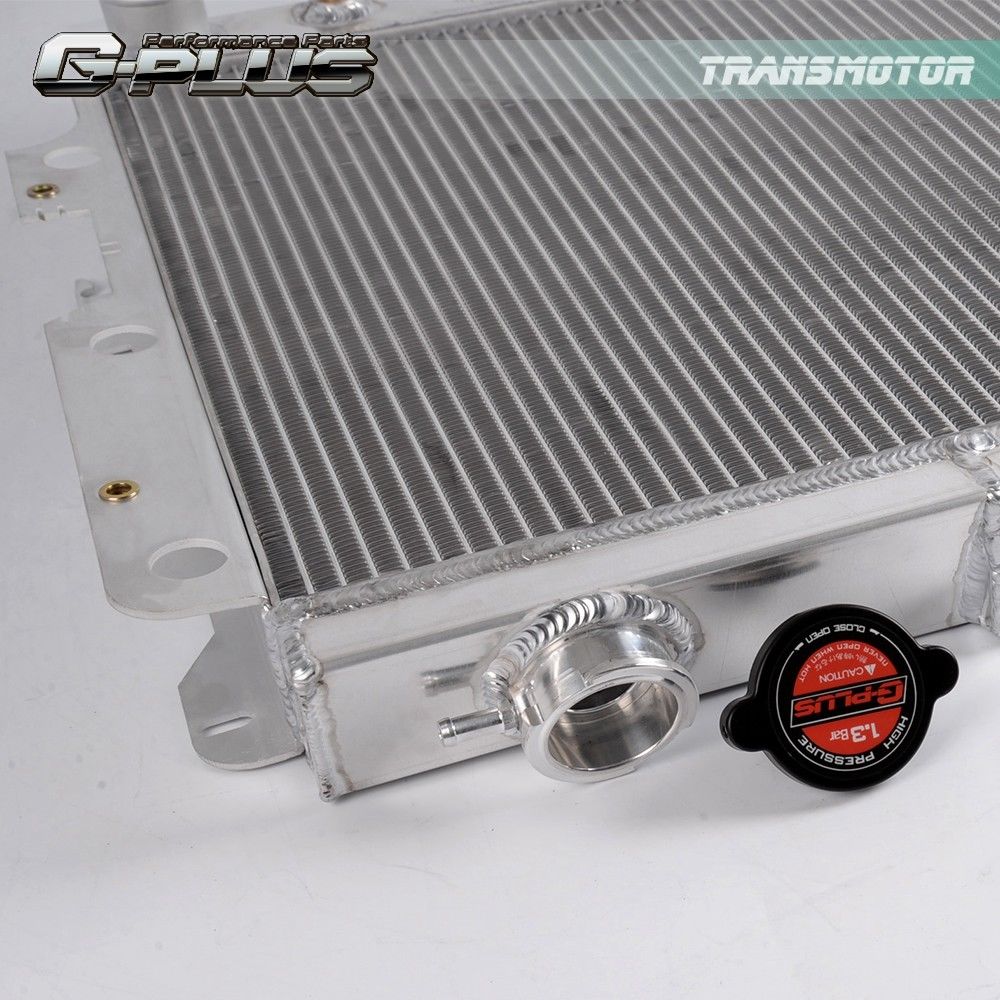

Ordered an aluminum V8 conversion radiator last week, it arrived this evening on my porch. For the most part, I really like OEM radiators by their efficient design (large 1" tubes and aluminum core), except their plastic crimp-on tank design. In the past, I found an outfit that had aluminum replacement tanks available. I had a radiator shop that is no longer in business TIG weld them on to my factory TJ radiator core. However now with the conversion the outlets needed to be reversed and the bottom outlet larger diameter. So I hunted for a suitable replacement that also had RADIATOR FAN SHROUD attachment brackets. Many, in fact most import (and I say cheap import), aftermarket aluminum radiators don't have the proper brackets to re-attach the factory fan shroud. Most don't even have the proper geometry mounting brackets attached at all as I suspect this is because they are a "universal fit" core that get installed in several applications with different mounting tab brackets. In fact I believe the pictures on ebay and Amazon don't even accurately reflect what you will get in most cases and the vendors use "stock" photos that are very misleading! My V8 Magnum conversion will use an original ZJ mechanical thermo-clutch fan and a 4.0L shroud in original configuration for reliability and functionality. I don't want overheating issues PERIOD! I found a decent all TIG welded 3 row core radiator for V8 conversion that has the larger lower fitting and built in cooler in the lower tank patterned after a factory unit. In fact it looks like they tig welded aluminum tanks to a factory radiator except I know this isn't the case because of the "3 row cores". All factory TJ radiators had single core 1" extra large tubes, not two, three or four rows as the aftermarket units all seem to contain. There were a few cross flow radiators that intrigued me but I knew with one of those there would be a substantial amount of "customizing" the fan shroud to fit so it would never look "factory". I ruled these types out even if they may have been more efficient and had a larger core area size.

The above pictures are stock photos from their site but the actual radiator I received looks almost exactly the same. Notice the cooler fittings and the OEM style brackets welded to the radiator that have nutserts for the fan shroud mounting and the cutout for the A/C lines to pass in front of the radiator. All key reasons why I ordered this particular radiator over the others I've seen on the web. Price you ask? Just over $104 shipped to my door!

On another note,

The wiring harness is almost complete. I will try to document its construction very well when I get the chance because there is so little published information out there showing step-by-step or even explaining the process of blending two harnesses together to create one usable emissions legal harness. Everything has to work so it won't trip the MIL indicator and will get the Jeep through the stringent California BAR smog program without failing with something is amiss.

