You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trail_Krawler & Trail_Willys

- Thread starter kmas0n

- Start date

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Break out the angle grinder

I'm thinking I'll relocated it on top of the factory mount... The two square nubs. Should be plenty of roomBreak out the angle grinder

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

It looks like of you hadn't mounted it to the rear of the pumpkin it would be fine. Do you not want more link separation? If were on top and centered like the savvy 3link I don't see any interferenceI'm thinking I'll relocated it on top of the factory mount... The two square nubs. Should be plenty of room

The upper-link just needs to move towards the driver's side. I'm thinking about 2 inches or so. How much separation do I need? I have 8 at the frame and 9 at the axle. The upper and lower links are near parallel and the same length.It looks like of you hadn't mounted it to the rear of the pumpkin it would be fine. Do you not want more link separation? If were on top and centered like the savvy 3link I don't see any interference

Ok, so my solution is simple, I kept the driver side of the mount, and relocated the upper link to the other side of it, I'll make a new driver side mount (unless someone thinks single shear is enough  ) This should free up plenty of room for the exhaust too. Once the pan comes in I'll be able to check clearance for the truss. its going to be tight and may require a cutoff wheel and welder (My two favorite tools). Again, these are all at the extreme limits of travel, such as bottoming out hard off a jump, but we certainly don't want the oil pan being the hard bump.

) This should free up plenty of room for the exhaust too. Once the pan comes in I'll be able to check clearance for the truss. its going to be tight and may require a cutoff wheel and welder (My two favorite tools). Again, these are all at the extreme limits of travel, such as bottoming out hard off a jump, but we certainly don't want the oil pan being the hard bump.

If you have enough clearance on the frame side, I think that looks good. Also appears that you have a little more clearance under that part of the mount.Ok, so my solution is simple, I kept the driver side of the mount, and relocated the upper link to the other side of it, I'll make a new driver side mount (unless someone thinks single shear is enough) This should free up plenty of room for the exhaust too. Once the pan comes in I'll be able to check clearance for the truss. its going to be tight and may require a cutoff wheel and welder (My two favorite tools). Again, these are all at the extreme limits of travel, such as bottoming out hard off a jump, but we certainly don't want the oil pan being the hard bump.

View attachment 270023

Before you burn it in, if you have not done so check your clearance at full articulation (full stuff on one side while at full droop on the other) both ways. If that works I’d say you are golden.

Frame side is good, I wish I had the exhaust headers in, that would help confirm placement, so I'll just go with "as far away as possible" from them. I've fully flexed it and everything clears fine.If you have enough clearance on the frame side, I think that looks good. Also appears that you have a little more clearance under that part of the mount.

Before you burn it in, if you have not done so check your clearance at full articulation (full stuff on one side while at full droop on the other) both ways. If that works I’d say you are golden.

In the interest of future proofing, I can remove an inch of bump stop extension for more up travel.

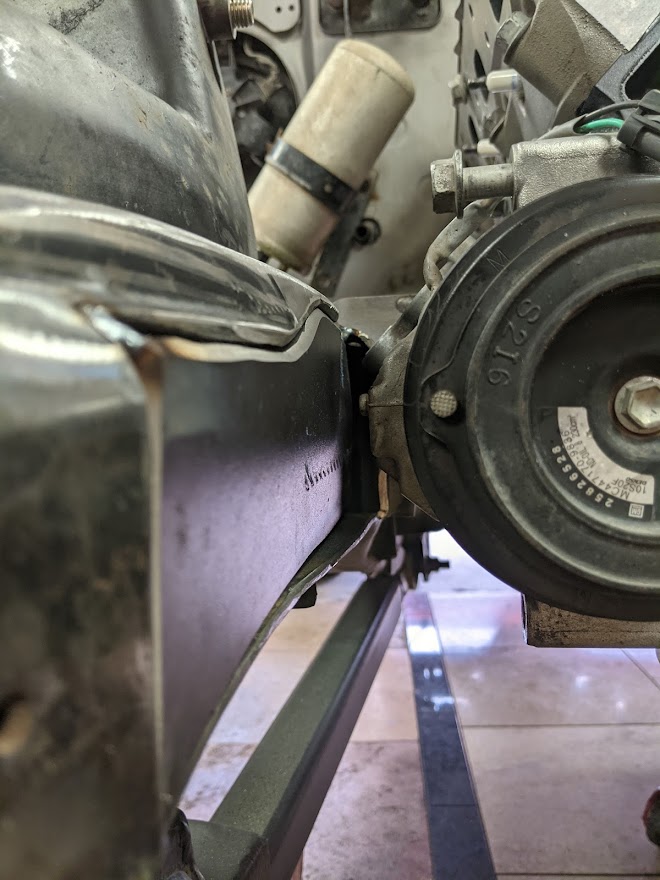

On to the next bit of frame modification. The vortec truck engines have thier ac compressor mounted low on the passenger side. The frame of the tj is too narrow and has to be notched. They make ac compressor relocation kits, but that's for people who are afraid of cutting and welding thier frames. I really can't find any pics online so this is what I've come up with...

