Hard passJosh gives out hand jobs for following his advice.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trail_Krawler & Trail_Willys

- Thread starter kmas0n

- Start date

Brianj5600

TJ Expert

For a little tech... I reworked the exhaust to go above the track bar... It is now up out of harm's way and does not contact the axle or trackbar. This required lowering the frame side track bar mount 2 inches. Theoretically, this will lower the roll center of the rear suspension... about an inch. probably. This should induce slightly more body roll while cornering by giving the axle a little less leverage on the frame... which inversely should slightly reduce the side to side head bob when hitting a rock. I'm not expecting much, but this is in the name of science...

There should also be less bump... shimmy? The side-to-side motion the rear track bar causes.

Stubbornly I hold on to the factory track bar. I adjusted the mount instead so that at halfway through the shocks travel the axle is perfectly centered.

View attachment 261008

Did you notice a difference in the ride quality when you lowered the frame mount for the track bar?

The difference was more than I was expecting. When hitting a pothole or rock with just one rear tire the body of the jeep (and its occupants) had significantly less reaction. scienceDid you notice a difference in the ride quality when you lowered the frame mount for the track bar?

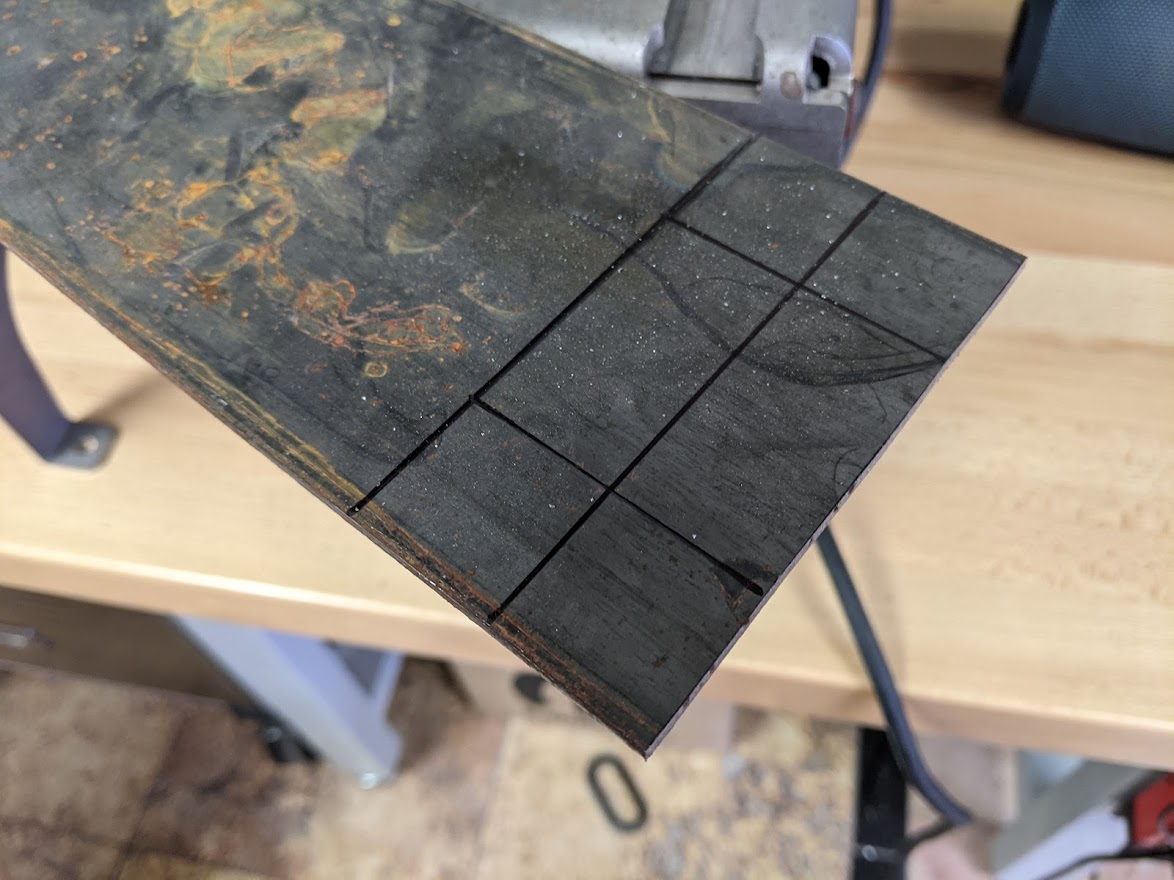

Installed Currie Mini control arm skids. With the axle out of the jeep and drained it was easy to flip it over and get right to everything. I hate welding upside down. The socket and bolt was there to spread the mount slightly so the control arm will still slide into its mount without a hassle. After a few tacks I removed the bolt.