California emissions laws are actually quite straight forward if you follow these simple rules:

1. Any engine swap THE ENGINE has to be EQUAL TO OR NEWER THAN THE RECIPIENT VEHICLE.

2. Any engine swap motor has to be FROM A SIMILAR WEIGHT CLASS VEHICLE.

3. ALL emissions equipment MUST FUNCTION and OF THE TYPE THAT WAS ON THE DONOR MOTOR for it's certification to pass.

4. Any CHECK ENGINE or MIL (Maintenance Indicator Lamp) MUST BE FULLY FUNCTIONAL.

5 On OBD II vehicles with a diagnostic port, THE DIAGNOSTICS PORT MUST BE FUNCTIONAL.

6. Aftermarket emissions related parts MUST POSESS A CALIFORNIA EMISSIONS LEGAL OE TAG or STICKER that is traceable to the manufacturers CA Air Resources Board (CARB) approval letter.

In my swap, the ZJ Grand Cherokee had a LDP (Leak Detection Pump), whereas the TJ Wrangler in 1997 model year did not (1998 and up did have LDP). It used engine manifold vacuum to test and run the fuel vapor recovery system. In order to make my Jeep smog legal for CA, I added the LDP circuitry and parts. Thankfully, there is no EGR system on either the TJ or the ZJ for 1997 model years. I also made sure the Jeep ZJ Grand donor was built AFTER or is NEWER than the TJ Wrangler is. My TJ Wrangler, a 1997, was built on 3/1996. The ZJ Grand donor was built 7/1997, making it one of the last 1997's produced before the 1998 model year builds started in August of 1997. All this makes my engine swap completely legal in the eyes of both the state and the feds!

Again, in my endeavor to make this V8 conversion look as close as possible to a factory option install, I am also adding a few extras my Jeep didn't come with or weren't available options in my model year. One of the biggest add-on options is CRUISE CONTROL which didn't become a factory available option on any TJ Wrangler until the 1998 model year. Since I have parts from my old '98 TJ that I sold off, I had the emissions controls evaporative canister with LDP and solenoid, bracket and lines to retrofit since the ZJ body used an LDP and '97 TJ's did not, I had to add this for smog legality reasons. Also the cruise control cable actuator device mounts to this bracket on the drivers side fender as opposed to the ZJ where it was located on the passenger side fender well near the PDC. I am adding cruise wiring and the smog Leak Detection Pump wiring to the TJ and integrating them to the body harness side like Jeep had done. Instead of using a hacked up totally wrong layout 4-cylinder harness by adding 4 more injectors and changing all the sensor plug ends along with their locations, the decision was made to use the donor ZJ engine harness instead. This entailed changing or blending about a dozen things on the ZJ harness so it would mate to the TJ body harness for both power, dash indicator lamps such as the MIL lamp and the gauges that all run using the CCD twisted pair communications bus.

The following changes had to be made:

Removal of C-131 plug on the ZJ harness

Removal of C-132 plug on the ZJ harness

Integration of C-103 plug from the TJ harness into the ZJ engine harness

Integration of C-104 plug from the TJ harness into the ZJ engine harness

Integration of the generator harness from the TJ harness to the ZJ harness

Removal of the separate ZJ generator power harness and it's C-144 plug from the ZJ harness and motor

Integration of the Transmission Control Relay to the TJ Wrangler PDC on the passenger fender well into an unused relay & fuse spot.

Add a 15 amp fuse in the PDC for the above TCR circuit.

Add the wiring for the cruise control into the cab and under the hood in the TJ body harness.

Replace the '97 TJ Wrangler 4-cylinder ECM with a '98 Dodge Ram 1500 4x4 V8 Auto ECM.

Mount the evap. canister, bracket, LDP and cruise servo assembly to the drivers side fender and connect.

I re-used the 4WD indicator circuit out of the TJ and disconnected but did not remove the 4-wire 4WD-Low/AWD connector from the ZJ engine side harness because that would be too much work to un-loom and remove the extra few wires. They are electrically disconnected and the plug will remain loose, disconnected from anything.

On the ZJ Grand the fuel pump harness is separate and runs in the body of the vehicle. On the TJ, it is attached to the engine harness and crosses over to the frame to go back to the gas tank near the rear axle control arm frame side bracket on the drivers side. I left it independent from the ZJ engine harness as there was no reason to integrate the two as they can be run separate. The fuel pump sender goes through C-103 and so does power to the ECM along with the ASD (Automatic Shut Down relay). In the TJ, the A/C system runs through the C-104 10 pin connector and a separate connector comes from the ECM altogether. On the ZJ harness, the A/C circuit runs through the ECM and PDC separately because it is computer controlled by both the ECM and the BCM that runs the dash controls using the CCD bus. It is much more complicated, therefore I eliminated all the ZJ A/C wiring and kept the TJ climate control harness from C-104. It runs separately from the ZJ engine side harness for simplicity sake.

Plus a few more that will be detailed later.

Changing the ECM was reqired because the ZJ ECM had security in it tied into the BCM computer. Keeping the ZJ ECM would have required me to add the ZJ BCM somewhere to the TJ so it would allow the engine to start and stay running for more than 3 seconds or the ZJ ECM would have shut off believing that the Jeep was in anti-theft mode with the alarm triggered.

I cut the entire under hood harness out of the donor ZJ to get the proper wiring required for adding the transmission relay and cruise control.

I cut the factory TJ Wrangler harness up to re-use connectors C-103 & C-104. C-103 is a 16 pin connector and C-104 is a 10 pin connector.

I added a 3 pin connector to the TJ & ZJ harnesses so I could run some of the transmission control relay wiring through it and still make the entire engine side of the harness removable from the TJ body for separate service capability. If the drivetrain is ever removed, the harness can be unplugged from the ECM and body harness to remain with the engine side of things.

I will edit this some more soon........... It's not finished.