My thoughts are cut a transectional rectangle slice out, flip it, and weld it back in. The better my rectangle, the better the notch. The outie will become an innie.

Anyone have any thoughts? Pictures? What have others done?

Edit: despite being diligent and very careful, I was unable to make this plan work and instead used a 0.25 patch panel

My thoughts are cut a transectional rectangle slice out, flip it, and weld it back in. The better my rectangle, the better the notch. The outie will become an innie.

Anyone have any thoughts? Pictures? What have others done?

Edit: despite being diligent and very careful, I was unable to make this plan work and instead used a 0.25 patch panel

Last edited:

Have you looked at Tox's thread? I thought he did something along these lines.On to the next bit of frame modification. The vortec truck engines have thier ac compressor mounted low on the passenger side. The frame of the tj is too narrow and has to be notched. They make ac compressor relocation kits, but that's for people who are afraid of cutting and welding thier frames. I really can't find any pics online so this is what I've come up with...

View attachment 270126

My thoughts are cut a transectional rectangle slice out, flip it, and weld it back in. The better my rectangle, the better the notch. The outie will become an innie.

Anyone have any thoughts? Pictures? What have others done?

I've read it a while back, but I thought he relocated his higher. I may be wrongHave you looked at Tox's thread? I thought he did something along these lines.

He clearanced that side for something, I thought.I've read it a while back, but I thought he relocated his higher. I may be wrong

Tox' thread is great, but it's 70 pages long and I think there are at least two of them. It takes forever to find stuff!He clearanced that side for something, I thought.

he starts talking about it on this pageTox' thread is great, but it's 70 pages long and I think there are at least two of them. It takes forever to find stuff!

https://wranglertjforum.com/threads...que-a-streetable-lj-engine-swap.36240/page-15

Marked it here

https://wranglertjforum.com/threads...a-streetable-lj-engine-swap.36240/post-754948

Thank you!he starts talking about it on this page

https://wranglertjforum.com/threads...que-a-streetable-lj-engine-swap.36240/page-15

Marked it here

https://wranglertjforum.com/threads...a-streetable-lj-engine-swap.36240/post-754948

Your search skills are vastly superior to mine!

I'm soon to be doing the same thing so I'm trying to get all the info I can.Thank you!

Your search skills are vastly superior to mine!

This is what I came up with for the notch for the AC compressor.

First used a laser level to try to get the lines as straight as possible, and to make the cutout a rectangle.

This is the slice I cut out, a few different angles...

Put the engine back in, and test fit some more...

The fittings were still going to interfere with the frame so I cut a slit in the filler panel, put it in a vice and smacked it until I had a 0.25" channel.

Then made a little filler piece for the rear, welded everything up, painted with Steel-it.

First used a laser level to try to get the lines as straight as possible, and to make the cutout a rectangle.

This is the slice I cut out, a few different angles...

Put the engine back in, and test fit some more...

The fittings were still going to interfere with the frame so I cut a slit in the filler panel, put it in a vice and smacked it until I had a 0.25" channel.

Then made a little filler piece for the rear, welded everything up, painted with Steel-it.

After reading the fantastic review of the ORO Swayloc from @Mr. Bills I jumped on Polyperformance and ordered one. The discount code get10back still works so it was $620 delivered. Then I saw that JJVW was a big fan and nearly canceled my order. After a few back and forth, I decided fuck it. I have a used antirock for sale now. PM if interested. Would love to have it go to one of the AZ guys.

Edit: Sold the Anti Rock to @Jamison C

Edit: Sold the Anti Rock to @Jamison C

Last edited:

After reading the fantastic review of the ORO Swayloc from @Mr. Bills I jumped on Polyperformance and ordered one. The discount code get10back still works so it was $620 delivered. Then I saw that JJVW was a big fan and nearly canceled my order. After a few back and forth, I decided fuck it. I have a used antirock for sale now. PM if interested. Would love to have it go to one of the AZ guys.

Josh gives out hand jobs for following his advice.