up the pressure. We'll see how this goes...

The tapped steering box is in and replaced the lower steering shaft with a spare I had. The steering cooler is officially mounted with loctite 545 on the fittings and 271 for the mounting screws. The passenger side -8 is routed from the box to the cooler.

And the ram and fittings are mated together with loctite 609.

I need to install the -6 line from the cooler to the stock reservoir, the fittings on the box to the ram, and build my drag link mount.

On the spare pump, i removed the fitting and drilled it out to 9/64" to increase flow and shimmed the spring to try and up the pressure. We'll see how this goes...

The tapped steering box is in and replaced the lower steering shaft with a spare I had. The steering cooler is officially mounted with loctite 545 on the fittings and 271 for the mounting screws. The passenger side -8 is routed from the box to the cooler.

And the ram and fittings are mated together with loctite 609.

I need to install the -6 line from the cooler to the stock reservoir, the fittings on the box to the ram, and build my drag link mount.

Slow progress on steering, but progress nonetheless

On the spare pump, i removed the fitting and drilled it out to 9/64" to increase flow and shimmed the spring to try and up the pressure. We'll see how this goes...

View attachment 497411

View attachment 497403

View attachment 497407

The tapped steering box is in and replaced the lower steering shaft with a spare I had. The steering cooler is officially mounted with loctite 545 on the fittings and 271 for the mounting screws. The passenger side -8 is routed from the box to the cooler.

View attachment 497480

View attachment 497484

View attachment 497481

And the ram and fittings are mated together with loctite 609.

View attachment 497482

I need to install the -6 line from the cooler to the stock reservoir, the fittings on the box to the ram, and build my drag link mount.

Very nice work. I’m interested in seeing how drilling out the power steering line to 9/64” helps with the pressure.

The jeep is still on jackstands, but I am joining the ever-growing auto swap group on WTJF! I spotted this TJ at the local u-pull&pay and @hosejockey61 graciously picked up the 32rh for me while I was at work.

I still need a few items and have ordered several parts already. Its all very exciting! To make it work with the savvy ua will be a challenge. Savvy never made a skid setup for the early automatics. From my understanding, its going to require a separate, stand alone cross-member as the 32rh is much shorter in lenth. we'll cross that bridge soon enough though.

I still need a few items and have ordered several parts already. Its all very exciting! To make it work with the savvy ua will be a challenge. Savvy never made a skid setup for the early automatics. From my understanding, its going to require a separate, stand alone cross-member as the 32rh is much shorter in lenth. we'll cross that bridge soon enough though.

The jeep is still on jackstands, but I am joining the ever-growing auto swap group on WTJF! I spotted this TJ at the local u-pull&pay and @hosejockey61 graciously picked up the 32rh for me while I was at work.

View attachment 499278

View attachment 499280

I still need a few items and have ordered several parts already. Its all very exciting! To make it work with the savvy ua will be a challenge. Savvy never made a skid setup for the early automatics. From my understanding, its going to require a separate, stand alone cross-member as the 32rh is much shorter in lenth. we'll cross that bridge soon enough though.

Not ONLY does @tworley have friends, but has friends who will pull entire transmissions as favors.

I need to tell my friends to step it up, they're under the bar.

Not ONLY does @tworley have friends, but has friends who will pull entire transmissions as favors.

I need to tell my friends to step it up, they're under the bar.

We are pretty fortunate to have a great group around CO (despite what some people say about the krew).

The jeep is still on jackstands, but I am joining the ever-growing auto swap group on WTJF! I spotted this TJ at the local u-pull&pay and @hosejockey61 graciously picked up the 32rh for me while I was at work.

View attachment 499278

View attachment 499280

I still need a few items and have ordered several parts already. Its all very exciting! To make it work with the savvy ua will be a challenge. Savvy never made a skid setup for the early automatics. From my understanding, its going to require a separate, stand alone cross-member as the 32rh is much shorter in lenth. we'll cross that bridge soon enough though.

Will you need to regear the axles?

Will you need to regear the axles?

Ill give it a go with the 5.13s. If I remember right I'll be about 3k RPM at 60mph. Since the jeep is not a DD I'm less worried the gearing.

Ill give it a go with the 5.13s. If I remember right I'll be about 3k RPM at 60mph. Since the jeep is not a DD anymore, I'm less worried it.

32rh/33.875"/5.13=3053rpm @ 60mph

32rh/33.875"/5.13=3816rpm @ 75mph