Much Needed Protection

At full bump with only 1" of bumpstop extension. Everything messages perfectly. The track bar does rub the paint off the cover. I could remake the upper control arm with 1.5" DOM and probably gain another 1". Its good to know what your true hard bump is.

And this showed up!

Much Needed Protection

At full bump with only 1" of bumpstop extension. Everything messages perfectly. The track bar does rub the paint off the cover. I could remake the upper control arm with 1.5" DOM and probably gain another 1". Its good to know what your true hard bump is.

And this showed up!

Last edited:

Engine back in again for more mock up. Everything looks good so I'm confident burning in the engine mounts. Still doing a lot of research on fabricating ps hoses, ac hoses, brake lines, fuel lines etc

Last edited:

I've been designing this Jeep around 35" tires for a long time. To keep things simple and uniform across my entire fleet I've chosen to adapt JK/JL wheels. I went with a 17" wheel with a deep dish and enough back spacing to work with the shock outboard. I like the classic look of these from Quadratec.

Full flex...

Full bump (both sides)...

From the rear...

Shock clearance...

Ultimately, I'm planning on a stretch, coilovers and 37's. But that's a ways down the road.

Full flex...

Full bump (both sides)...

From the rear...

Shock clearance...

Ultimately, I'm planning on a stretch, coilovers and 37's. But that's a ways down the road.

Thanks!Nice work. Looks like you’ve covered your bases on the clearance.

I'm at a cross roads here... The obvious choice is blackheart. Long tube, designed to work with thier engine mounts and a 3 link... They look great and it's a simple bolt on. But they are backordered till December!Have you ordered headers and exhaust? Blackheart?

The other option is buying random exhaust manifolds and hoping. I need a rear dump, that points straight down, and hugs the block.

I have seen some of the genright V8 builds use true dual exhaust and both tubes exit straight back, so it's possible to not crossover to the passenger side.

Didn’t realize they were that far outI'm at a cross roads here... The obvious choice is blackheart. Long tube, designed to work with thier engine mounts and a 3 link... They look great and it's a simple bolt on. But they are backordered till December!

The other option is buying random exhaust manifolds and hoping. I need a rear dump, that points straight down, and hugs the block.

I have seen some of the genright V8 builds use true dual exhaust and both tubes exit straight back, so it's possible to not crossover to the passenger side.

THREE-D

New Member

Since I'm removing the butt crack, I figured I may as well raise the rest of the body mounts. They make kits for this kinda thing, but where's the fun in that.

First using a 9" recip saw blade, cut off the body mount.

And clean up the frame.

Bolt the mount back to the body and you will see that between the thickness of the blade and the metal that got ground off of the frame, there is now a 1/8 - 3/16" gap between the frame and mount. I guess you could fill it with weld. Also, the little tab on top doesn't touch the frame. I guess you could fill it with weld.

Or...

and

and then...

So the little bracket fills the gap and wraps up ontop of the frame. I'll trim the bottom off.

Like so...

and...

Then use the welder to put it back on.

and this...

Do it 5 more times and then you have a nearly free body mount puck delete. I'll finish weld it when I have the body off... soon.

First using a 9" recip saw blade, cut off the body mount.

And clean up the frame.

Bolt the mount back to the body and you will see that between the thickness of the blade and the metal that got ground off of the frame, there is now a 1/8 - 3/16" gap between the frame and mount. I guess you could fill it with weld. Also, the little tab on top doesn't touch the frame. I guess you could fill it with weld.

Or...

and

and then...

So the little bracket fills the gap and wraps up ontop of the frame. I'll trim the bottom off.

Like so...

and...

Then use the welder to put it back on.

and this...

Do it 5 more times and then you have a nearly free body mount puck delete. I'll finish weld it when I have the body off... soon.

5632

Love me some Target!!!

That's the first time I have ever seen a Jeep with a hood and no fenders.Thanks for sharing your build! One of my projects follows the same build philosophy.View attachment 273434

Been talking to a few people. It's been suggested to me to use late model Camero exhaust manifolds, but use a passenger side manifold in the driver's side and route the exhaust between the engine mount and power steering pump... There is certainly room if you get the right manifold.Have you ordered headers and exhaust? Blackheart?

That blackheart just looks so similar to what’s on the tj now. I read the thread with the guy that designed it and he seemingly put quite a bit of thought into it. JK gear and gadgets used it on their LJ I believe.Been talking to a few people. It's been suggested to me to use late model Camero exhaust manifolds, but use a passenger side manifold in the driver's side and route the exhaust between the engine mount and power steering pump... There is certainly room if you get the right manifold.